Devolatilization and feeding two-in-one device, solution polymerization device and polymerization method

A polymerization device, a two-in-one technology, applied in the direction of feeding device, chemical instrument and method, chemical/physical/physicochemical fixed reactor, etc., can solve high energy consumption, low desolvation efficiency, high polymer color number, etc. problem, to achieve the effect of high manufacturing and maintenance difficulty and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

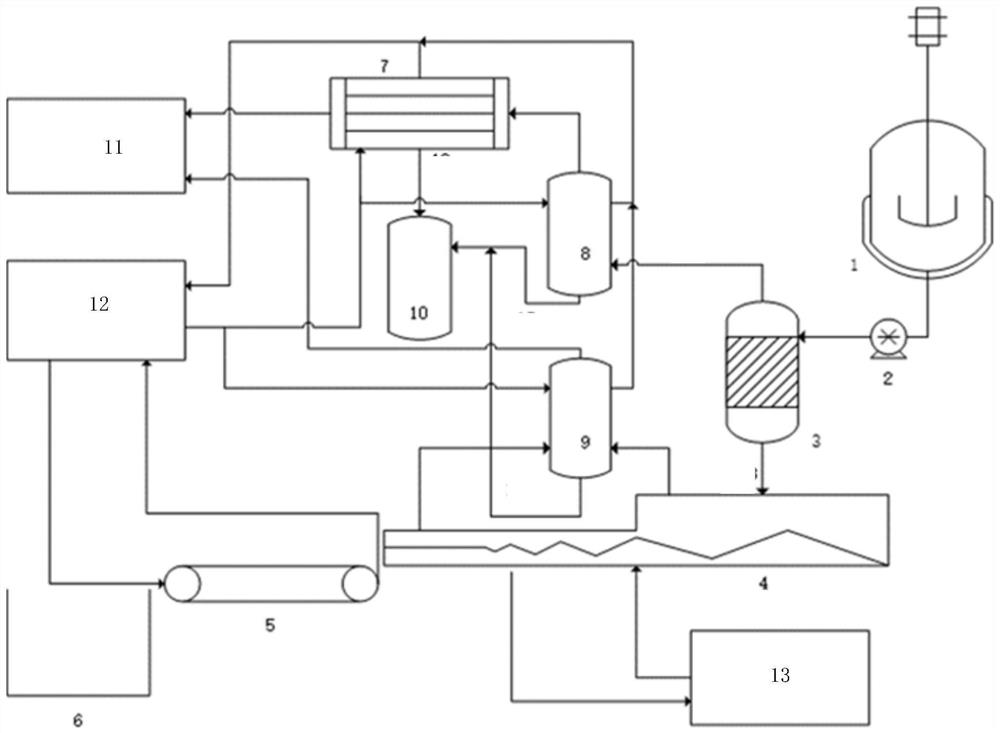

[0153] This embodiment provides a solution polymerization device, the schematic diagram of which is as follows figure 1 As shown, the solution polymerization device includes a reaction system and a solvent removal system;

[0154] Described reaction system comprises reactor 1;

[0155] The solvent removal system includes a first solvent removal system and a second solvent removal system;

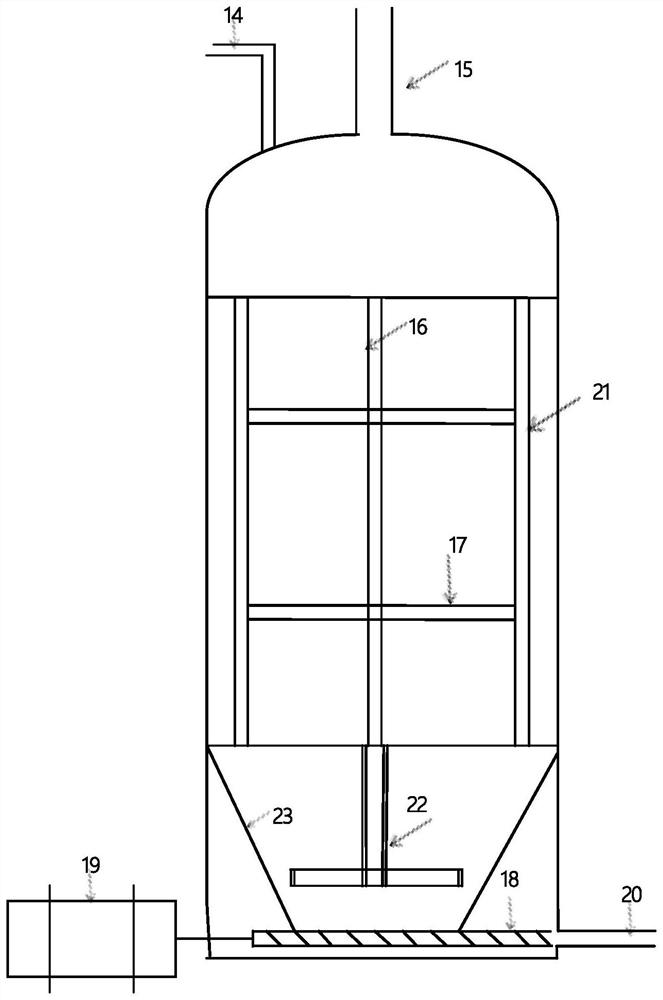

[0156] The first solvent removal system includes a devolatilization feeding two-in-one device 3;

[0157] The second solvent removal system includes a co-rotating twin-screw extruder 4, a first solvent buffer tank 8, a second solvent buffer tank 9, a solvent storage tank 10 and a control system;

[0158] The reaction kettle is connected to the two-in-one device for devolatilization and feeding in the first solvent removal system through a delivery pump 2;

[0159] The control system includes a vacuum system 11, which is a vacuum pump group, a first cooling system 12, a second cooling syst...

Embodiment 2

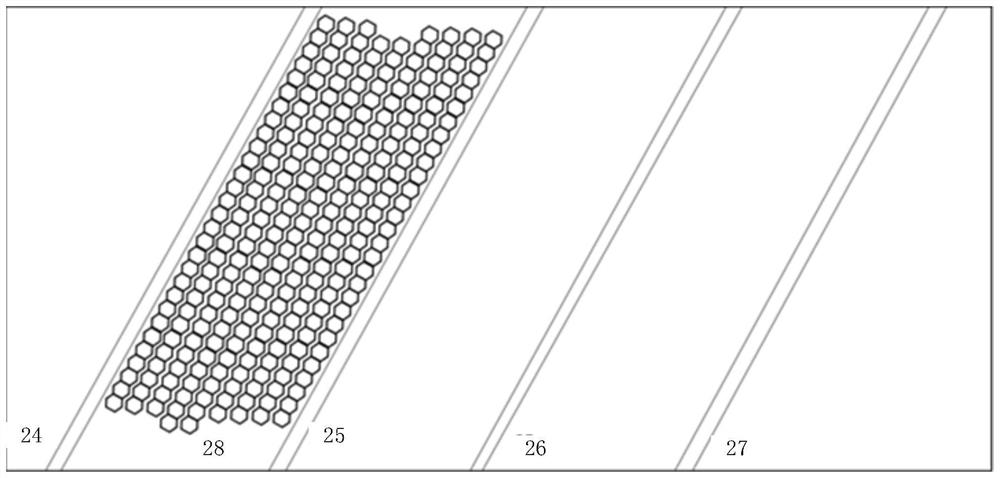

[0168] The difference between this embodiment and Embodiment 1 is that the inner wall surface of the devolatilization and feeding two-in-one device is provided with a hexagonal groove structure 28, and the rotatable surface distribution device includes a first scraping film plate 24, a second The scraper 25, the third scraper 26 and the fourth scraper 27 are arranged parallel to each other, and the included angle with the axial direction is 30°. Shown, all the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com