Gluing automatic control system

An automatic control system and gluing technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of glue supply pressure fluctuation, product defect rate increase, glue coating speed limitation, etc., to achieve good glue strips, The effect of precise glue output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

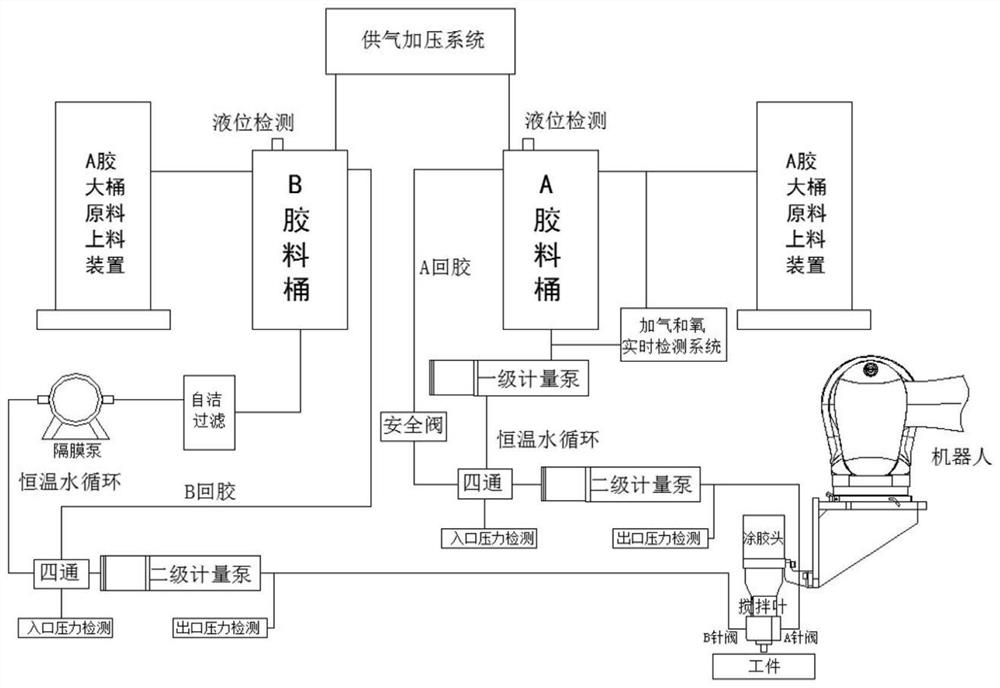

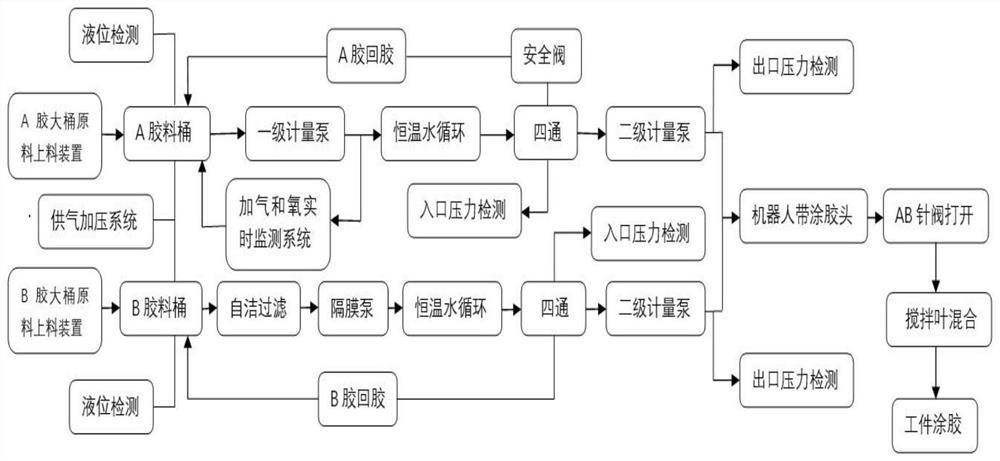

[0020] Such as figure 1 As shown, the present embodiment provides an automatic control system for glue application, including a raw material glue supply system, a glue supply metering system, a six-axis robot (also can be a 6+1 or 6+2 robot) and a PLC industrial computer control cabinet. The PLC industrial computer control cabinet is equipped with parameters such as the amount of glue applied, the trajectory and the ratio of different products.

[0021] The raw material glue supply system includes A rubber raw material vat for holding the rubber material, a B rubber raw material vat for holding the material, A rubber material barrel and B rubber material barrel, and the rubber material in the A glue raw material vat The rubber material in the B rubber material tank is pumped into the A rubber material tank through the raw material feeding device of the A glue vat, and the rubber material in the B rubber material tank is pumped into the B rubber material tank through the B rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com