Grayscale printing method of thermal printer

A thermal printer and grayscale technology, applied in the temperature recording method, etc., can solve problems such as inaccurate empirical formulas, unsatisfactory grayscale printing effects, etc., and achieve the effect of fine details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In the prior art, the number of heating times required for a grayscale value of 0 to 255 and the proportional coefficient of each heating time are shown in Table 1 below:

[0040] Table 1

[0041]

[0042]

[0043]

[0044]

[0045]

[0046]

[0047]

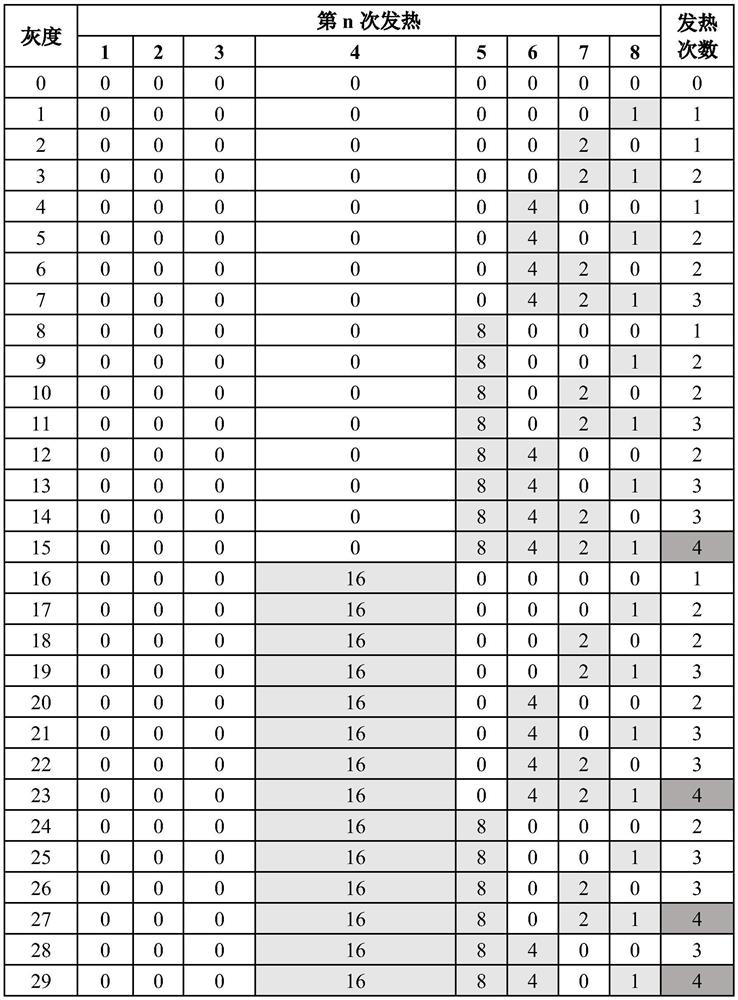

[0048] In the present invention, the number of heating times required for the grayscale value 0 to 31 and the proportional coefficient of each heating time are shown in Table 2 below:

[0049] Table 2

[0050]

[0051]In the process of printing grayscale patterns on thermal printers, it is assumed that a certain grayscale bit Figure 1 There are 8 pixels in the dot row, and their gray values are shown in Table 3.

[0052] table 3

[0053] pixel number 0 1 2 3 4 5 6 7 grayscale value 45 166 95 107 159 0 73 255

[0054] Follow the steps below to print this line in 5-level grayscale:

[0055] Divide the gray value m of each pixel in a row by 2 3 , and then de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com