Intelligent contact lens containing flexible circuit and preparation method thereof

A contact lens, flexible circuit technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of affecting function, position and shape are difficult to determine, mechanical modulus mismatch, etc., to reduce demand and improve stretchability , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

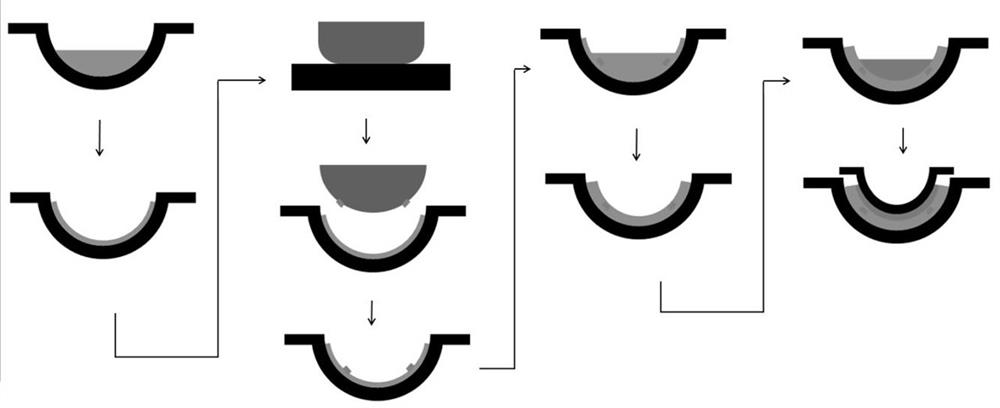

[0025] Such as figure 1 As shown, a smart contact lens containing a flexible circuit includes a first encapsulation layer 1, a flexible circuit 2, a second encapsulation layer 3 and a contact lens layer 4 arranged in sequence, wherein the second encapsulation layer 3 is located at the back of the contact lens layer 4 side of the eye. Wherein, the materials used for the first encapsulation layer 1 and the second encapsulation layer 3 are the same, for example, elastomer materials such as PDMS, Ecoflex, and silica gel.

[0026] In addition to the functions of carrying the flexible circuit 2 and ensuring the structural stability of the flexible circuit, the encapsulation layer also provides water-proof protection for the flexible circuit 2 . It should be understood that figure 1 The structure shown is only a simple schematic diagram of the contact lens structure of the present invention. The actual contact lens layer 4 accounts for most of the thickness of the contact lens, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com