Steel-making method of ultra-low carbon steel

A technology of ultra-low carbon steel and converter smelting, which is applied in the manufacture of converters, casting molten material containers, manufacturing tools, etc. It can solve problems such as crystallizer liquid level fluctuations, reduce oxidation in slag, reduce secondary oxidation, The effect of reducing sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Steel for automobile O5 plates was smelted in 6 furnaces for 1 casting, and the converter was produced according to the high-drawing carbon process. The carbon content and oxygen content at the end point of the converter are shown in Table 3. Combined with the oxygen content at the end of the converter, the converter top slag modification is dynamically adjusted, and the specific modifier addition amount is shown in Table 3.

[0043] table 3

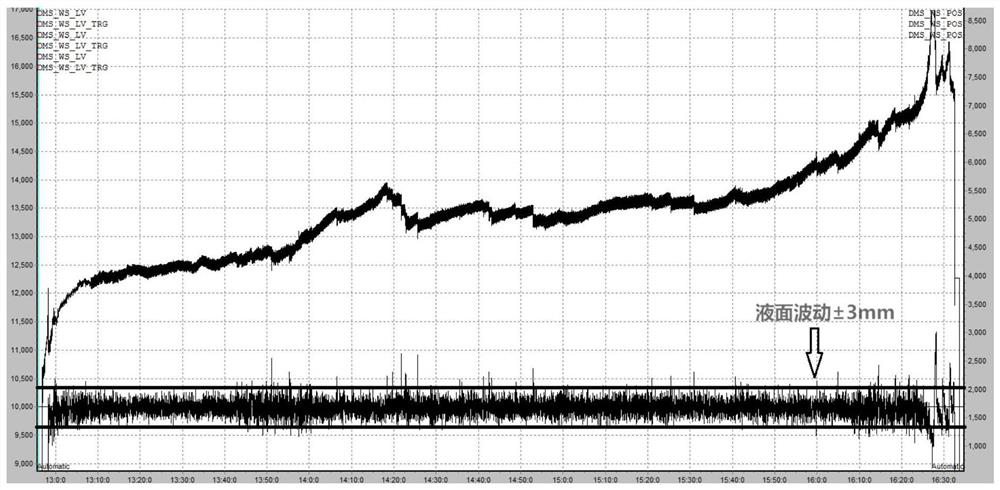

[0044]

[0045] Through the above dynamic top slag modification, the RH inbound and outbound TFe of 6 furnaces of high value-added automotive O5 plates are well controlled, with an average RH inbound TFe content of 3.8%, and an average RH outbound TFe content of 5.2%.

[0046] The bell-type long nozzle is used for submerged casting under the liquid surface to reduce the probability of secondary oxidation of molten steel during casting.

[0047] The cover is argon-sealed throughout the whole process. Oxygen is blown on the cove...

Embodiment 2

[0051] 8 furnaces of steel for automobile O5 plates were smelted in 1 casting time, and the converter was produced according to the high-drawing carbon process. The carbon content and oxygen content at the end point of the converter are shown in Table 4. Combined with the oxygen content at the end of the converter, the converter top slag modification is dynamically adjusted, and the specific modifier addition amount is shown in Table 4.

[0052] Table 4

[0053]

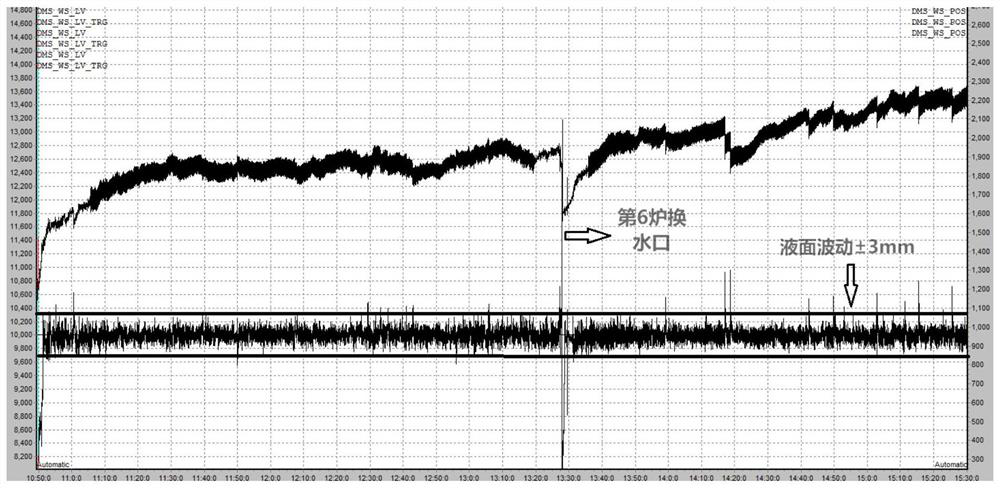

[0054] Through the above-mentioned dynamic top slag modification, the RH inbound and outbound TFe control of the high value-added automobile O5 plate of the 8 furnaces is stable, the average TFe content of RH inbound is 3.25%, and the average TFe content of RH outbound is 4.7%.

[0055] The bell-type long nozzle is used for submerged casting under the liquid surface to reduce the probability of secondary oxidation of molten steel during casting.

[0056] The cover is argon-sealed throughout the whole process. Oxy...

Embodiment 3

[0060] Steel for automobile O5 plates was smelted in 8 heats for 1 casting, and the converter was produced according to the high-drawing carbon process. The carbon content and oxygen content at the end point of the converter are shown in Table 5. Combined with the oxygen content at the end of the converter, the converter top slag modification is dynamically adjusted, and the specific modifier addition amount is shown in Table 5.

[0061] table 5

[0062]

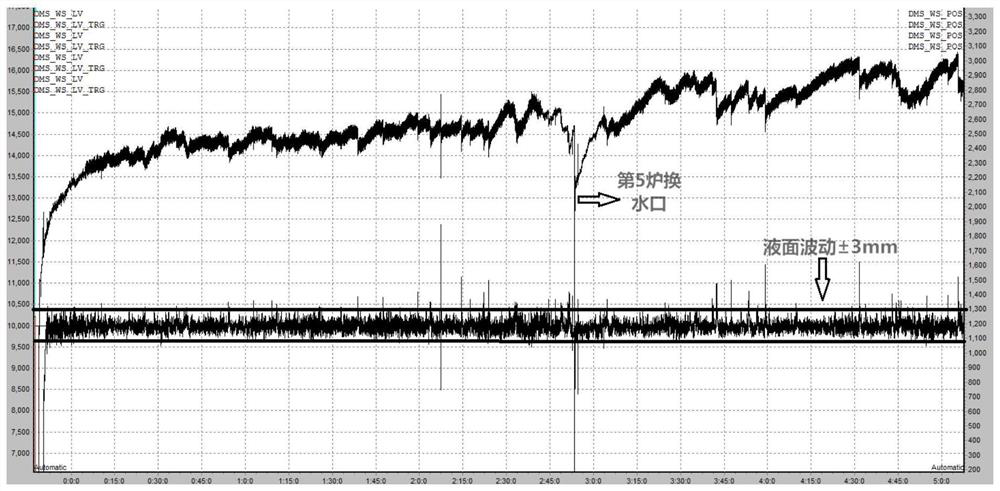

[0063] Through the above-mentioned dynamic top slag modification, the RH inbound and outbound TFe control of 8 furnaces of high value-added automobile O5 plates is stable, the average TFe content of RH inbound is 2.9%, and the average TFe content of RH outbound is 4.8%.

[0064] The bell-type long nozzle is used for submerged casting under the liquid surface to reduce the probability of secondary oxidation of molten steel during casting.

[0065] The cover is argon-sealed throughout the whole process. Oxygen is blown on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com