Automatic preparation system of microbial fertilizer

A microbial fertilizer and preparation system technology, which is applied in the field of automatic preparation system of microbial fertilizer, can solve the problems of soil quality decline, environmental pollution, etc., and achieve the effects of saving production resources, improving product quality, and optimizing production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

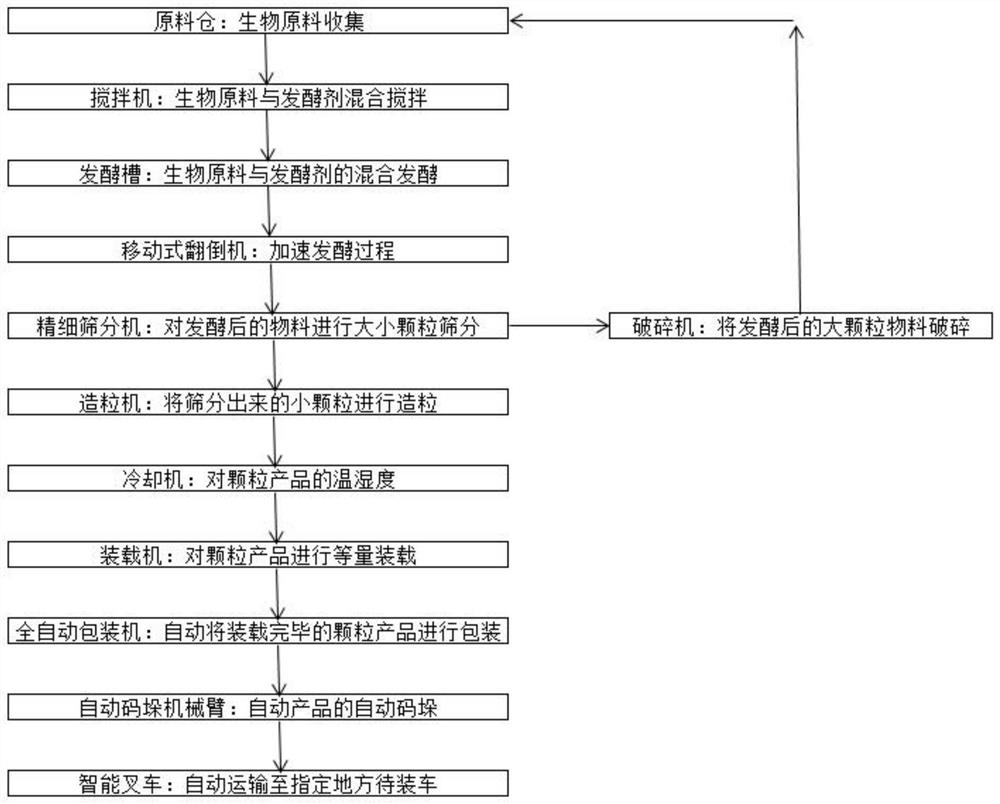

[0023] as attached figure 1 As shown, an automated preparation system for microbial fertilizers, including raw material bins, mixers, fermentation tanks, mobile tipping machines, fine screening machines, crushers and granulators, raw material bins, mixers, fermentation tanks and mobile tipping machines The machine is connected by a conveyor belt. The collected poultry manure, straw and other biological materials are accumulated in the raw material warehouse. The straw needs to be crushed and then stacked in the raw material warehouse. By reusing poultry manure and other pollutants, it is beneficial to increase the income of poultry farmers. , At the same time, it is also convenient to expand the production capacity of microbial fertilizers. An aeration device is installed at the bottom of the fermentation tank, and the aeration device can be used to increase oxygen and heat the materials in the fermentation tank according to the temperature and humidity conditions, which is co...

Embodiment 2

[0029] The difference between this embodiment and Embodiment 1 is that the outlet of the cooling machine is connected with a "Y"-shaped connecting pipe, and two valves are installed on the connecting pipe. One outlet of the connecting pipe is connected to the loader, and the other of the connecting pipe is The exit is connected to a secondary storage and chemical box through a conveyor belt. The secondary storage and chemical box is equipped with drying equipment electrically connected to the PLC control system, multiple temperature and humidity sensors and electronic weighing devices. Multiple temperature and humidity sensors are evenly distributed in the In the secondary storage and chemical tank, the electronic weighing device is arranged at the bottom of the secondary storage and chemical tank.

[0030] The difference between this embodiment and the working process of Embodiment 1 is that this embodiment can maintain the continuous production of microbial fertilizer, mainta...

Embodiment 3

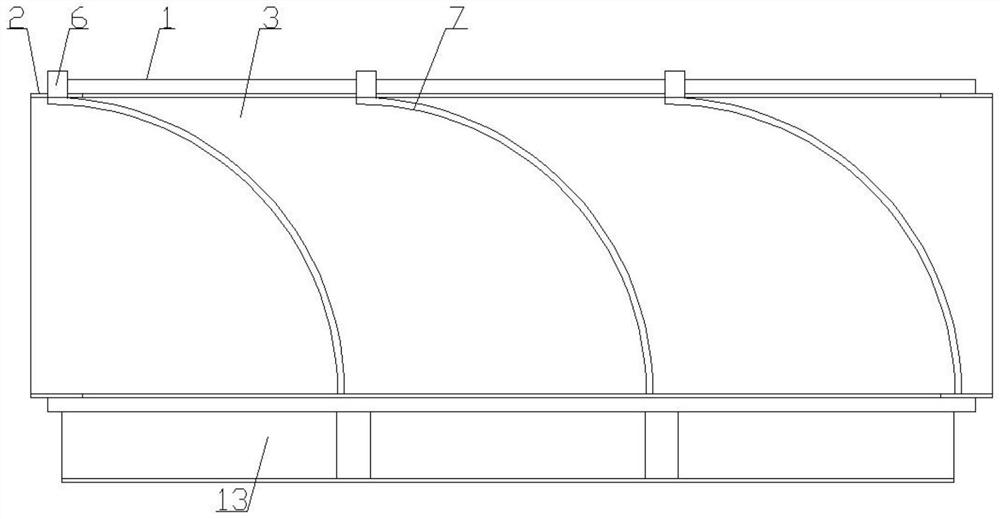

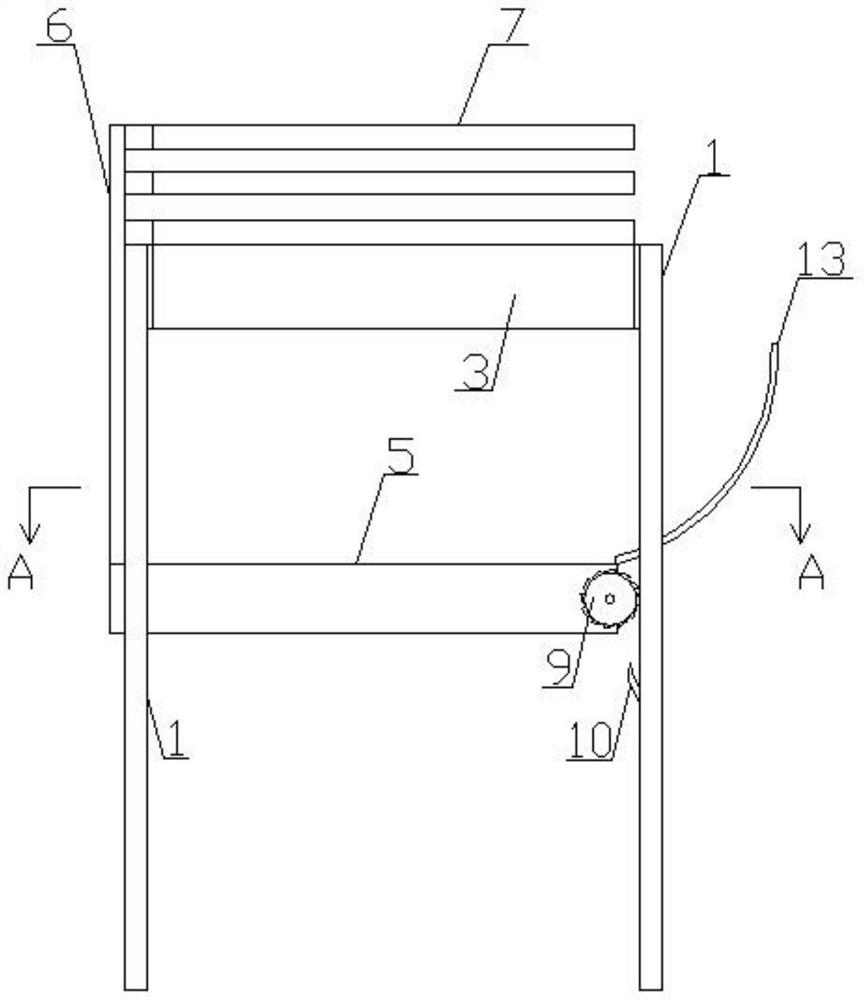

[0032] as attached Figure 2 to Figure 4 As shown, the difference between this embodiment and embodiment 2 is only that the number of fermentation tanks in this embodiment is not less than 2, and the number of fermentation tanks in this embodiment is 3, and the 3 fermentation tanks are arranged in parallel with each other at intervals. The same side of all fermentation tanks is provided with a supporting frame 1. The supporting frame 1 is composed of a rectangular frame and legs welded on the four corners of the rectangular frame. Each leg is rotatably connected with a pulley, and the pulley is slidably connected on the slide rail. Both sides of the rectangular frame are rotatably connected with rollers 2, and a horizontal conveyor belt 3 connected to the mixer is tensioned between the two rollers 2. A vertical conveyor belt above the horizontal conveyor belt is also installed between the mixer and the horizontal conveyor belt. There is a fixed frame welded on the same side le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com