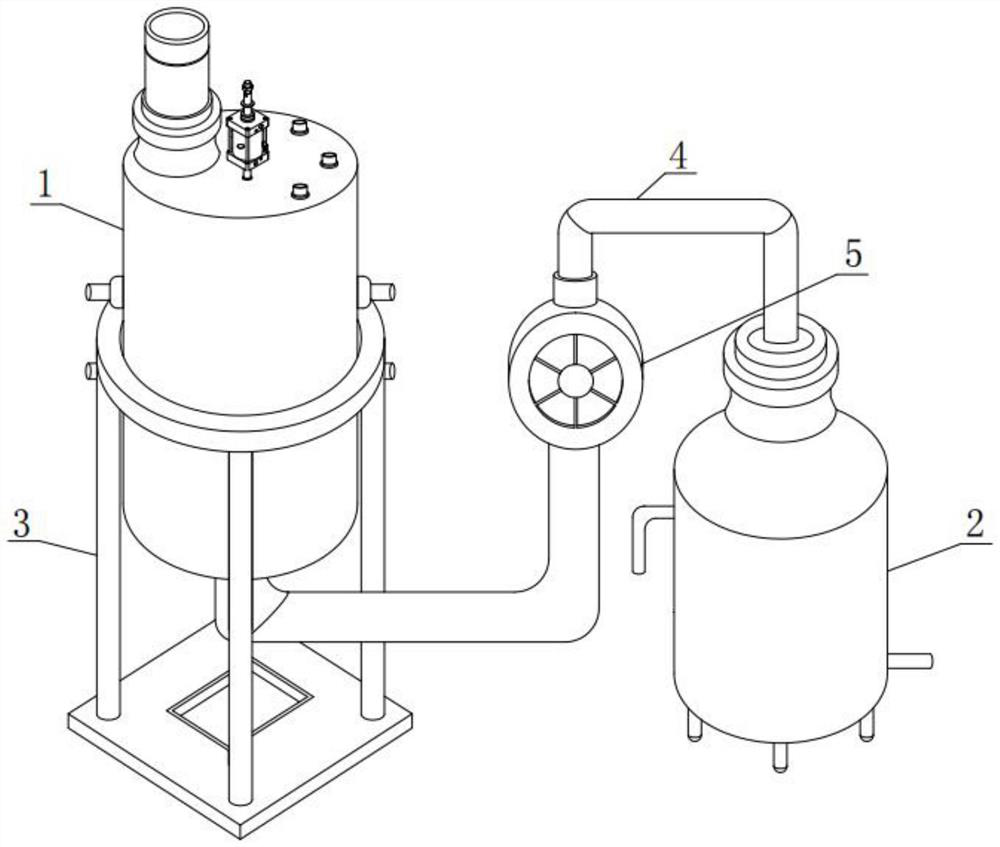

Filtering and impurity removing equipment for conveying high-purity aluminum oxide and implementation method of filtering and impurity removing equipment

A high-purity alumina, filtration and impurity removal technology, which is applied in chemical instruments and methods, filtration circuits, filtration and separation, etc., can solve the problems of impurities in high-purity alumina and the inability of filter devices to filter cleanly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

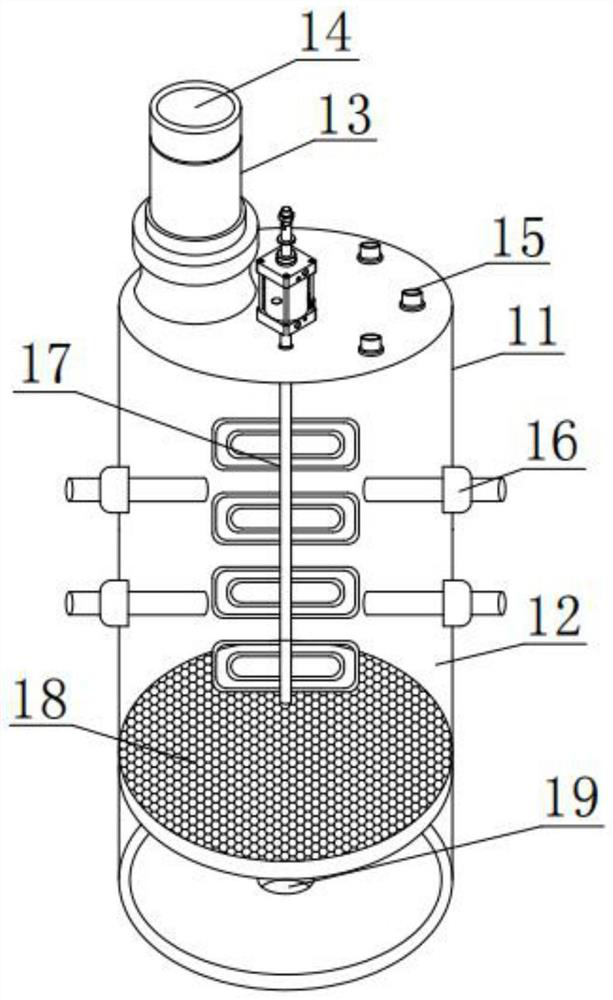

[0048] The implementation method of the filter and impurity removal equipment for high-purity alumina transportation includes the following steps:

[0049] The first step: the material is input from the material inlet 14 opened at the top of the material feeding pipe 13, and the material falls into the first furnace cavity 12, and after the material falls, the stirring device 17 is activated by an external controller;

[0050] Step 2: After the stirring motor 171 is started, it can drive the stirring shaft 172 to rotate, so that the stirring blades 173 provided on the outer wall of the stirring shaft 172 can fully stir and disperse the materials;

[0051] Step 3: After the stirring device 17 fully stirs the material, the material falls from the first filter 18 to the bottom of the first furnace cavity 12, and the material first falls from the steel plate hole 182 to the first filter block 184, and then The first filter block 184 falls into the bottom of the collar 185;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com