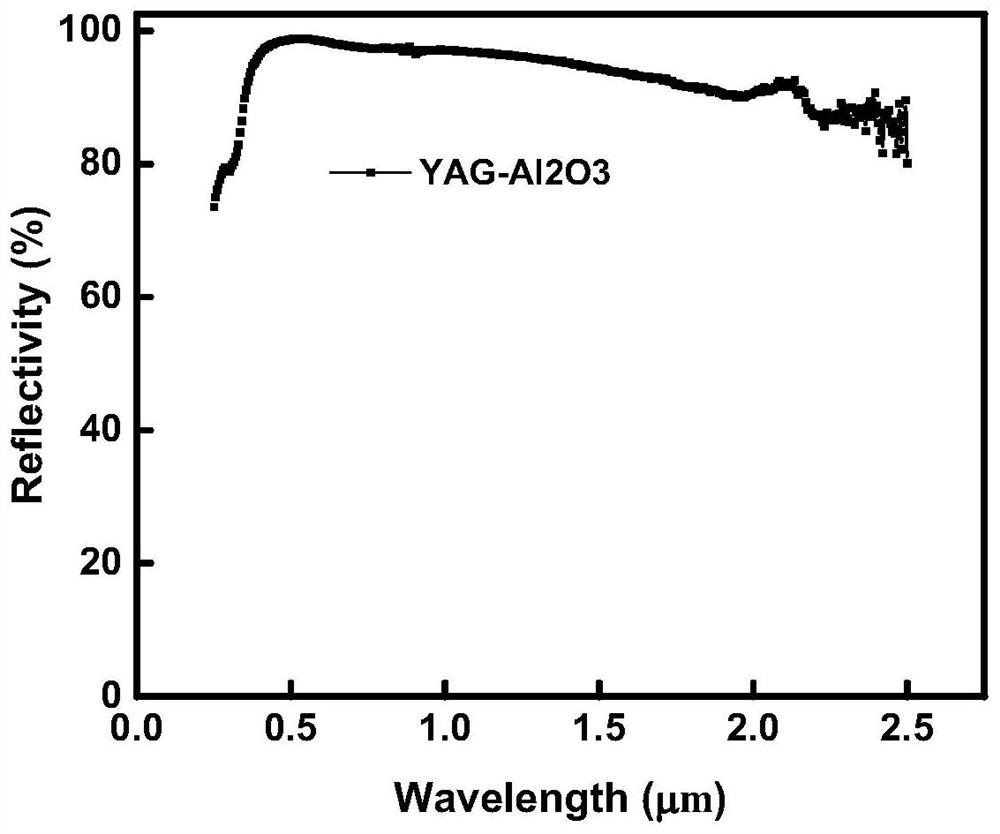

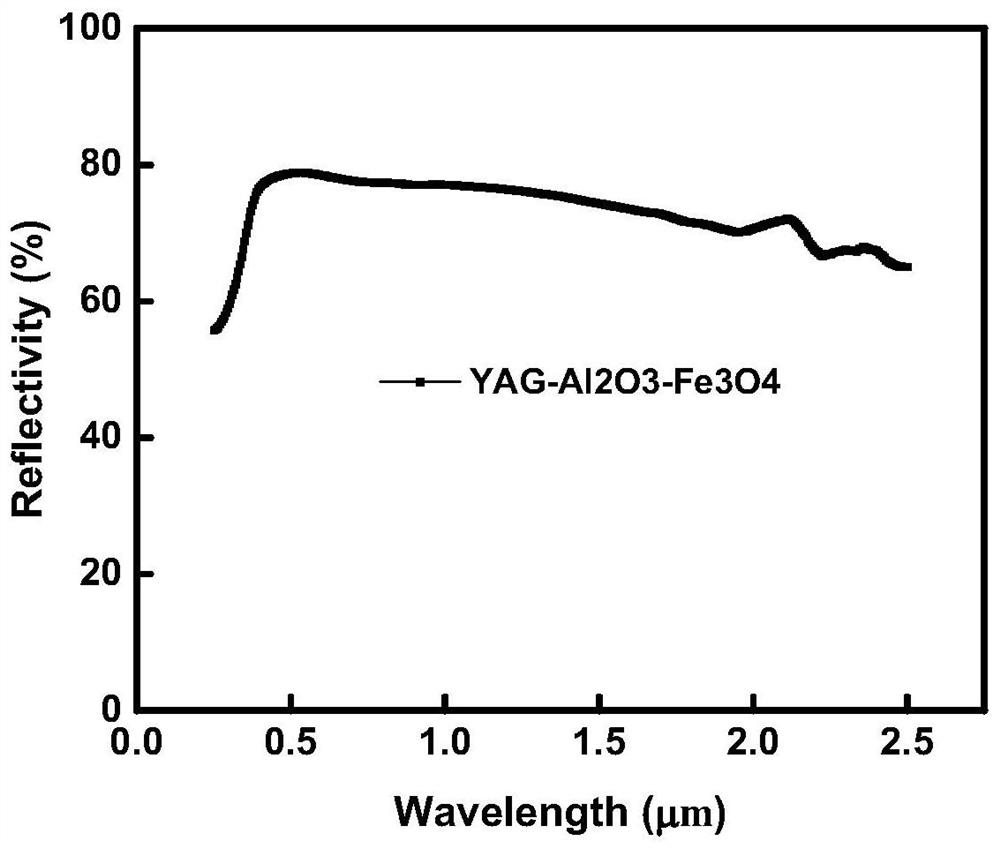

Infrared-radar compatible stealth material based on YAG-aluminum oxide nanofiber membrane as well as preparation method and application of infrared-radar compatible stealth material

A nanofiber and nanofiber layer technology, applied in the field of invisible materials, can solve the problems of poor stability and invisibility, achieve the effects of reducing infrared radiation rate, improving infrared reflection performance, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

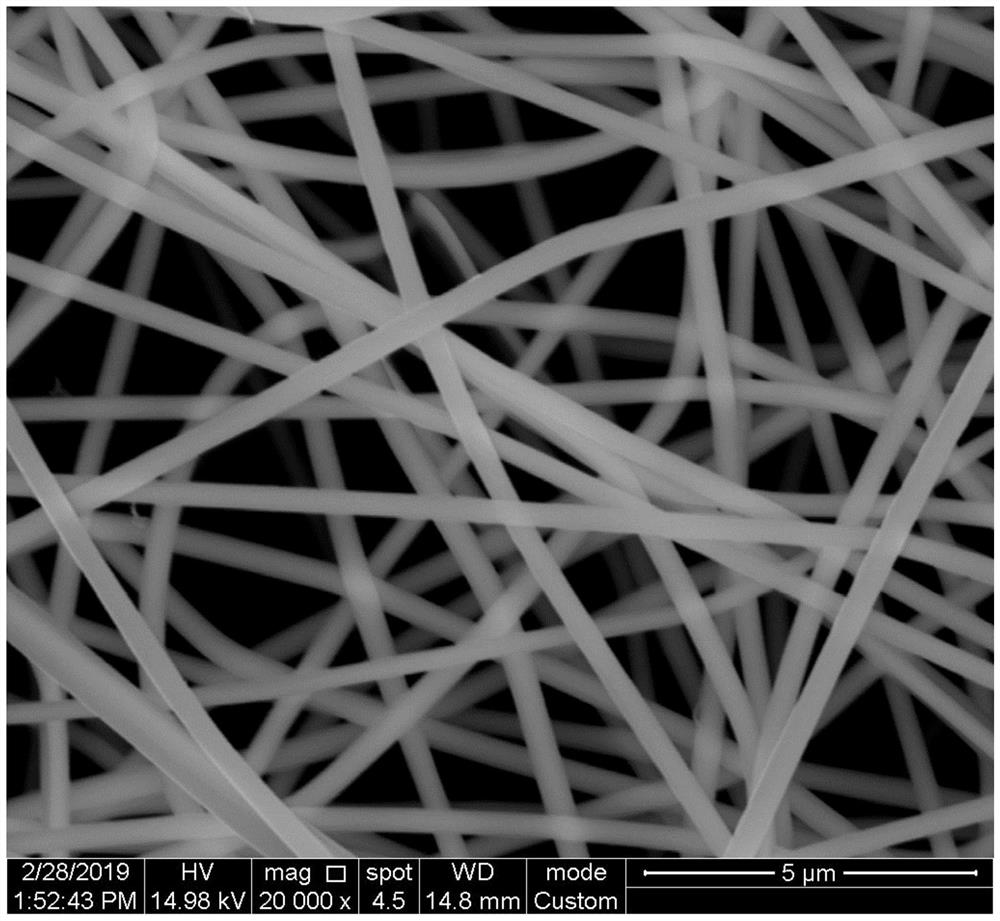

[0031] a kind of Fe 3 o 4 Coated YAG-Al 2 o 3 Nano fiber material, its preparation method comprises the following steps:

[0032] S1: YAG-Al 2 o 3 Preparation of precursor sol:

[0033] Prepare Y(NO 3 ) 3 , YCl 3 Mix the aqueous solution and adjust the pH to 4-5, then add aluminum and aluminum isopropoxide in a molar ratio of (5-8):1 and stir at 90-100°C for 1-5h, mix well to obtain Al 2 o 3 YAG-Al with a content of 10-30wt% 2 o 3 Precursor sol;

[0034] S2: YAG-Al 2 o 3 Preparation of nanofiber layer:

[0035]S2-1: YAG-Al 2 o 3 The precursor sol and the spinning aid are stirred at room temperature for 4-24 hours to make them evenly mixed, and then placed at 60-80°C for 1-2 hours to concentrate to obtain YAG-Al 2 o 3 Precursor spinning solution;

[0036] Wherein, the spinning aid is at least one of PVA, PVP or PEO, and the molecular weight is 8-1.3 million; YAG-Al 2 o 3 The mass ratio of precursor sol and spinning aid is (1-3): 1;

[0037] S2-2: YAG-Al ...

Embodiment 1

[0045] a kind of Fe 3 o 4 Coated YAG-Al 2 o 3 Nano fiber material, its preparation method comprises the following steps:

[0046] S1: YAG-Al 2 o 3 Preparation of precursor sol:

[0047] Y(NO with a molar ratio of 1:2 3 ) 3 ·6H 2 O and YCl 3 ·6H 2 Add O to deionized water, add acetic acid to adjust the pH to 4, then add aluminum powder and aluminum isopropoxide with a molar ratio of 5:1, and stir at 90°C for 1 hour, mix well to obtain Al 2 o 3 10wt% YAG-Al 2 o 3 Precursor sol;

[0048] S2: YAG-Al 2 o 3 Preparation of nanofiber layer:

[0049] S2-1: YAG-Al 2 o 3 The precursor sol and the spinning aid PVA with a molecular weight of 80,000 were stirred at room temperature for 4 hours at a mass ratio of 1:1 to make them evenly mixed, and then placed in a muffle furnace for 1 hour at 60°C for heating pretreatment , to obtain concentrated YAG-Al 2 o 3 Precursor spinning solution;

[0050] S2-2: YAG-Al 2 o 3 The precursor spinning solution is placed in a high-...

Embodiment 2

[0058] a kind of Fe 3 o 4 Coated YAG-Al 2 o 3 Nano fiber material, its preparation method comprises the following steps:

[0059] S1: YAG-Al 2 o 3 Preparation of precursor sol:

[0060] Y(NO with a molar ratio of 1:2 3 ) 3 ·6H 2 O and YCl 3 ·6H 2 Add O to deionized water, add acetic acid to adjust the pH to 4, then add aluminum powder and aluminum isopropoxide at a molar ratio of 5:1, and stir at 95°C for 2 hours to mix evenly to obtain Al 2 o 3 20wt% YAG-Al 2 o 3 Precursor sol;

[0061] S2: YAG-Al 2 o 3 Preparation of nanofiber layer:

[0062] S2-1: YAG-Al 2 o 3 The precursor sol and the spinning aid PVA with a molecular weight of 80,000 were stirred at room temperature for 4 hours at a mass ratio of 2:1 to make them evenly mixed, and then placed in a muffle furnace for 1.5 hours at 70°C for heating Pretreatment to obtain concentrated YAG-Al 2 o 3 Precursor spinning solution;

[0063] S2-2: YAG-Al 2 o 3 The precursor spinning solution is placed in a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com