High-strength and high-thermal-conductivity new material solid-liquid composite brake drum and preparation method thereof

A solid-liquid composite, high thermal conductivity technology, applied in the field of auto parts, can solve the problem that the service life of the composite brake drum has not been significantly extended, and achieve good economic and social benefits, excellent thermal conductivity, and improved wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

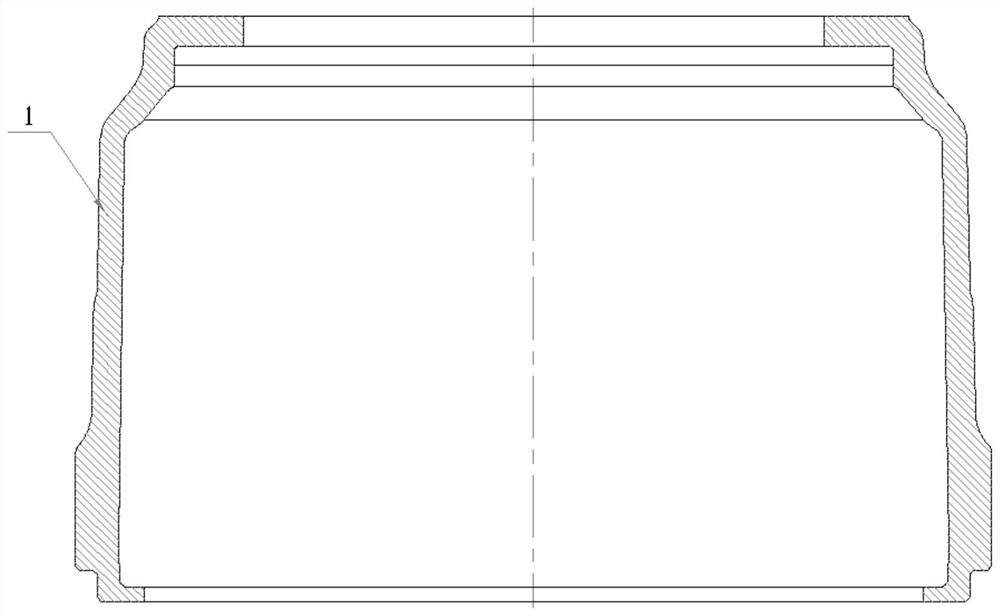

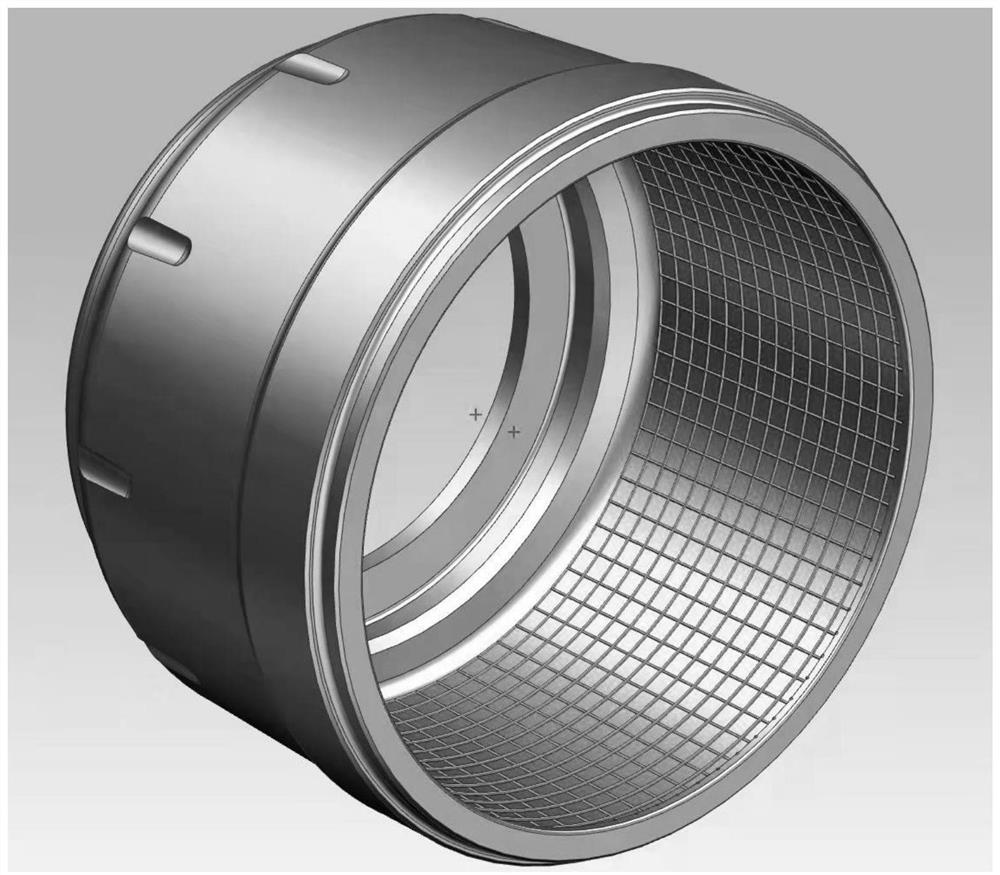

[0034] A high-strength and high-thermal conductivity new material solid-liquid composite brake drum and its preparation method. The outer layer of high-strength ductile iron 1 and the inner layer of high thermal conductivity gray cast iron 2 are integrated by centrifugal solid-liquid composite casting. The specific preparation process steps are as follows:

[0035] ①Smelt nodular cast iron 1 and gray cast iron 2 with medium-frequency induction furnace respectively; first smelt nodular cast iron 1, mix and heat scrap steel, recarburizer, furnace charge and ferrosilicon, and control the chemical composition and mass fraction of molten iron at 3.51% C, 3.11% Si, 0.55% Mn, 0.0003% RE, 0.032% S, 0.037% P, the balance being Fe and unavoidable impurities; when the temperature of the molten iron reaches 1527°C, the molten iron is taken out of the furnace and sent to the spheroidizing ladle;

[0036] ② After all the molten iron enters the spheroidizing ladle, use a top-blowing spray gun...

Embodiment 2

[0042] A high-strength and high-thermal conductivity new material solid-liquid composite brake drum and its preparation method. The outer layer of high-strength ductile iron 1 and the inner layer of high thermal conductivity gray cast iron 2 are integrated by centrifugal solid-liquid composite casting. The specific preparation process steps are as follows:

[0043] ①Smelt nodular cast iron 1 and gray cast iron 2 in an intermediate frequency induction furnace respectively; first smelt nodular cast iron 1, mix and heat scrap steel, recarburizer, furnace charge and ferrosilicon, and control the chemical composition and mass fraction of molten iron at 3.88% C, 2.34% Si, 0.67% Mn, 0.0004% RE, 0.031% S, 0.037% P, the balance being Fe and unavoidable impurities; when the temperature of the molten iron reaches 1544°C, the molten iron is taken out of the furnace and sent to the spheroidizing ladle;

[0044] ② After all the molten iron enters the spheroidizing ladle, use a top-blowing sp...

Embodiment 3

[0050] A high-strength and high-thermal conductivity new material solid-liquid composite brake drum and its preparation method. The outer layer of high-strength ductile iron 1 and the inner layer of high thermal conductivity gray cast iron 2 are integrated by centrifugal solid-liquid composite casting. The specific preparation process steps are as follows:

[0051] ①Smelt nodular cast iron 1 and gray cast iron 2 with medium-frequency induction furnace respectively; first smelt nodular cast iron 1, mix and heat scrap steel, recarburizer, furnace charge and ferrosilicon, and control the chemical composition and mass fraction of molten iron at 3.64% C, 2.88% Si, 0.39% Mn, 0.0037% RE, 0.031% S, 0.036% P, the balance being Fe and unavoidable impurities; when the temperature of the molten iron reaches 1534°C, the molten iron is taken out of the furnace and sent to the spheroidizing ladle;

[0052] ② After all the molten iron enters the spheroidizing ladle, use a top-blowing spray gun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com