Method, device, medium, equipment and instrument for improving refrigerating efficiency of Peltier

A technology of refrigeration efficiency and Peltier element, which is applied in the field of improving Peltier refrigeration efficiency, can solve the problems of low refrigeration efficiency, large air duct volume and difficult arrangement, and achieve the effect of improving refrigeration efficiency and reducing heat dissipation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

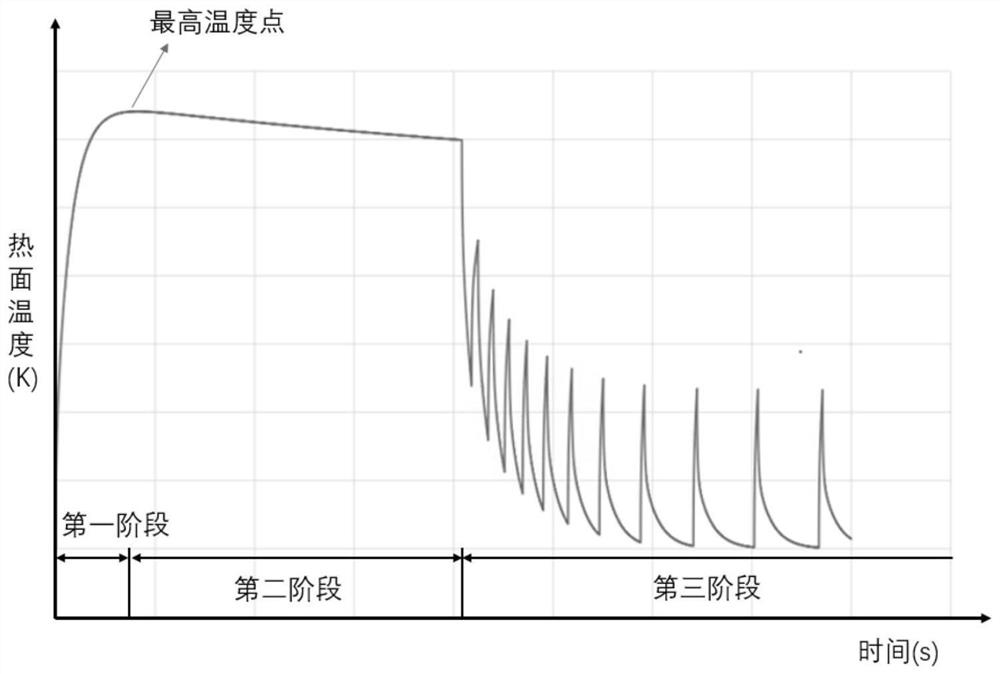

[0064] image 3 A flow chart of a method for improving Peltier refrigeration efficiency is shown. In practical applications, the Peltier element can be a Peltier element in any detection instrument. Such as image 3 As shown, the method for improving Peltier refrigeration efficiency in this embodiment includes steps S310 to S320:

[0065] Step S310, acquiring the temperature of the hot surface and the temperature of the cold surface of the Peltier element in real time.

[0066] Step S320, heating or cooling the hot surface of the Peltier element by controlling the operation or stopping of the Peltier element, so as to control the temperature of the hot surface between the upper limit of the preset temperature and the lower limit of the preset temperature until the temperature of the cold surface reaches target temperature. Wherein, the lower limit of the preset temperature is dynamically adjusted according to the working time and stopping time of the Peltier element in the ...

Embodiment 2

[0094] Figure 8 A block diagram of a device for improving Peltier refrigeration efficiency is shown, such as Figure 8 As shown, this embodiment provides a device 800 for improving Peltier refrigeration efficiency, including:

[0095] Obtaining module 810, for obtaining the hot surface temperature and the cold surface temperature of Peltier element in real time;

[0096] The control module 820 is used to heat up or cool down the hot surface of the Peltier element by controlling the operation or stop of the Peltier element, so as to control the temperature of the hot surface between the upper limit of the preset temperature and the lower limit of the preset temperature until the cold The surface temperature reaches the target temperature;

[0097] Wherein, the lower limit of the preset temperature is dynamically adjusted according to the working time and stopping time of the Peltier element in the previous cycle.

[0098] In practical applications, the control of the operat...

Embodiment 3

[0113] This embodiment provides a storage medium, on which a computer program is stored, and when the computer program is executed by one or more processors, the method in Embodiment 1 is implemented.

[0114] In this embodiment, the storage medium can be realized by any type of volatile or non-volatile storage device or their combination, such as Static Random Access Memory (Static Random Access Memory, SRAM for short), Electrically Erasable and Programmable Electrically Erasable Programmable Read-Only Memory (EEPROM for short), Erasable Programmable Read-Only Memory (EPROM for short), Programmable Read-Only Memory (PROM for short) ), read-only memory (Read-Only Memory, ROM for short), magnetic memory, flash memory, magnetic disk or optical disk. For the details of the method, see Embodiment 1, which will not be repeated this time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com