Efficient preparation method of prefabricated flavor conditioning sheep bone concentrated soup-stock

A technology for concentrating broth and mutton bone soup, applied in food science and other directions, can solve the problems of low degree of industrialization, lack of in-depth development of mutton cooked food, and few types, so as to achieve easy dissolution or leaching, shorten cooking time, and improve nutritional flavor. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

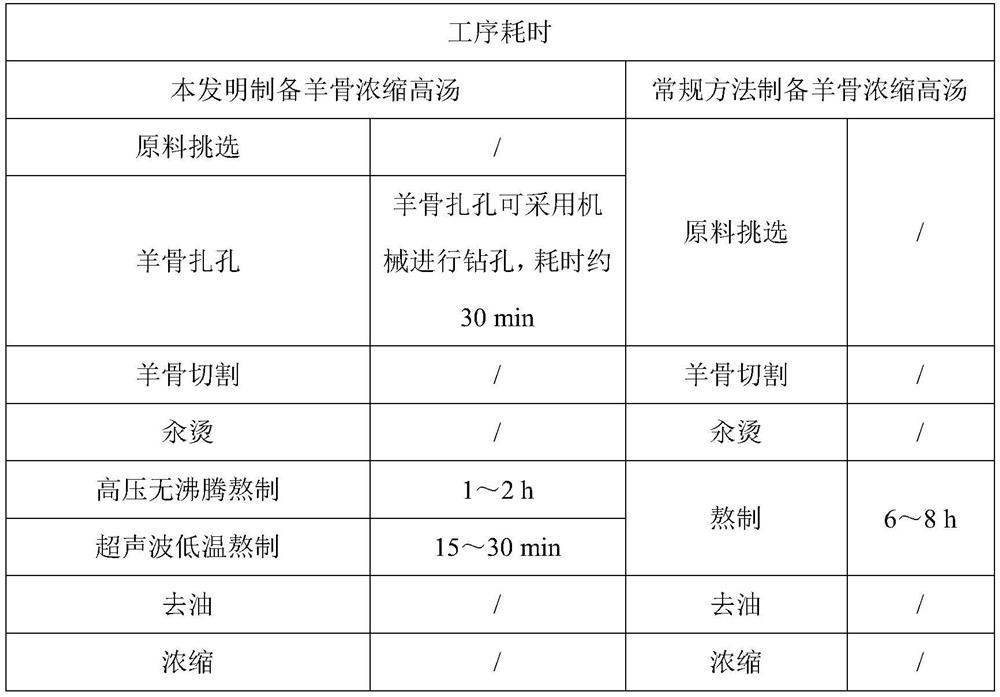

Method used

Image

Examples

Embodiment 1

[0035] A high-efficiency preparation method for prefabricated flavor-conditioned mutton bone concentrated stock, which comprises the following steps:

[0036] (1) Raw material selection: take the sheep stick bone of the age-appropriate goat freshly slaughtered in the slaughterhouse as raw material, wash and set aside;

[0037] (2) Perforation of sheep bone: remove the attached and residual mutton on the surface of the sheep bone, and make micro-holes on the surface of the sheep bone, so that the micro-holes pass through the bone of the sheep bone to reach the marrow cavity;

[0038] (3) Sheep bone cutting: cut the perforated sheep stick bone into a stick shape with a length of 3-6 cm;

[0039] (4) Soaking sheep bones: Soak the cut sheep stick bones in cold water to remove blood and grease foam;

[0040] (5) Blanch: put the soaked lamb bone in boiling water, add sliced ginger and scallion, and scald for 2-4 minutes to remove foam and blood;

[0041] (6) High-pressure non-boil...

Embodiment 2

[0046] A high-efficiency preparation method for prefabricated flavor-conditioned mutton bone concentrated stock, which comprises the following steps:

[0047] (1) Raw material selection: take the sheep stick bones of Guizhou black goats of the right age freshly slaughtered in the slaughterhouse as raw materials, and wash them for later use;

[0048] (2) Hole piercing on sheep bone: Remove the attached and residual mutton on the surface of the sheep bone, and make micro holes on the surface of the sheep bone. 1.2cm, so that the microhole penetrates the bone of the sheep rod bone to reach the bone marrow cavity;

[0049] (3) Sheep bone cutting: cut the perforated sheep stick bone into a stick shape with a length of 3-6 cm;

[0050] (4) Soaking sheep bones: Soak the cut lamb bones in cold water for 1.5-2.5 hours, changing the water every 0.5 hours during this period to remove blood and oil foam;

[0051] (5) Blanch: put the soaked lamb bone in boiling water, add sliced ginger...

Embodiment 3

[0057] A high-efficiency preparation method for prefabricated flavor-conditioned mutton bone concentrated stock, which comprises the following steps:

[0058] (1) Raw material selection: take the sheep stick bones of Guizhou black goats of the right age freshly slaughtered in the slaughterhouse as raw materials, and wash them for later use;

[0059] (2) Pricking holes in the sheep bone: remove the attached and residual mutton on the surface of the sheep bone, and make micro-holes on the surface of the sheep bone. Microholes go through the bone of the sheep rod bone to reach the bone marrow cavity;

[0060] (3) Sheep bone cutting: cut the perforated sheep stick bone into a stick shape with a length of 6 cm;

[0061] (4) Soaking sheep bones: Soak the cut sheep stick bones in cold water for 2 hours, and change the water every 0.5 hours during this period to remove blood and oil foam;

[0062] (5) Blanch: put the soaked lamb bone in boiling water, add sliced ginger and scallio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com