Optical film, polarizing plate, and method for manufacturing optical film

A technology of optical film and manufacturing method, which is applied in the direction of optics, optical elements, polarizing elements, etc., can solve the problems of optical film hue change, damage to display quality, appearance deterioration, etc. Excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

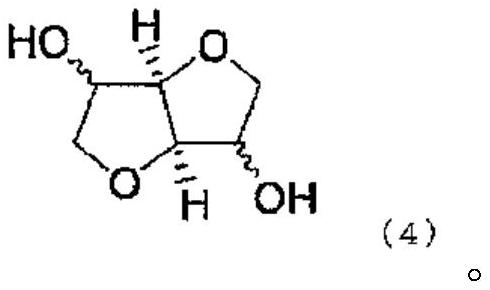

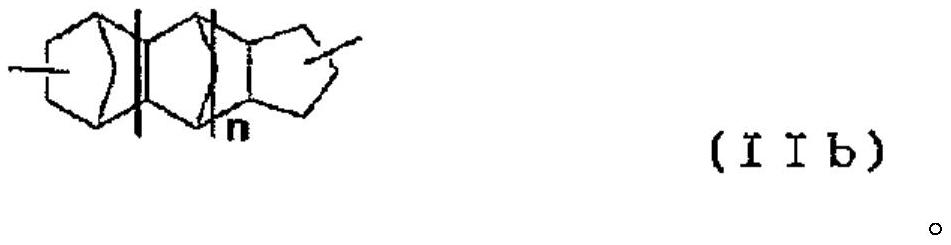

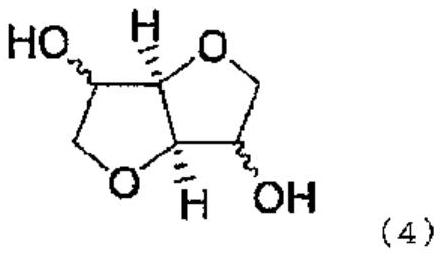

[0118] In a reaction vessel, 47.19 parts by mass of tricyclodecane dimethanol (abbreviated as "TCDDM" below) and 81.98 parts by mass of isosorbide (hereinafter sometimes abbreviated as "ISB"), diphenyl carbonate (hereinafter sometimes abbreviated as Abbreviated as "DPC") 175.1 parts by mass and 0.979 parts by mass of cesium carbonate 0.2 mass % aqueous solution as a catalyst, under a nitrogen atmosphere, as the first stage of the reaction, heat the temperature of the heating tank to 150 ° C, stirring as needed While allowing the ingredients to dissolve (approximately 15 minutes). Next, the pressure was increased from normal pressure to 13.3 kPa, and the temperature of the heating tank was raised to 190° C. over 1 hour, and the generated phenol was taken out of the reaction vessel. After keeping the entire reaction vessel at 190°C for 15 minutes, as a second-stage process, set the pressure in the reaction vessel to 6.67kPa, raise the temperature of the heating tank to 230°C ove...

Embodiment 2

[0120] An optical film was obtained in the same manner as in Example 1 except that the film forming line speed was 8 m / min and the thickness was 30 μm. The degree of orientation of the obtained optical film was 5.7%, and the in-plane retardation Re(550) was 3 nm. The obtained optical film was subjected to the same evaluation as in Example 1. The results are shown in Table 1.

Embodiment 3

[0122] An optical film was obtained in the same manner as in Example 1, except that the birefringence Δnxy of the polycarbonate resin was 0.018, the film-forming linear velocity was 10 m / min, and the thickness was 20 μm. The degree of orientation of the obtained optical film was 6.1%, and the in-plane retardation Re(550) was 2 nm. The obtained optical film was subjected to the same evaluation as in Example 1. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com