Water circulation gravity engine utilizing high-pressure air compression bin

A technology of high-pressure air and compression chambers, which is applied in hydropower, engine components, machines/engines, etc., can solve the problems of huge construction costs, high costs, and non-recyclable energy consumption, etc., to achieve cost reduction. Huge, the effect of solving the gradual depletion of fossil energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

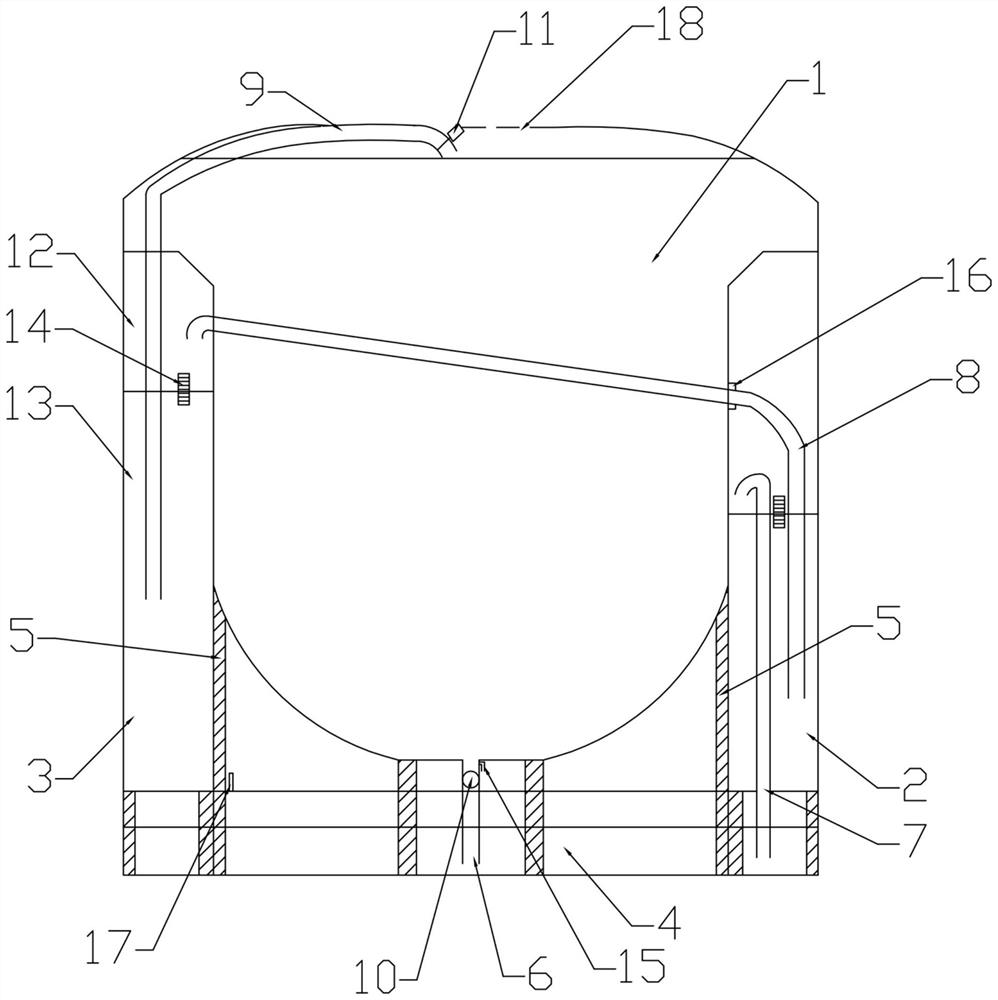

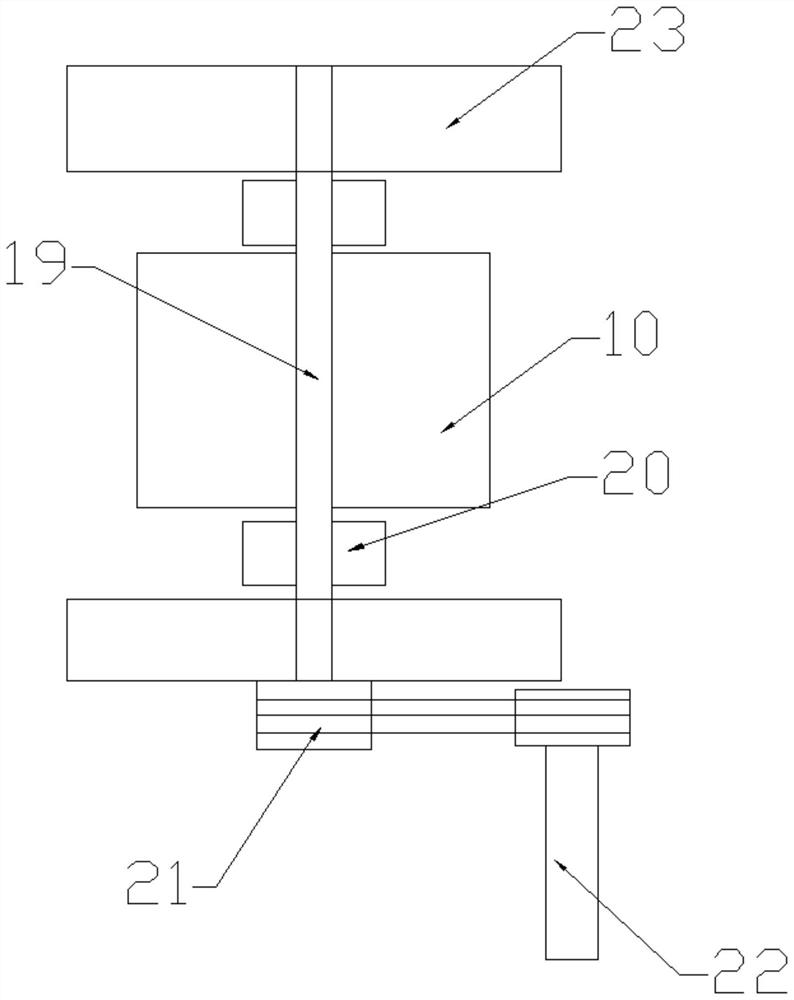

[0026] In conjunction with the accompanying drawings, a water circulation gravity engine utilizing a high-pressure air compression chamber includes a main reservoir 1, a first upright high-pressure air compression chamber 2, and a second upright high-pressure air compression chamber 3. The bottom of the main reservoir 1 is provided with There are parallel high-pressure air compression chambers 4;

[0027] The main reservoir 1, the first upright high-pressure air compression bin 2, and the second upright high-pressure air compression bin 3 are supported by reservoir pillars 5, and between the main reservoir 1 and the parallel high-pressure air compression bin 4 A bottom water circulation high-pressure pipe 6 is provided, a first water circulation high-pressure pipe 7 is provided between the parallel high-pressure air compression chamber 4 and the first vertical high-pressure air compression chamber 2, and the first vertical high-pressure air compression chamber 2 is connected to...

Embodiment 2

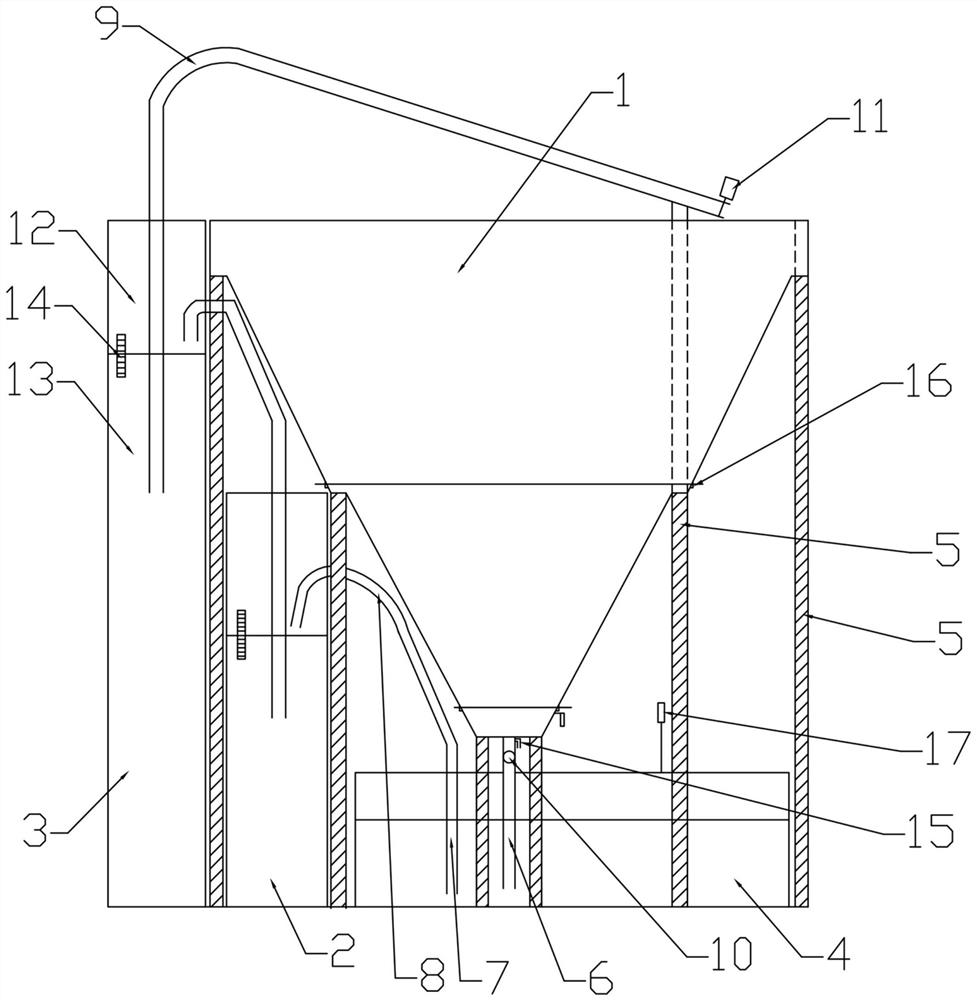

[0037] In conjunction with the accompanying drawings, a water circulation gravity engine utilizing a high-pressure air compression chamber includes a main reservoir 1, a first upright high-pressure air compression chamber 2, and a second upright high-pressure air compression chamber 3. The bottom of the main reservoir 1 is provided with There are parallel high-pressure air compression chambers 4;

[0038] The main reservoir 1, the first upright high-pressure air compression bin 2, and the second upright high-pressure air compression bin 3 are supported by reservoir pillars 5, and between the main reservoir 1 and the parallel high-pressure air compression bin 4 A bottom water circulation high-pressure pipe 6 is provided, a first water circulation high-pressure pipe 7 is provided between the parallel high-pressure air compression chamber 4 and the first vertical high-pressure air compression chamber 2, and the first vertical high-pressure air compression chamber 2 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com