A kind of high-efficiency milling processing method for veneer particleboard with anti-chipping edge

一种铣削加工、刨花板的技术,应用在饰面刨花板防崩边高效铣削加工领域,能够解决产品不合格率高、板式家具封边处不美观、铣削效率低下等问题,达到提高端部表面质量、避免单板崩边、提高铣削效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

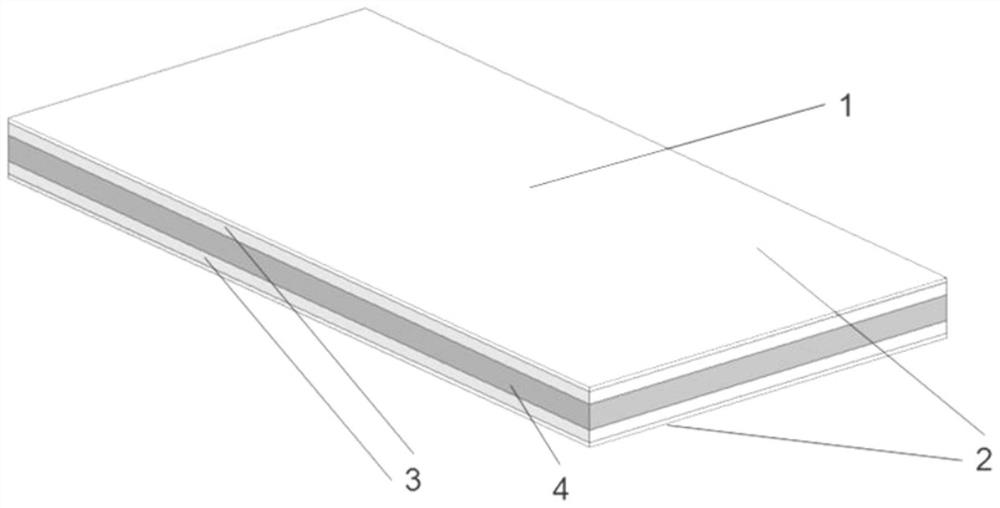

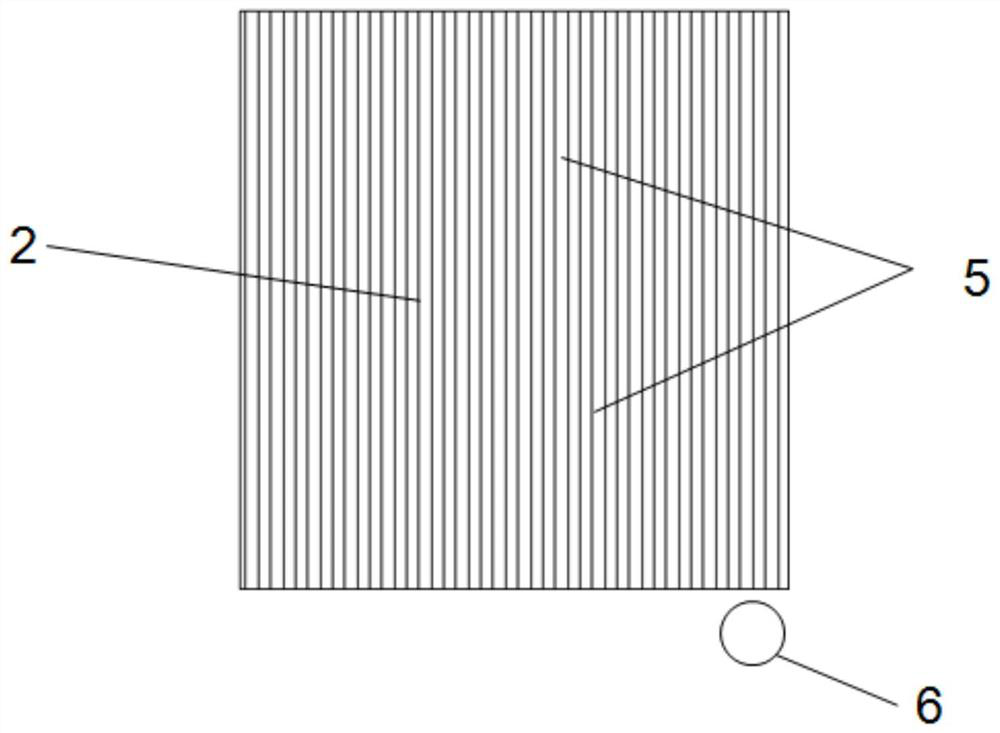

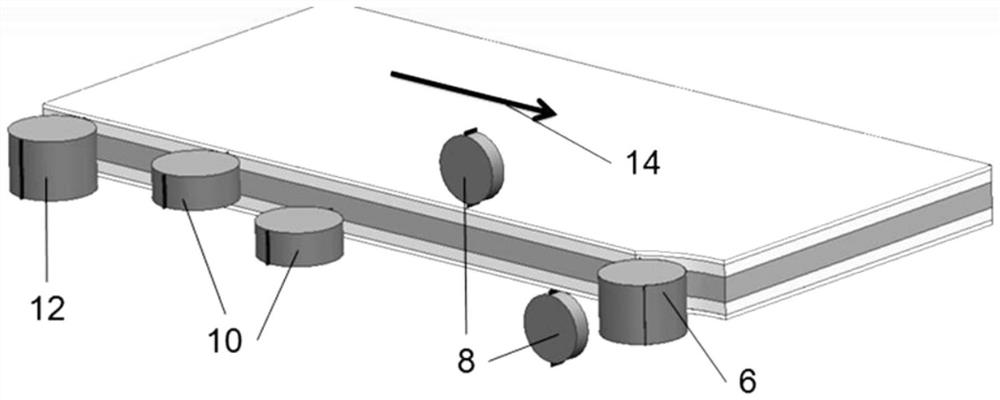

[0030] like Figures 3 to 5 As shown, the embodiment of the present invention provides a technical solution: a high-efficiency milling and processing device for preventing edge collapse of veneer particleboard, the double-end milling is set to 4 stations and 6 cutter shafts, and a corresponding Milling cutters, these milling cutters are: the first milling cutter 6 used for down milling protection at the entrance of the end of the veneer particleboard 1, and the 2 second milling cutters used for the up milling and pre-cutting of the end of the veneer particleboard 1 8. Two third milling cutters 10 for performing up-milling finishing on the end of the veneer particleboard 1 , and a fourth milling cutter 12 for performing down-milling finishing on the entrance of the end of the veneer particleboard 1 .

Embodiment 2

[0032] like Figures 3 to 5 As shown in the figure, the embodiment of the present invention provides a technical solution: a high-efficiency milling method for preventing edge chipping of veneer particleboard. In the double-end milling, climb milling is used to protect the end entry part milling, the end part is pre-cut and milled, and the end part is precisely milled. Repair milling, down milling and finishing milling at the entrance of the end; this method design can reduce the tool axis configuration from 5-station 10-axis or 6-station 12-axis to 4-station 6-axis, which improves the milling efficiency; it also avoids the use of When the milling cutter trims the edge of the veneer veneer particleboard, the veneer edge will collapse, and the particleboard will have burrs and pits, which will cause the problem of unsightly edge sealing of panel furniture and high product failure rate. The tool axis of the double-end milling is configured as 4 stations and 6 tool axes; in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com