Quenching method for large shaft forgings with 3% Ni content

A 3%ni, 1.3%ni technology, applied in the field of quenching, can solve problems such as affecting the quenching effect, and achieve the effect of high quenching effect, excellent performance and good quenching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] The method for quenching large shaft forgings with 3% Ni content of the present invention comprises the following steps

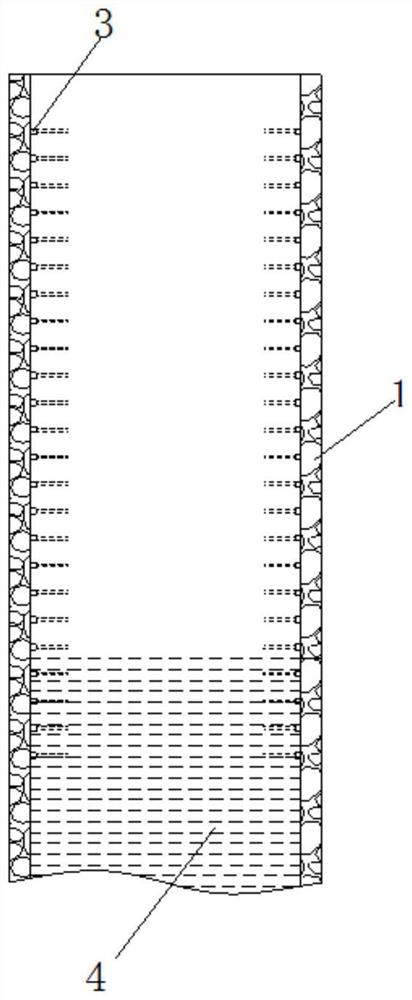

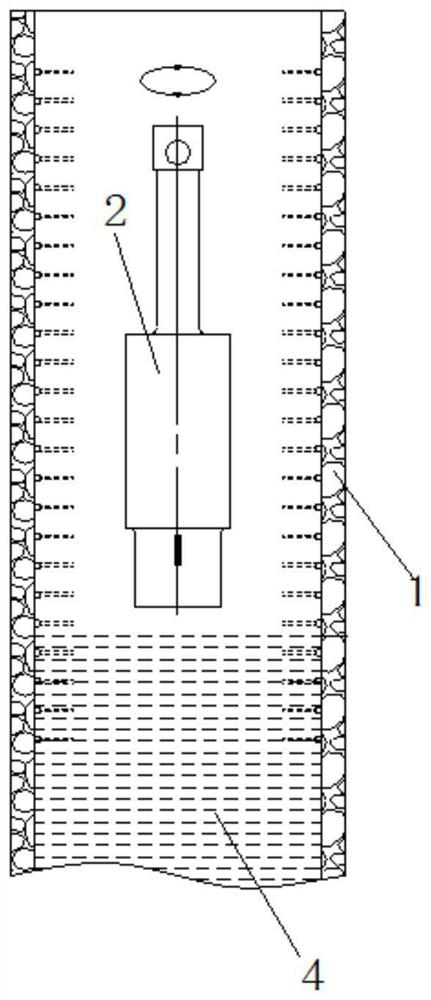

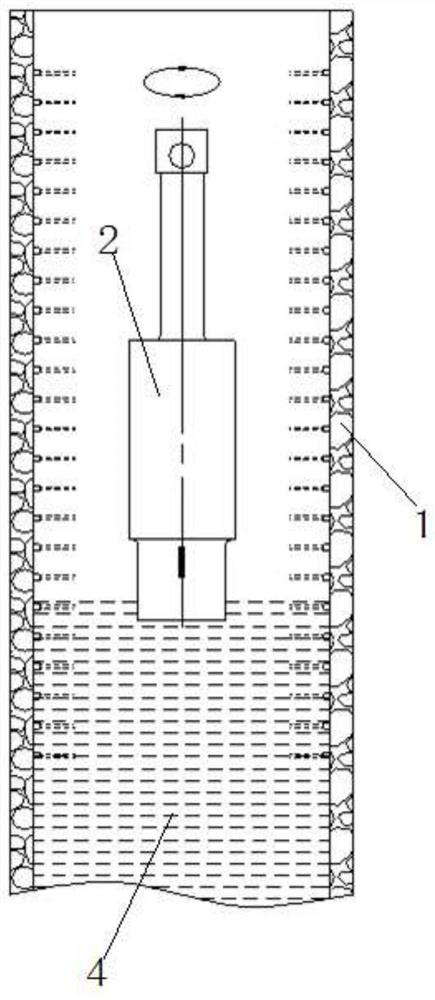

[0023] A, the quenching liquid is passed into the bottom of the vertical spray quenching device 1 to form a quenching liquid pool 4, such as figure 1 As shown, the liquid level of the quenching liquid pool 4 is located at the first process height. The vertical spray quenching device 1 is similar to a water well, and is arranged under the ground, thereby saving the space on the ground, so that the large-sized shaft forging 2 can be hoisted into the vertical spray quenching device 1 . The vertical spray quenching device 1 has a larger diameter and depth, and is used for quenching large shaft forgings 2 . The side wall of the vertical spray quenching device 1 is covered with nozzles 3, which are connected to the quenching liqu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap