Axial flow compression expansion type energy conversion device and control method

An energy conversion device, compression and expansion technology, which is applied to parts of pumping devices for elastic fluids, pump devices, axial flow pumps, etc., can solve the problem of low power level of the energy storage system, reduce energy loss, The effect of reducing radial offset and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

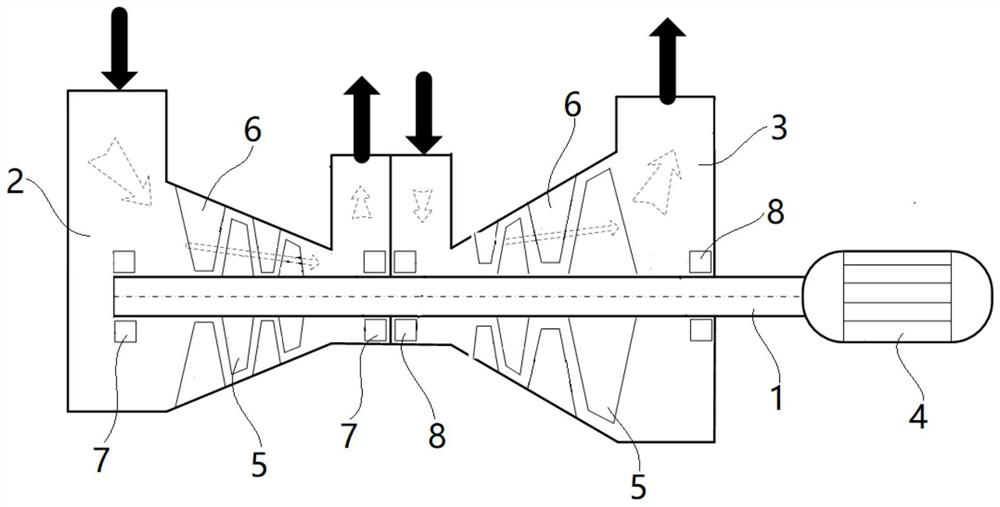

[0037] The axial-flow compression-expansion energy conversion device provided in this embodiment includes: a rotor shaft 1 , a compression cylinder 2 , an expansion cylinder 3 and a motor generator 4 .

[0038] Such as figure 1 As shown, the rotor shaft 1 has two sets of movable blades 5 arranged at intervals, and each group of multi-stage movable blades 5 includes two movable blades 5 arranged at intervals, and each movable blade 5 is vertically connected to the end of the rotor shaft 1 Zhou Xiang. The compression cylinder 2 has an inlet / exhaust port communicating with the outside world, and two-stage vanes 6 arranged at intervals on its inner wall; the expansion cylinder 3 has an inlet / exhaust port communicating with the outside world, and has intervals on its inner wall The two-stage static vane 6 that is set. Both the axial direction of the compression cylinder 2 and the expansion cylinder 3 have piercing holes, and the rotor shaft 1 penetrates into the interior of the c...

Embodiment 2

[0047] The control method for converting pressure energy and electric energy provided in this embodiment includes the following steps:

[0048] Pass low-pressure gas into the compression cylinder 2, after multi-stage compression, rise to high-pressure gas and discharge;

[0049] Pass high-pressure gas into the expansion cylinder 3, and after multi-stage expansion, it will be reduced to low-pressure gas and discharged;

[0050] When the compression power consumption of the compression cylinder 2 is greater than the expansion power production of the expansion cylinder 3, the motor generator 4 is switched to the output mode (as an electric motor) to provide power for the rotor shaft 1;

[0051] When the compression work of the compression cylinder 2 is less than the expansion work of the expansion cylinder 3, the motor generator 4 is switched to the input mode (as a generator), absorbing the mechanical energy of the rotor shaft 1 and converting it into electrical energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com