Steel and method for manufacturing same

A manufacturing method and billet technology, which can be used in manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of high alloy cost and manufacturing cost, and achieve the effects of excellent low temperature toughness, improved life, and excellent economy.

Pending Publication Date: 2022-04-01

JFE STEEL CORP

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the high cost of alloys and high manufacturing costs, there is an urgent need for steels that are cheap and have excellent toughness at extremely low temperatures

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] Hereinafter, the steel of the present invention will be described in detail.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Login to View More

Abstract

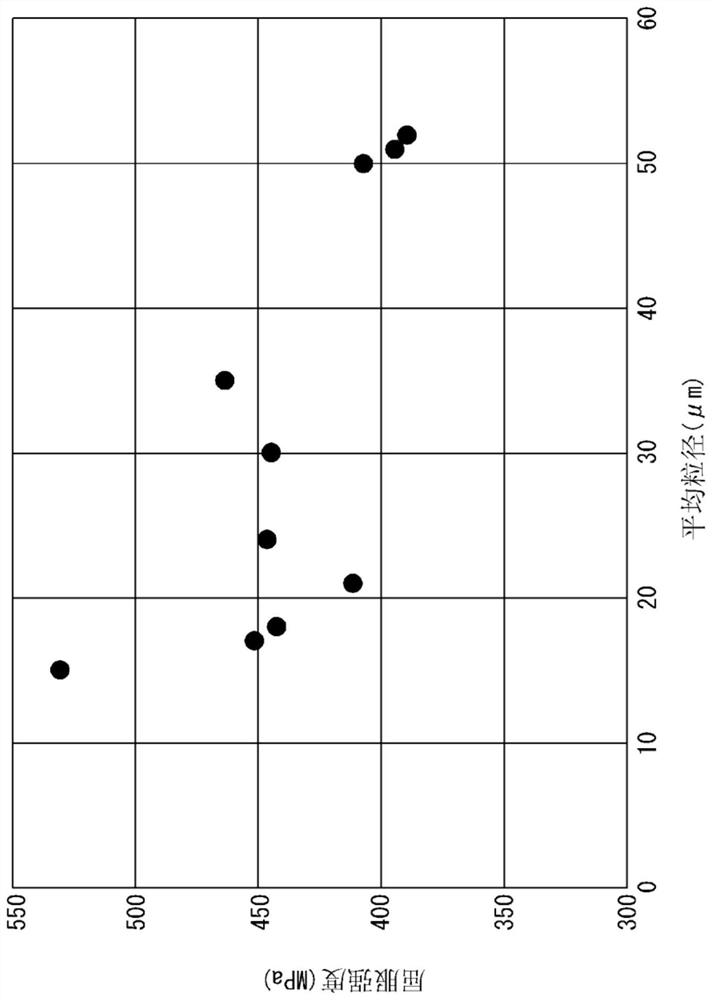

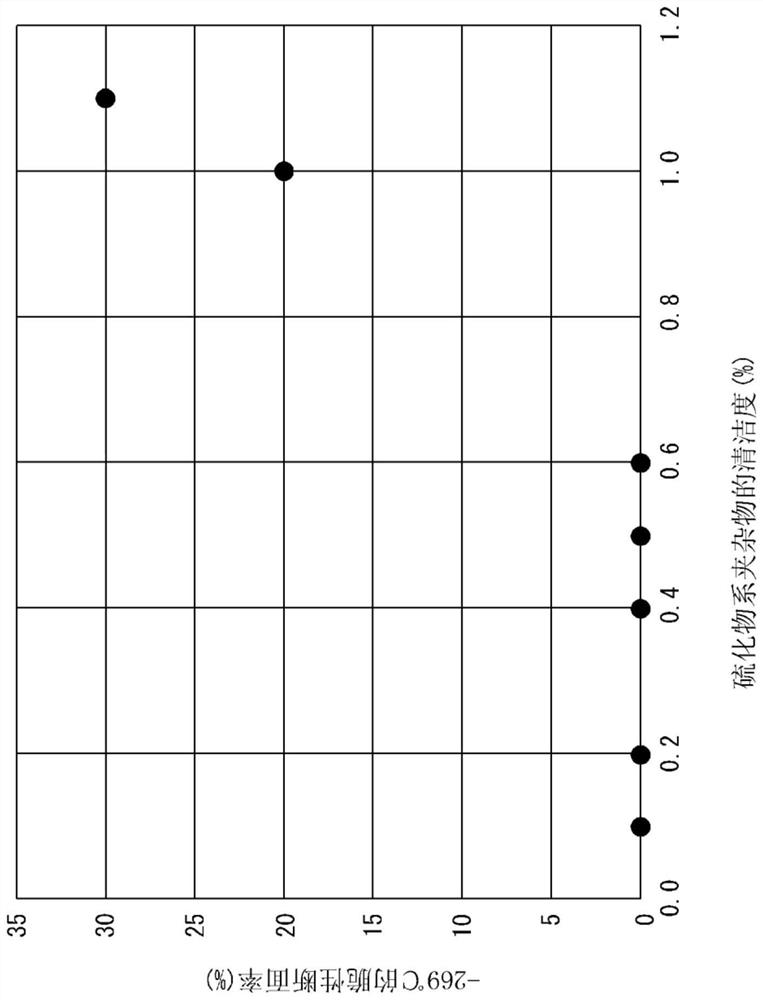

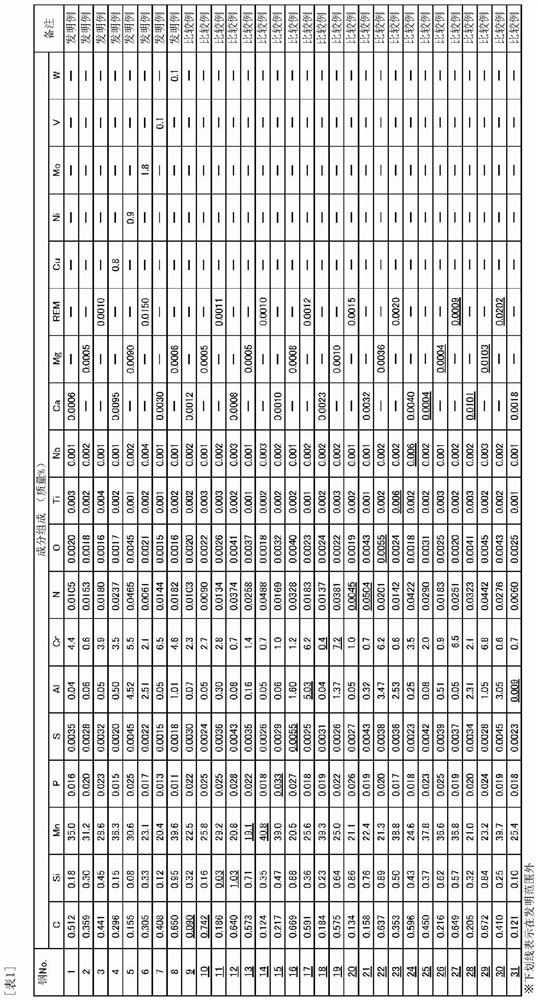

This steel contains, in mass%, 0.100-0.700% of C, 0.05-1.00% of Si, 20.0-40.0% of Mn, less than or equal to 0.030% of P, less than or equal to 0.0050% of S, 0.01-5.00% of Al, 0.5-7.0% of Cr, 0.0050-0.0500% of N, less than or equal to 0.0050% of O, less than or equal to 0.005% of Ti, less than or equal to 0.005% of Nb, and one or more elements selected from the group consisting of 0.0005-0.0100% of Ca, 0.0005-0.0100% of Mg, and 0.0010-0.0200% of REM, and has a microstructure in which austenite serves as a base phase, the average crystal grain size is 50 [mu] m or less, and the cleanliness of sulfide-based inclusions is less than 1.0%. The yield strength is 400 MPa or above, and the brittle section rate after a Charpy impact test at-269 DEG C is less than 5%.

Description

technical field [0001] The present invention relates to steel suitable for structural steel used in extremely low-temperature environments such as liquid helium and liquefied gas, represented by tanks for storing liquid hydrogen, and a method for manufacturing the same. Background technique [0002] When hot-rolled steel sheets are used in liquid hydrogen, liquid helium, and liquefied gas storage tank structures, the steel sheets have high strength and are used in extremely low-temperature environments. Therefore, excellent toughness at extremely low temperatures is also required. For example, when a hot-rolled steel sheet is used for a storage tank of liquid helium, it is necessary to ensure excellent toughness at a temperature of -269° C. or lower, which is the boiling point of helium. If the ultra-low temperature toughness of the steel material deteriorates, the safety as a structure for an ultra-low temperature storage tank may not be maintained. Therefore, it is strongl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C30/02C22C38/02C22C38/06C22C38/20C22C38/22C22C38/24C22C38/26C22C38/28C22C38/38C22C38/42C22C38/44C22C38/46C22C38/48C22C38/50C22C38/58C21D8/02C22C30/00

CPCC22C38/38C22C38/58C21D8/02C22C38/26C22C38/28C22C38/002C22C38/005C22C38/02C22C38/06C22C38/001C22C38/20C22C38/22C22C38/24C22C38/48C22C38/50C21D9/46C21D8/0205C21D8/0226C21D8/0263C21D6/008C21D6/005Y02E60/32C22C38/46C22C38/44C21D2211/001C22C38/04

Inventor 泉大地中岛孝一植田圭治

Owner JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com