Efficient straw extrusion crystallization system and method

A technology of crystallization system and straw, which is applied in the field of high-efficiency straw extrusion crystallization system, can solve the problems of poor roundness of crystallization, low crystallization efficiency, and inability to reduce production costs, and achieve fast distribution, increase crystallization efficiency, and improve crystallization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

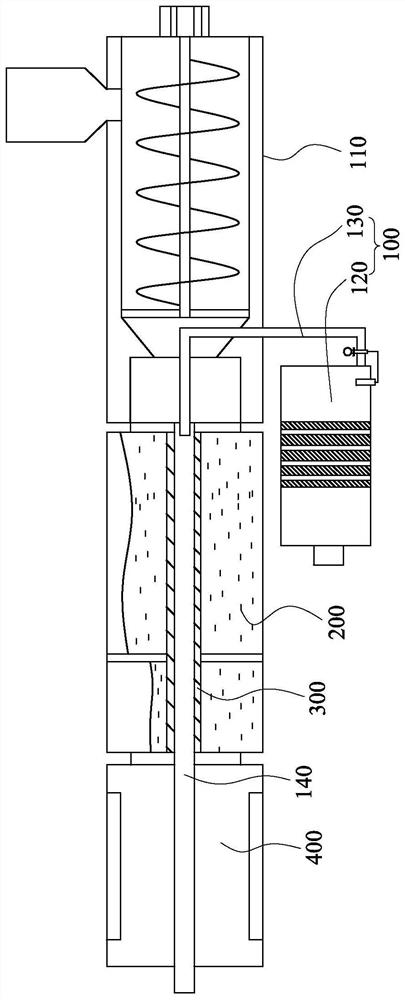

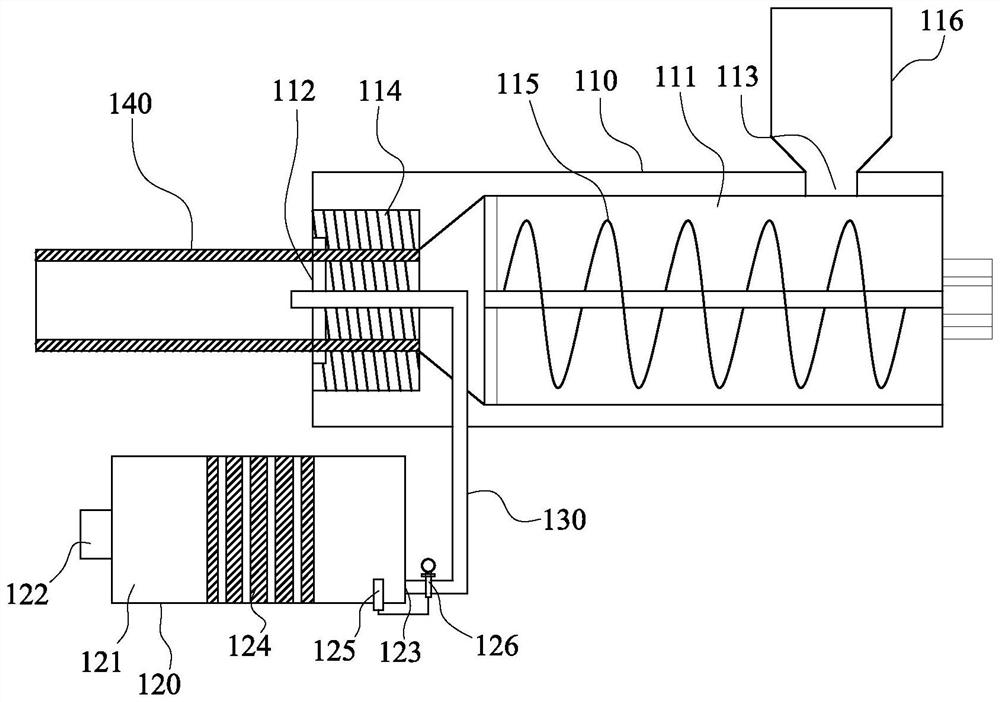

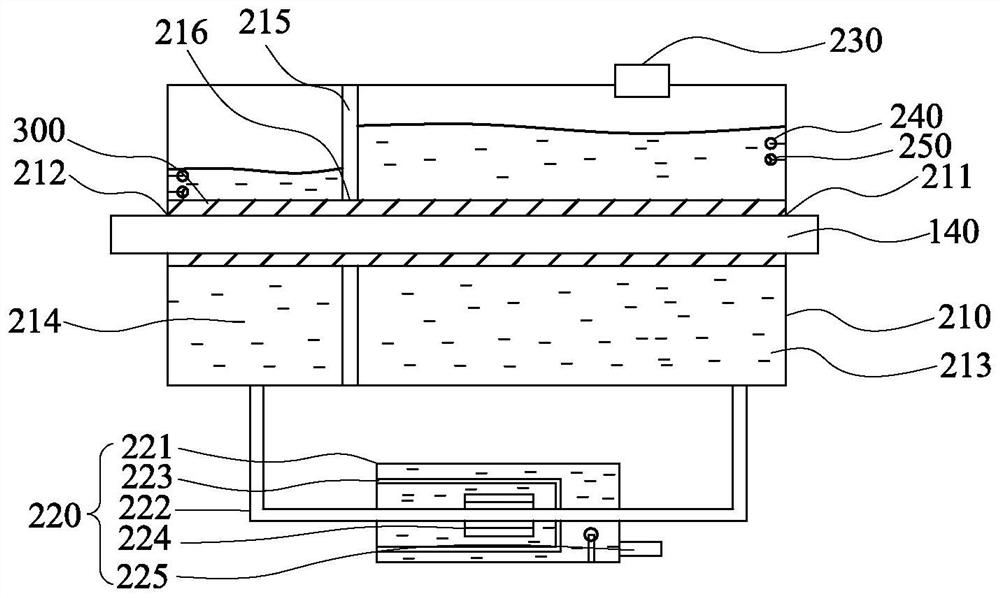

[0050] see Figure 1 to Figure 3 , which is a structural schematic diagram of a high-efficiency straw extrusion crystallization system provided by the present invention. An efficient straw extrusion crystallization system includes: an extruder 110 for extruding a straw piece 140, and a crystallization device for heating and crystallizing the outer wall of the straw piece. Specifically, the crystallization device in this embodiment is a hot water heating crystallization device. Specifically, the hot water heating crystallization device includes a crystallization water tank 200 for storing crystallization water. After the extruder 110 is extruded and molded, the suction pipe piece 140 that is continuously output runs through the crystallization water tank 200, and the water stored in the crystallization water tank 200 contributes to the continuous output. The suction pipe part 140 is subjected to constant temperature water crystallization treatment; the crystallization radial r...

Embodiment 2

[0077] Based on the high-efficiency straw extrusion crystallization system described above in Embodiment 1, this embodiment also provides a straw extrusion crystallization method including the following steps:

[0078] S1, extruding tube forming, using the extruder 110 to extrude and form the continuous output straw piece 140;

[0079] S2, crystallization of the inner and outer walls, the continuous output suction pipe 140 enters constant temperature water, the constant temperature water crystallizes the outer wall of the continuous output suction pipe 140, and inputs constant temperature hot air into the continuous output suction pipe 140 to continuously output the suction pipe 140 The inner wall undergoes crystallization;

[0080] S3, external crystallization, the continuous output straw piece 140 is re-crystallized by non-contact heating crystallization after being treated in S2;

[0081] S4. Cutting. The continuous output straw piece 140 after the treatment in S3 is cut t...

Embodiment 3

[0084] The structure and principle of this embodiment are basically the same as those of Embodiment 1, except that the crystallization device is an electric heating crystallization device, for example, a structure in which several electric heating tubes are distributed around the periphery of the suction pipe member 140 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com