Hyperbranched polymer pressure-sensitive adhesive as well as preparation method and application thereof

A polymer, pressure-sensitive adhesive technology, applied in the direction of adhesives, etc., can solve the problems of reduced adhesion performance, rare, limited practical application of adhesives, etc., to achieve the effect of long stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 0.2mol lipoic acid with a tray balance, pentaerythritol tetraacrylate is 5mol% of lipoic acid, polyethylene glycol diacrylate is 15mol% of lipoic acid and agarose is 5wt% of lipoic acid, respectively weigh the above four The components and the three-necked flask are heated to 90° C. and reacted for three hours, and the product is transferred to a tetrafluoroethylene mold for cooling and solidification to obtain a hyperbranched polymer pressure-sensitive adhesive.

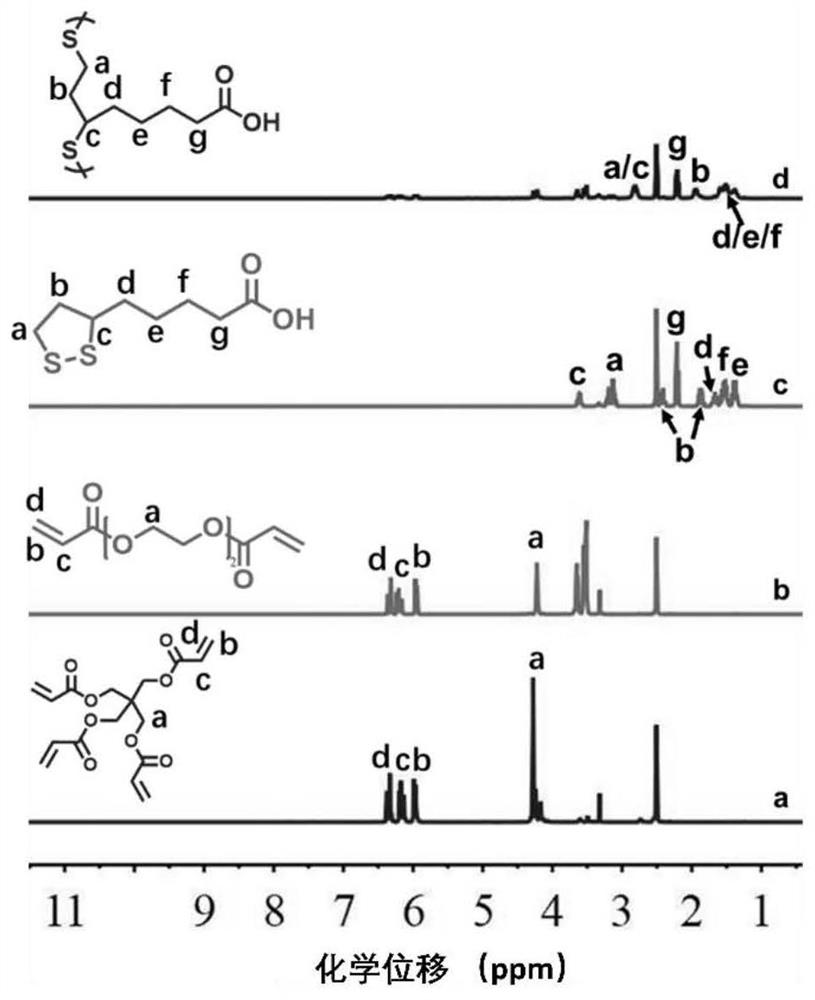

[0028] like figure 1 After the heating reaction, the double bond peak of the multi-double bond monomer disappeared, indicating that the double bond participated in the free radical polymerization and interacted with the thiol radical at the end of the polylipoic acid, while the ring structure in the lipoic acid structure The peaks of 3.58-3.65 and 3.1-3.25ppm shifted to 2.93ppm, indicating that the ring-opening self-polymerization occurred.

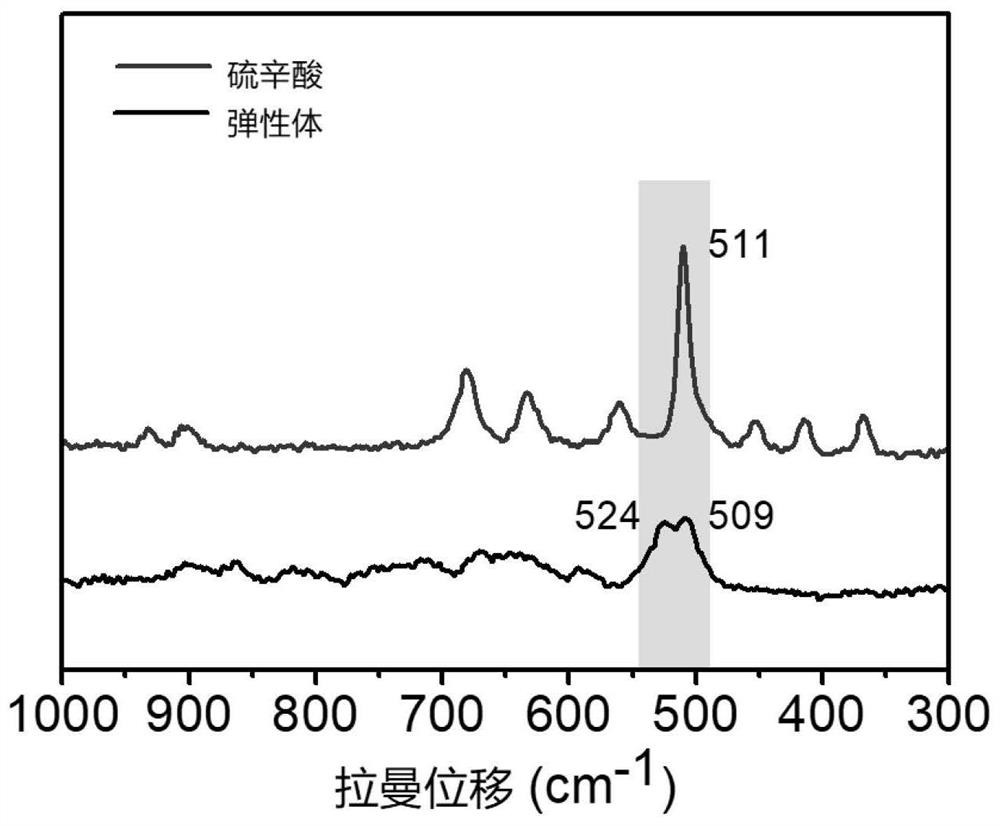

[0029] like figure 2 shown, the lipoic acid monomer at 511...

Embodiment 2

[0041] Take by weighing 0.2mol lipoic acid with a tray balance, the mass sum of pentaerythritol tetraacrylate and polyethylene glycol diacrylate is 1 mol% of lipoic acid (the mol ratio of pentaerythritol tetraacrylate and polyethylene glycol diacrylate is 1: 2), and agarose is 5wt% of lipoic acid, respectively take by weighing above-mentioned four kinds of components and be heated to 80 ℃ in the there-necked flask and react for 4 hours, transfer the product to the tetrafluoroethylene mould and obtain overrun after cooling and solidifying. polymerized pressure-sensitive adhesive.

Embodiment 3

[0043] Take by weighing 0.2mol lipoic acid with a tray balance, the mass sum of pentaerythritol tetraacrylate and polyethylene glycol diacrylate is 2mol% of lipoic acid (the mol ratio of pentaerythritol tetraacrylate and polyethylene glycol diacrylate is 1: 3), and agarose is 5wt% of lipoic acid, take by weighing the above-mentioned four kinds of components and be heated to 95 ℃ in the there-necked flask respectively and react 3 hours after, transfer the product to the tetrafluoroethylene mould and obtain overrun after cooling and solidifying. polymerized pressure-sensitive adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com