Tunneling equipment, steel arch assembly splicing system and control method

A tunnel excavation and steel arch technology, which is applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of high labor intensity, high safety hazards, and low construction efficiency, and achieve high operation accuracy and high construction efficiency. Effects on safety and health, labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The core of the present invention is to provide a steel arch assembly assembly system, which has high operating precision and high construction efficiency, and can correspondingly reduce the labor intensity and safety risks of the staff; at the same time, it provides A tunnel excavation equipment using the steel arch assembly assembly system and a control method for the steel arch assembly assembly system using the tunnel excavation equipment.

[0055] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0056] Please refer to Figure 1 to Figure 16 .

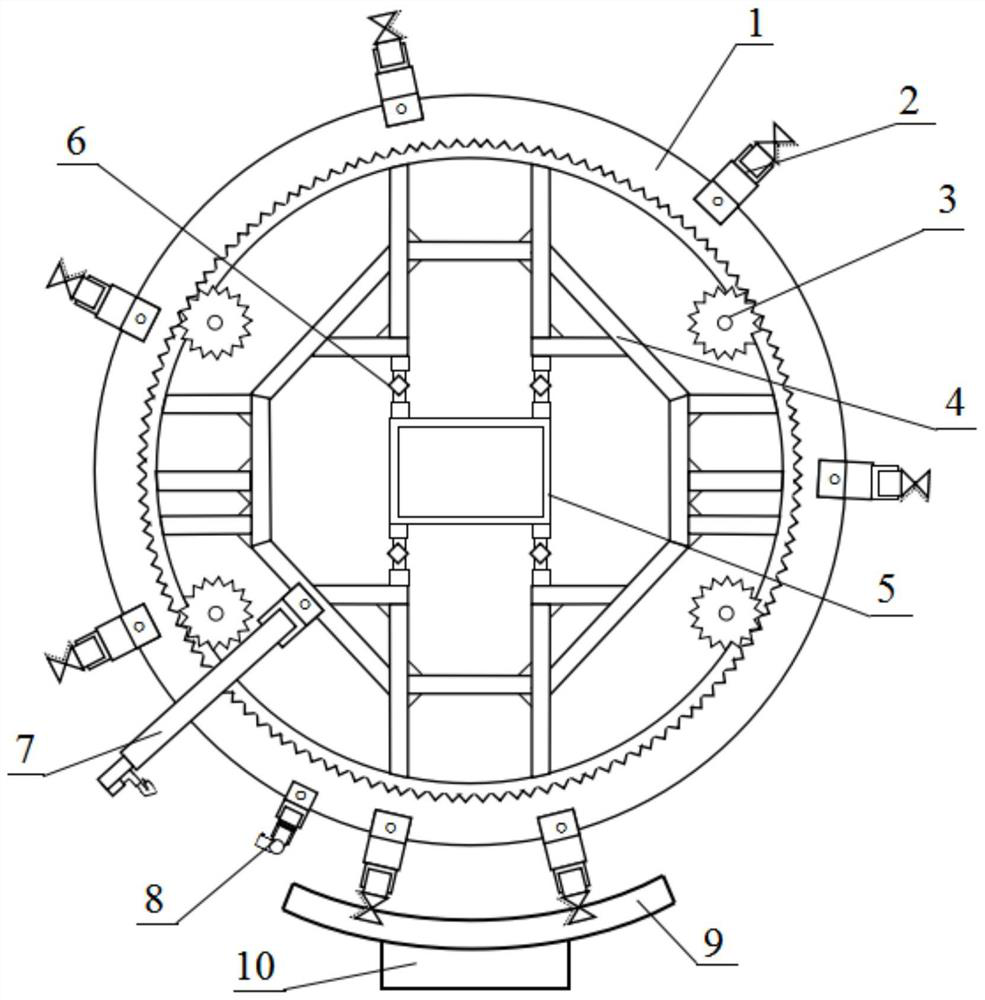

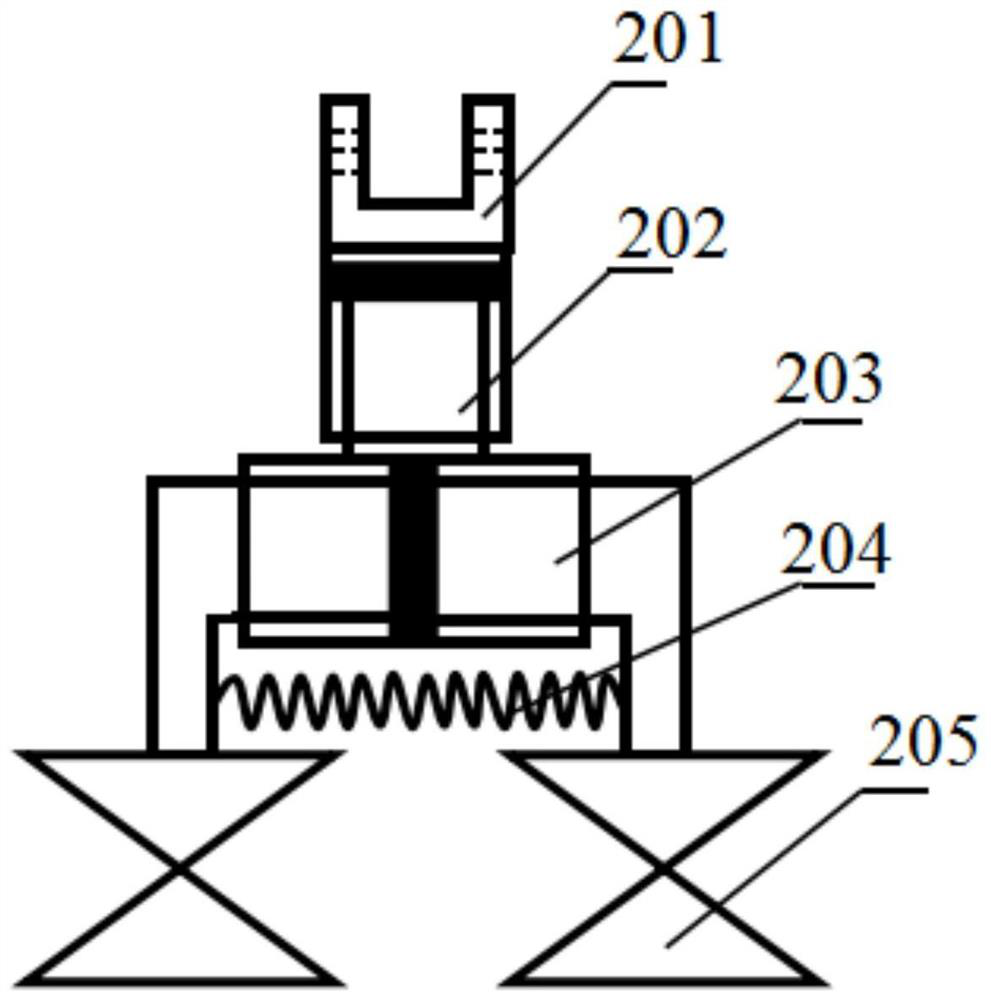

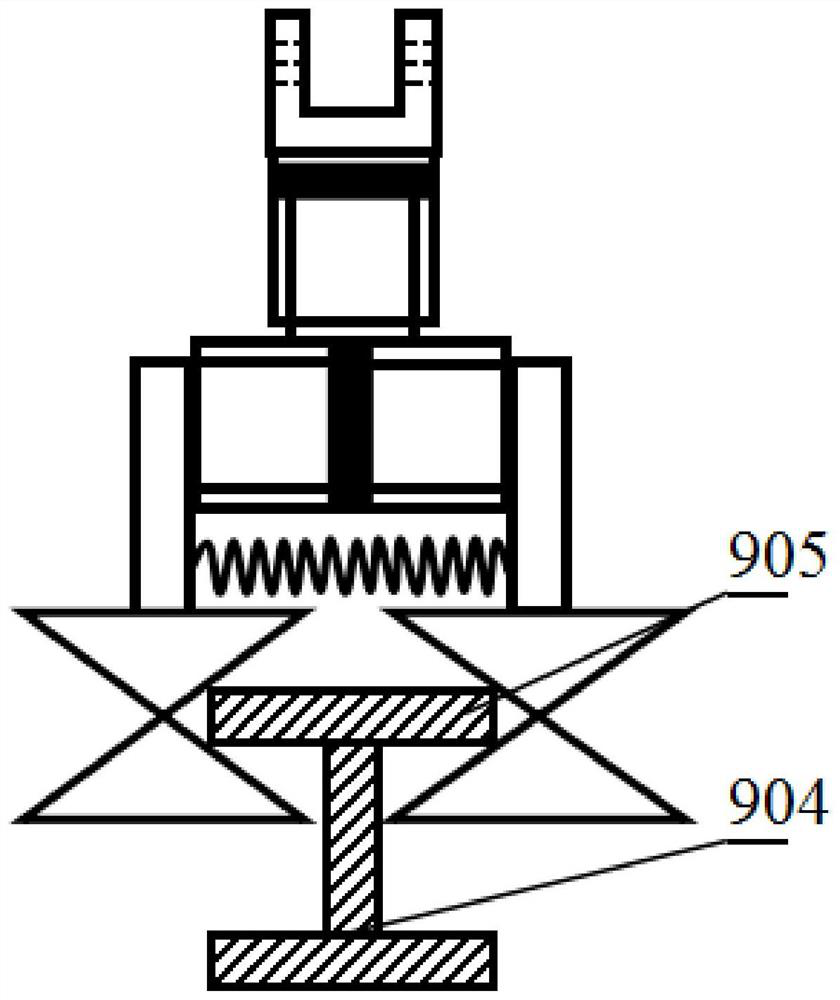

[0057] In a specific embodiment, the steel arch assembly assembly system provided by the present invention includes a main girder 5 extending along the direction of tunnel excavation. The outer peripheral part of the main girder 5 mov...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap