Polymeric micelle freeze-drying preparation of taxane antitumor drugs for injection

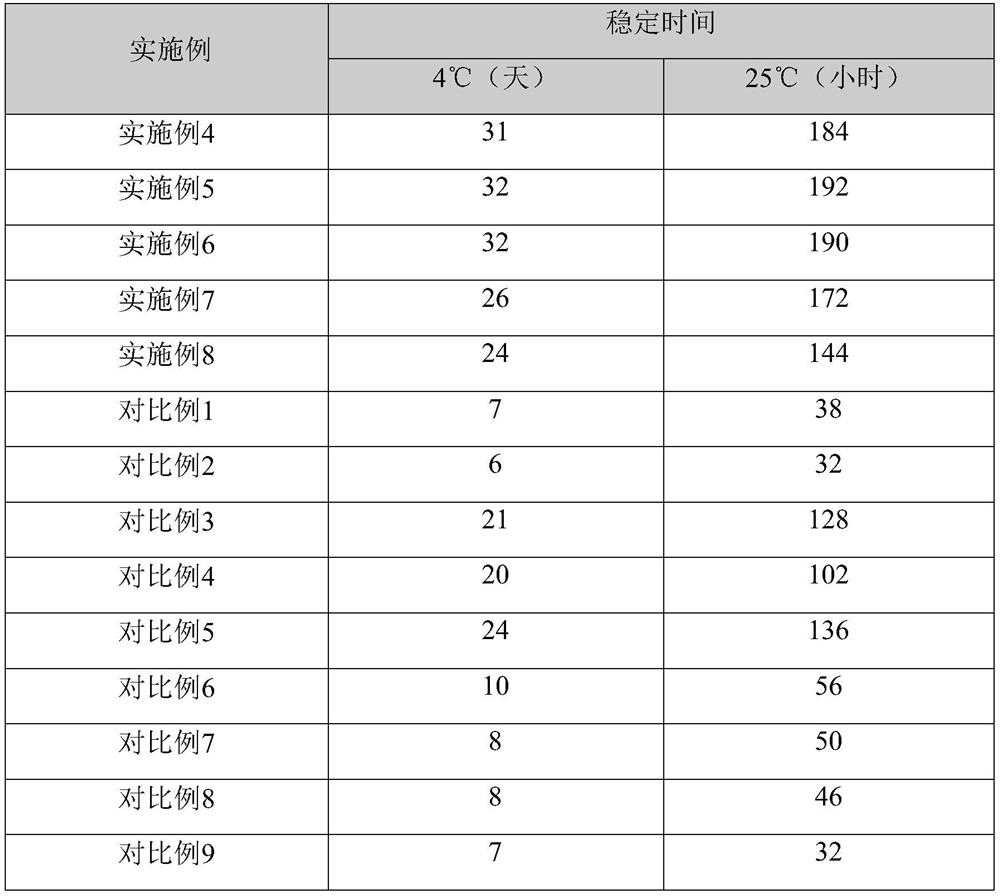

An anti-tumor drug and polymer glue technology, which is applied in the field of taxane polymer micelle freeze-dried preparations, can solve the problems of unsatisfactory applicability universality, unsatisfactory stabilization time, unobvious improvement of micelle stability, and the like, To achieve the effect of improving stability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 polyethylene glycol-polyorthoester block copolymer

[0035] Under the protection of nitrogen, add polyethylene glycol to the glass polymerization bottle 200070g, keep stirring at 125~130°C and vacuumize to remove water for 4h; add stannous isooctanoate (0.5g) / toluene solution, stir and disperse for 30min, keep stirring at 125~130°C and vacuumize toluene for 1.5h; add polyorthoester 30g , 125 ~ 130 ℃ heat preservation and stirring reaction for 3 ~ 4h; after the reaction is completed, cool down, add dichloromethane and stir to dissolve, add metal scavenger for three times. Suction filtration, filter out the metal scavenger, add the filtrate to anhydrous ether, dissolve and crystallize twice; dissolve with dichloromethane, filter through a PTFE membrane (3 μm), add the filtrate to anhydrous ether to crystallize; the obtained product First vacuum dry at -0.08~-0.1MPa below 20°C for 6 hours, turn over the material, and then control the temper...

Embodiment 2

[0036] The preparation of embodiment 2 polyethylene glycol monomethyl ether-poly (D, L) lactide block copolymer

[0037] Under the protection of nitrogen, add polyethylene glycol monomethyl ether to the glass polymerization bottle 2000 50g, keep stirring at 125~130°C and vacuumize to remove water for 4h; add stannous isooctanoate (0.128g) / toluene solution, stir and disperse for 30min, keep stirring at 125~130°C and vacuumize toluene for 1.5h; add DL-lactide 50g, keep stirring at 125-130°C for 3-4 hours; after the reaction, cool down, add dichloromethane and stir to dissolve, add metal scavenger for three times. Suction filtration, filter out the metal scavenger, add the filtrate to anhydrous ether, dissolve and crystallize twice; dissolve with dichloromethane, filter through a PTFE membrane (3 μm), add the filtrate to anhydrous ether to crystallize; the obtained product First vacuum dry at -0.08~-0.1MPa below 20°C for 6 hours, turn over the material, and then control the tem...

Embodiment 3

[0038] The preparation of embodiment 3 polypropylene glycol-polyglycolide-lactide block copolymer

[0039] Under the protection of nitrogen, add polypropylene glycol to the glass polymerization bottle 1000 30g, keep stirring at 125~130℃ and vacuumize for 4h to remove water; add stannous octanoate (0.05g) / toluene solution, stir and disperse for 30min, keep stirring at 125~130℃ and vacuumize to remove toluene for 1.5h; add polyglycolide 70g lactide, heat-retain and stir at 125-130°C for 3-4 hours; cool down after the reaction, add dichloromethane and stir to dissolve, add metal scavenger for three times. Suction filtration, filter out the metal scavenger, add the filtrate to anhydrous ether, dissolve and crystallize twice; dissolve with dichloromethane, filter through a PTFE membrane (3 μm), add the filtrate to anhydrous ether to crystallize; the obtained product First vacuum dry at -0.08~-0.1MPa below 20°C for 6 hours, turn over the material, and then control the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com