A kind of modified polycarboxylate water reducing agent and preparation method thereof

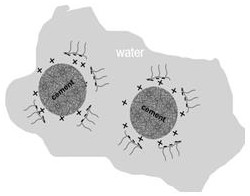

A technology of water reducer and polycarboxylate, which is applied in the field of modified polycarboxylate water reducer and its preparation, which can solve the problems of reducing mortar fluidity, accelerating concrete slump loss, and dispersibility without water-locking properties. , to achieve long-lasting anti-mud performance, make up for mud sensitivity, and long-lasting water-locking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of a modified polycarboxylate water reducer, comprising the steps of:

[0043] (1) Polyether modification: react 3g of 2-naphthol-3,6-disulfonic acid with 27g of polyether at 120°C for 2 hours to obtain a modified polyether;

[0044] (2) Synthesis of water reducer: Add 61g of modified polyether to 60g of water to dissolve evenly, add 1.5g of hydrogen peroxide to it and stir evenly, then add 0.2g of sodium hypophosphite to it, mix evenly to obtain liquid A, mix 8g After mixing acrylic acid and 0.15g Vc evenly, add 20g water to it and mix evenly to obtain liquid B, add liquid B dropwise to liquid A for 3 hours, and keep warm for 2 hours after the dropwise addition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com