Pump, washing machine and control method of washing machine

A control method and technology of washing machines, which are applied to the control device of washing machines, other washing machines, washing devices, etc., can solve the problems affecting the installation of other parts of washing machines, unfavorable industrial production of washing machines, and reduced assembly efficiency of washing machines, so as to save the space of the machine body, Improve the use efficiency and reduce the volume of the pump body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

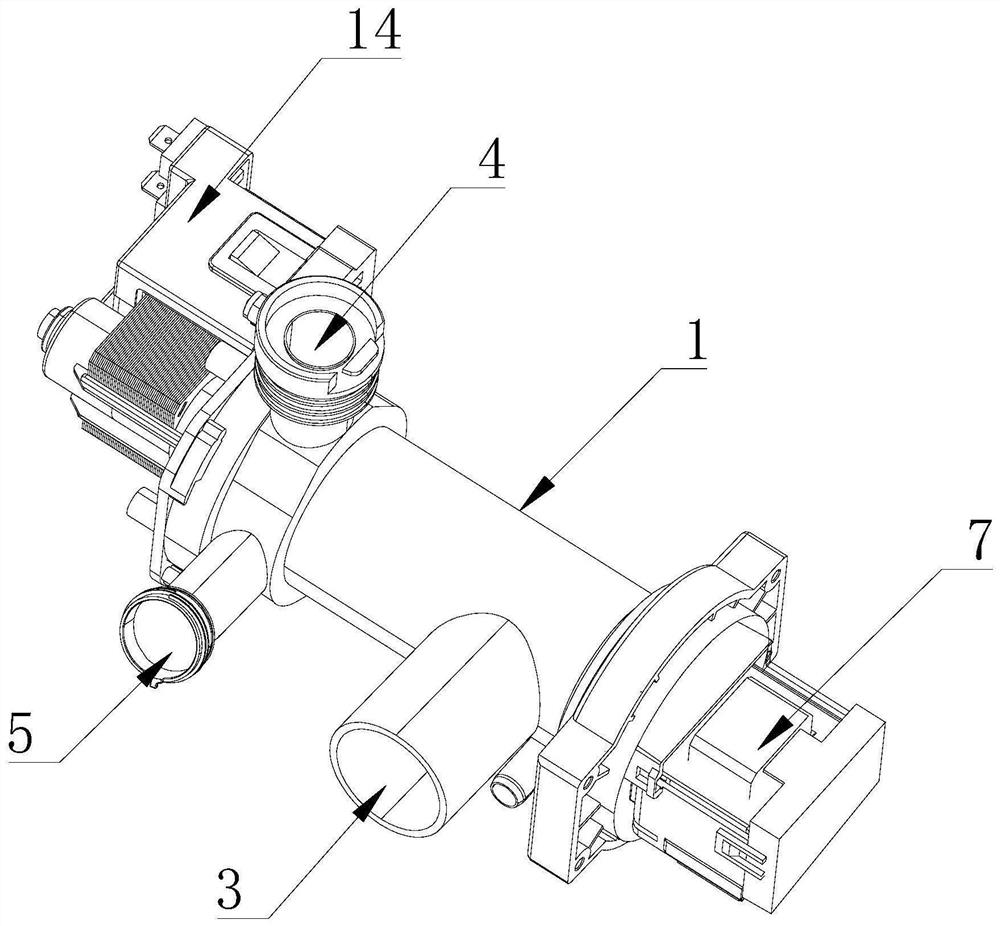

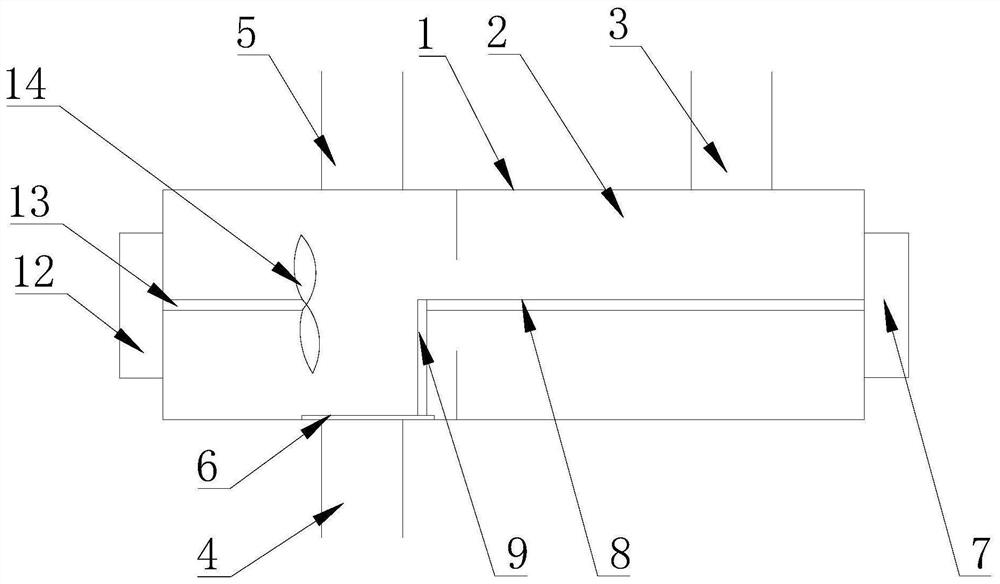

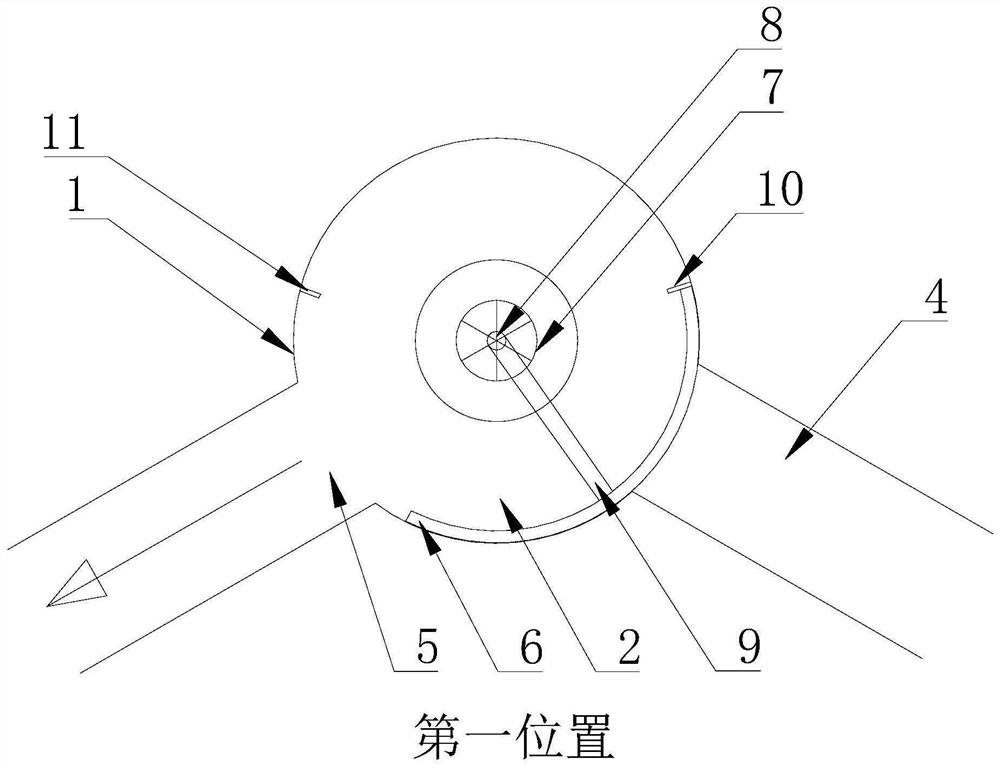

[0037] Such as Figure 1 to Figure 6 As shown, a pump is provided in the embodiment of the present invention, including a pump body 1. The pump body 1 has a hollow chamber to form a pump chamber 2. The pump chamber 2 is provided with a water inlet 3, a drainage outlet 4 and a circulating water outlet 5. , the pump chamber 2 is provided with a valve plate 6 that rotates along the inner wall of the pump chamber 2, and the driving device drives the valve plate 6 to rotate to different positions to open and close the drainage outlet 4 or the circulating water outlet 5 on the corresponding side, so that the valve plate 6 closes the drainage When the outlet is 4, the water inlet 3 communicates with the circulating water outlet 5, or when the valve plate 6 closes the circulating water outlet 5, the water inlet 3 communicates with the drain outlet 4, or the valve plate 6 simultaneously opens at least part of the drain outlet 4 and When the circulating water outlet is 5, the drainage o...

Embodiment 2

[0049] An embodiment of the present invention provides a washing machine, which includes an outer tub containing washing water, a drainage pipeline and a circulation pipeline, one end of the drainage pipeline communicates with the outer tub, and the other end communicates with the drain port; one end of the circulation pipeline communicates with the The outer barrel is connected, and the other end is connected with the circulating water outlet. The washing machine is equipped with a washing machine pump with functions of drainage and circulating water, which saves the space of the washing machine body, facilitates the assembly of other parts of the washing machine, improves the assembly efficiency, reduces the production cost of the washing machine, and is suitable for industrial production.

[0050] In this embodiment, the pump chamber is an annular pump chamber, and the annular pump chamber is provided with drainage outlets and circulating water outlets at intervals along the...

Embodiment 3

[0053] like Figure 3 to Figure 5 As shown, the embodiment of the present invention provides a washing machine control method, which is applied to any of the washing machines described above. During the washing process, the driving device controls the valve plate to rotate to different positions corresponding to the opening and closing of the drainage outlet or the circulating water outlet. .

[0054] In this embodiment, the drive device controls the switch valve plate to rotate to different positions, and then controls the valve plate to close one of the drain outlet and the circulating water outlet or open the drain outlet and the circulating water outlet at the same time, so that the outer barrel and the circulating water outlet The water pipeline is connected, or the outer tub is connected to the drainage pipeline, or the circulating water pipeline is connected to the drainage pipeline, so that the washing water discharged from the outer tub can be recycled or discharged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com