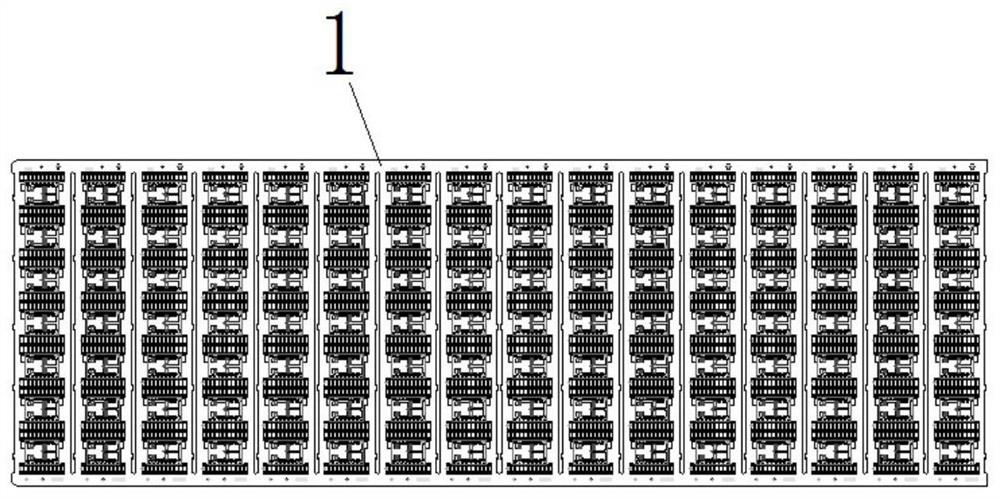

Package with base island isolation frame and substrate chip sealed together and preparation method of package with base island isolation frame and substrate chip sealed together

A packaging and frame technology, applied in the field of integrated circuit packaging applications, to achieve the effect of ensuring product quality and reliability, product quality and reliability assurance, and product quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

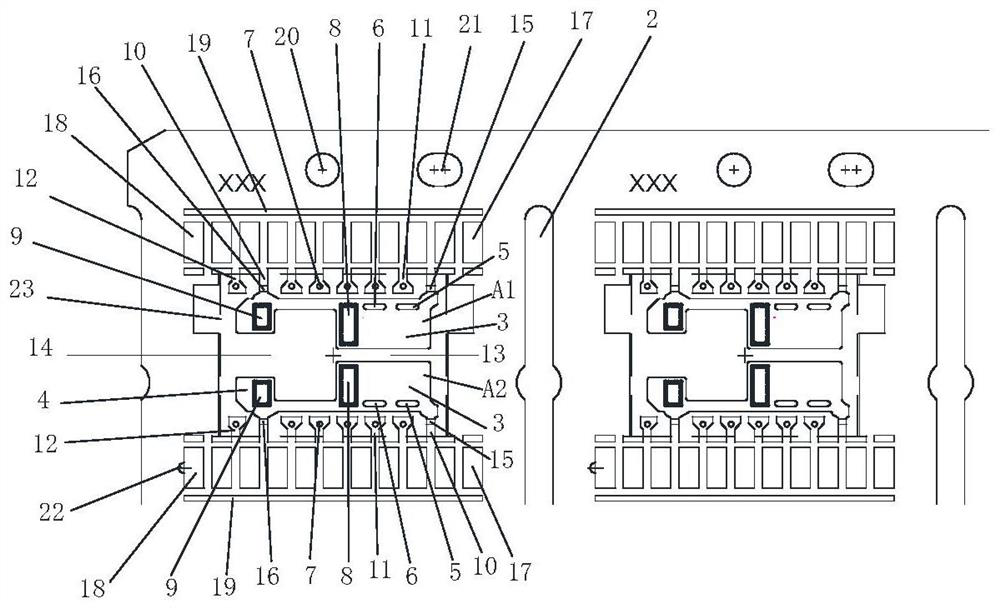

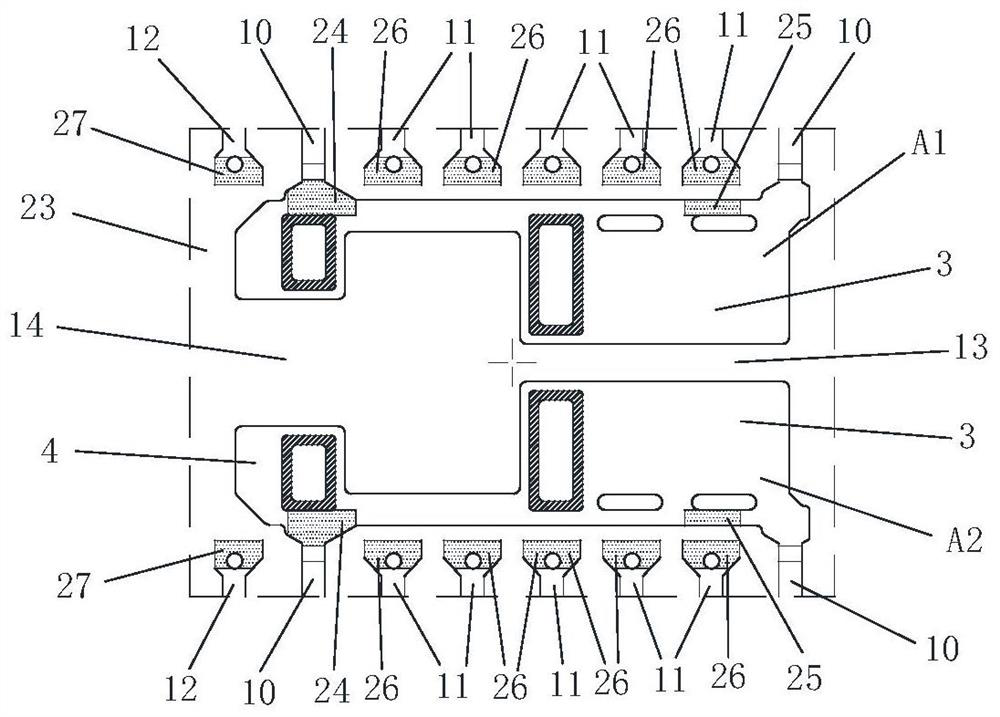

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0043] The package structure of the base island isolation frame and the substrate chip of the present invention is as follows:

[0044] A package in which the base island isolation frame and the substrate chip are sealed together. On the position where the substrate and the isolation chip are bonded on the base island isolation structure frame, an adhesive glue with a thickness of 25 μm to 45 μm is sprayed. The isolation chip is sequentially bonded to the base island isolation structure frame to realize the combination of the substrate, the isolation chip and the base island isolation structure frame, to realize the integrated packaging of the multi-functional module, and to apply the wire bonding technology to make the substrate and the isolation chip through the bonding wire Make electrical connections, and then cover the surface of the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com