Residual material removing mechanism for liquid crystal panel

A liquid crystal panel and residual material technology, which is applied in the field of liquid crystal panel automation equipment, can solve problems such as increasing processing time, reducing production takt, and having no residual material, and achieves the effects of reducing fragmentation, improving production efficiency, and protecting fingers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

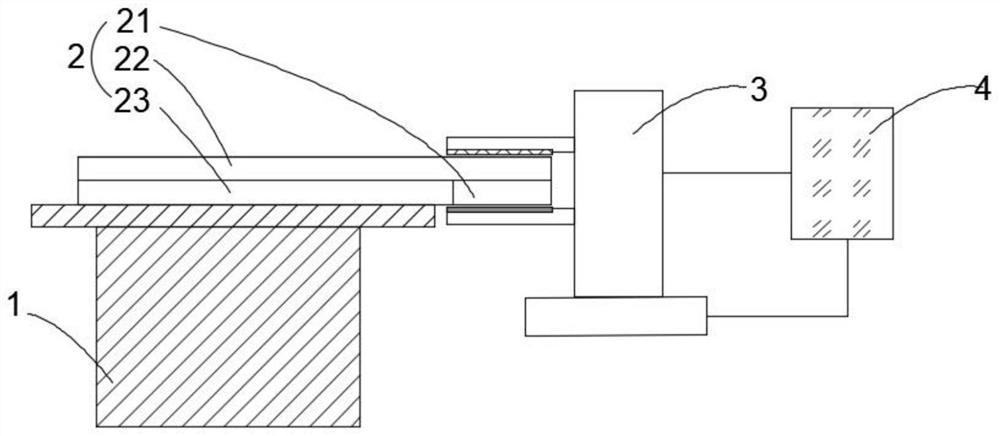

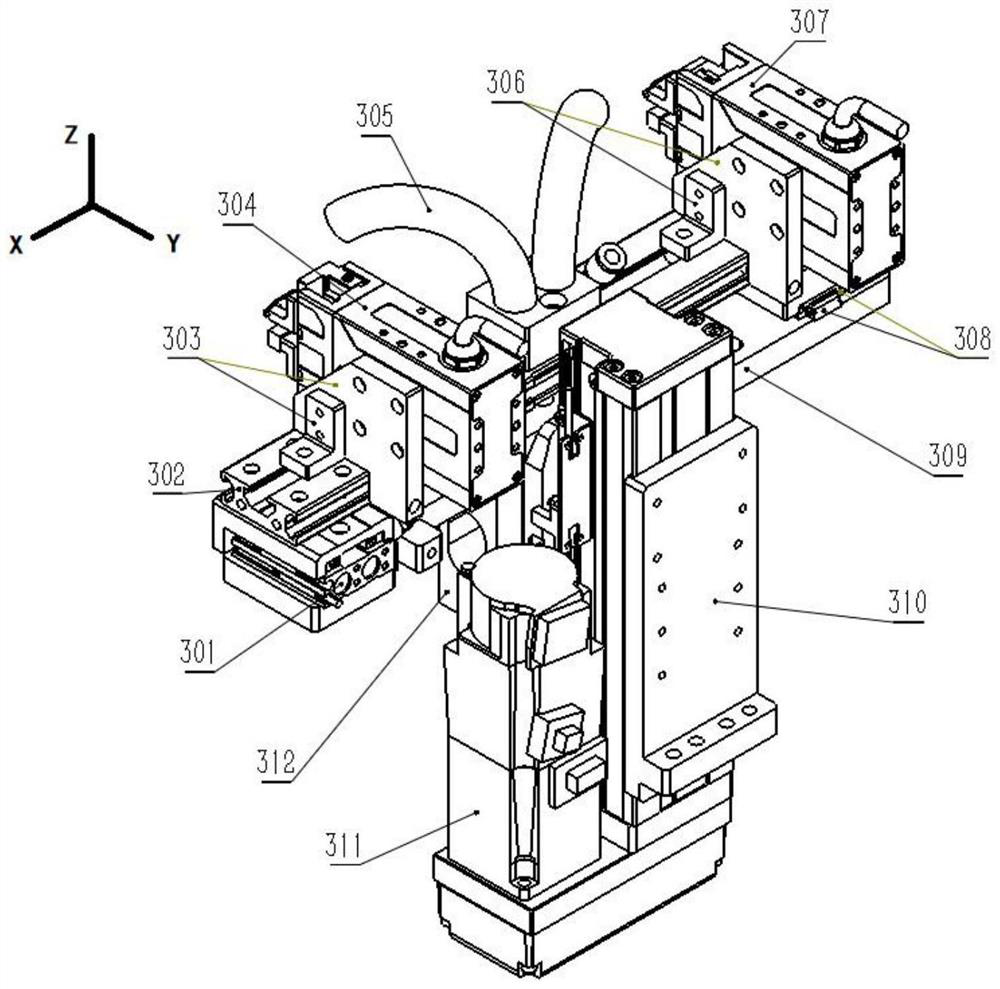

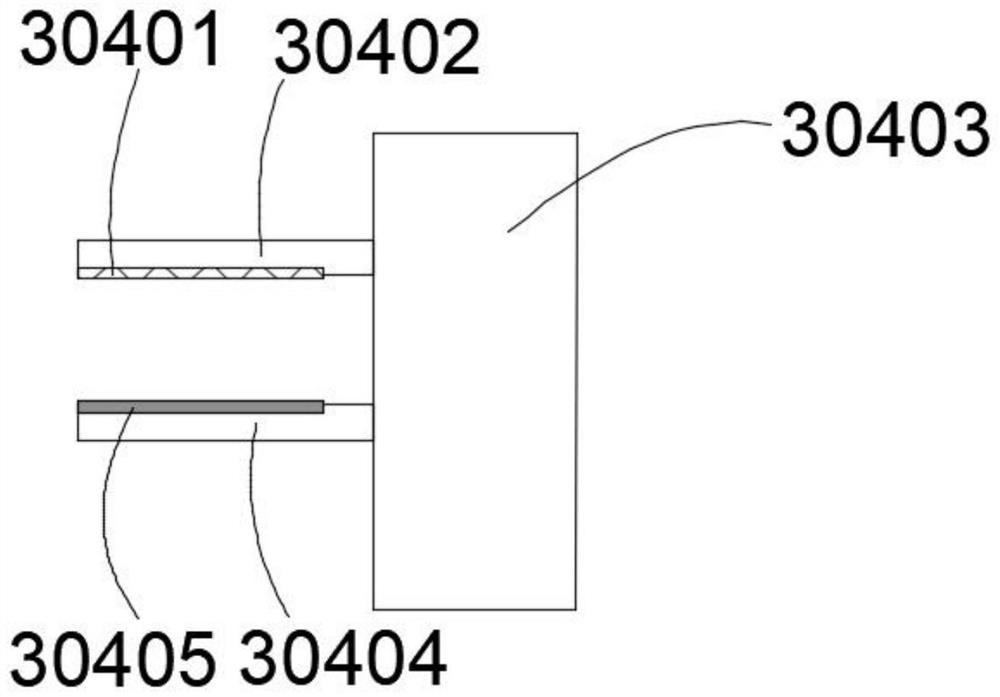

[0020] refer to Figure 1 to 3 , The removal sheave mechanism of a liquid crystal panel includes a stage 1, characterized in that the stage 1 is used to secure the liquid crystal panel 2, the removal sheave assembly 3 drives the jaw assembly A304 from the first module 318 A304 Move in the z-axis direction, the first module 311 is fixed to the machine through the module fixing plate 310, the jaw assembly A304 is fixed to the linker 302 by the first fixed block group 303, the chain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com