Polylactic resin prepared from various plant materials and preparation method of polylactic resin

A polylactic acid resin and plant material technology, applied in the field of polylactic acid resin, can solve the problems of poor mechanical properties, poor heat resistance, and high production cost, and achieve the effects of improving mechanical properties, increasing heat resistance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

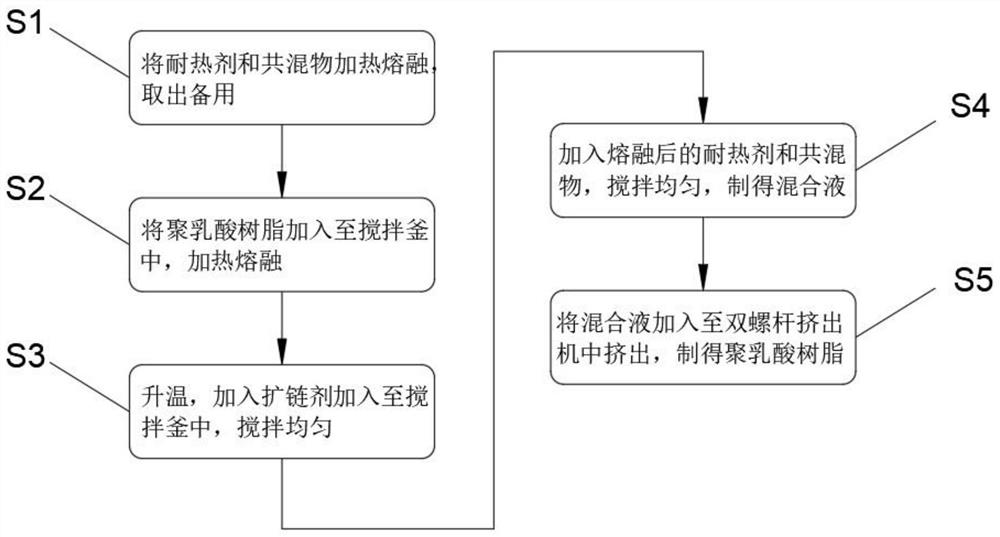

Method used

Image

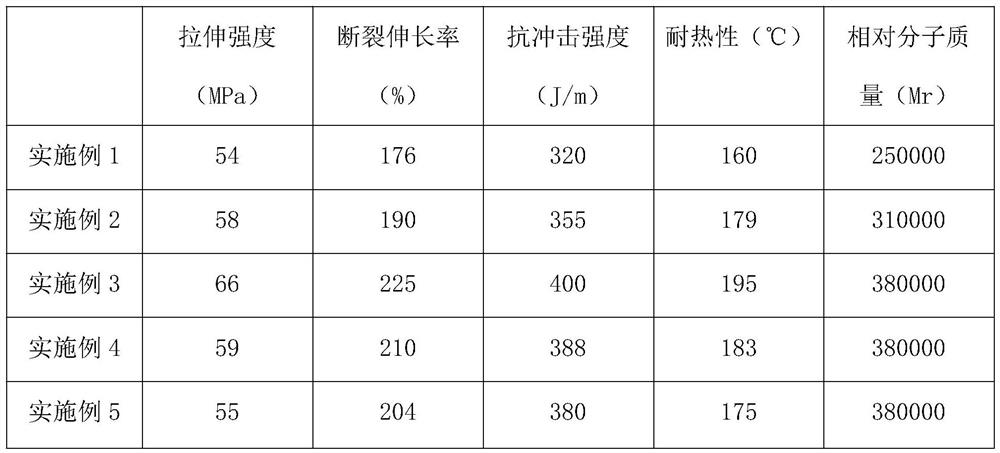

Examples

Embodiment 1

[0042] Embodiment 1 A polylactic acid resin prepared from various plant materials, including:

[0043] 1. Polymer preparation

[0044] (1) Potato starch preparation: wash the potatoes to remove impurities on the surface of the potatoes; grind the cleaned potatoes to obtain a potato paste, sieve and wash the potato paste, and the sieve is potato starch milk, add Put the potato starch into the flow tank, separate the protein and other substances, and then wash to obtain the wet potato starch, dehydrate the wet potato starch, and dry it through a dryer for 4 hours to obtain the potato starch;

[0045] (2) Preparation of cornstarch: clean the corn kernels, soak them in sodium sulfite to soften them, grind the cleaned kernels into corn steep liquor, and precipitate the corn steep liquor. After 4 hours, wet cornstarch is obtained. Wet corn flour is added to the dryer, and after drying for 4 hours, corn starch is obtained;

[0046] (3) Polymer preparation: ferment potato starch and...

Embodiment 2

[0050] Embodiment 2 A polylactic acid resin prepared from various plant materials, including:

[0051] 1. Polymer preparation

[0052] (1) Potato starch preparation: wash the potatoes to remove impurities on the surface of the potatoes; grind the cleaned potatoes to obtain a potato paste, sieve and wash the potato paste, and the sieve is potato starch milk, add Put the potato starch into the flow tank, separate the protein and other substances, and then wash to obtain the wet potato starch, dehydrate the wet potato starch, and dry it through a dryer for 4 hours to obtain the potato starch;

[0053] (2) Preparation of cornstarch: clean the corn kernels, soak them in sodium sulfite to soften them, grind the cleaned kernels into corn steep liquor, and precipitate the corn steep liquor. After 4 hours, wet cornstarch is obtained. Wet corn flour is added to the dryer, and after drying for 4 hours, corn starch is obtained;

[0054](3) Polymer preparation: ferment potato starch and ...

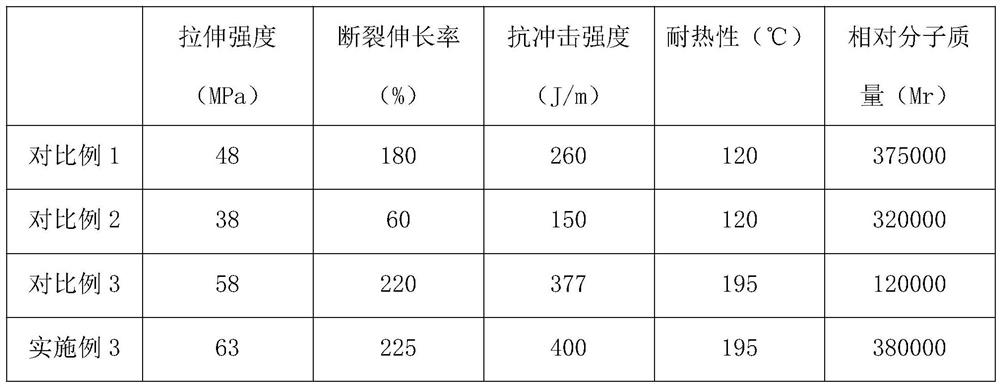

Embodiment 3

[0058] Embodiment 3 A polylactic acid resin prepared from various plant materials, including:

[0059] 1. Polymer preparation

[0060] (1) Potato starch preparation: wash the potatoes to remove impurities on the surface of the potatoes; grind the cleaned potatoes to obtain a potato paste, sieve and wash the potato paste, and the sieve is potato starch milk, add Put the potato starch into the flow tank, separate the protein and other substances, and then wash to obtain the wet potato starch, dehydrate the wet potato starch, and dry it through a dryer for 4 hours to obtain the potato starch;

[0061] (2) Preparation of cornstarch: clean the corn kernels, soak them in sodium sulfite to soften them, grind the cleaned kernels into corn steep liquor, and precipitate the corn steep liquor. After 4 hours, wet cornstarch is obtained. Wet corn flour is added to the dryer, and after drying for 4 hours, corn starch is obtained;

[0062] (3) Polymer preparation: ferment potato starch and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com