Method for identifying a cell thermal dissipation of a power battery of a motor vehicle, battery warning

A battery cell and power battery technology, applied in the direction of battery, driving interaction, electric vehicle, etc., can solve the problem that the temperature value cannot be transmitted in real time, cannot determine the excessive temperature of the cell, and cannot determine the sensor failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The examples set forth below are preferred embodiments of the invention. In the exemplary embodiments, the parts described in the embodiment are each individual feature of the invention which can be considered independently of one another and which also respectively improve the invention independently of one another. Accordingly, the disclosure is intended to cover combinations of the features of the embodiments in addition to those shown. Furthermore, the described embodiments can also be supplemented by other features of the invention which have already been described.

[0031] In the figures, identical reference numerals denote functionally identical elements, respectively.

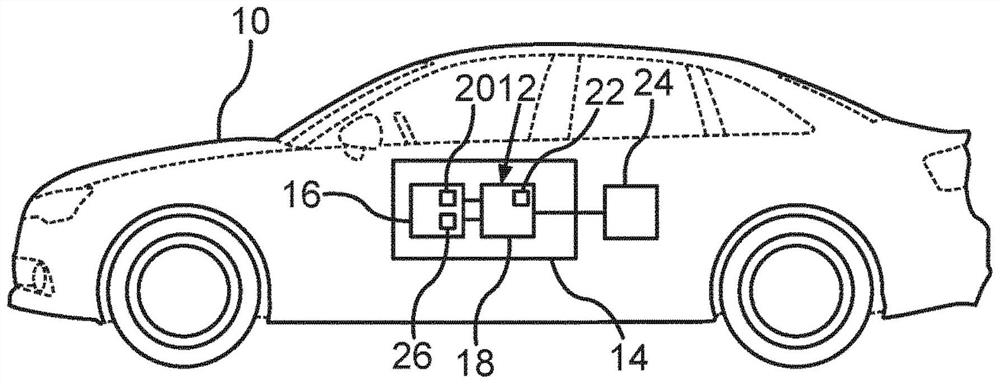

[0032] exist figure 1 A motor vehicle 10 with a battery warning system 12 according to an exemplary embodiment is shown in FIG. Motor vehicle 10 may be an electrically driven motor vehicle 10 having a power cell 14 . Traction battery 14 may comprise a battery module, wherein the battery modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com