Pyroelectric infrared sensor

A pyroelectric infrared sensor technology, applied in electrical radiation detectors, instruments, scientific instruments, etc., can solve problems such as stress deformation, reduced detector accuracy, false alarms, etc., to reduce temperature stress and reduce impact. , The effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

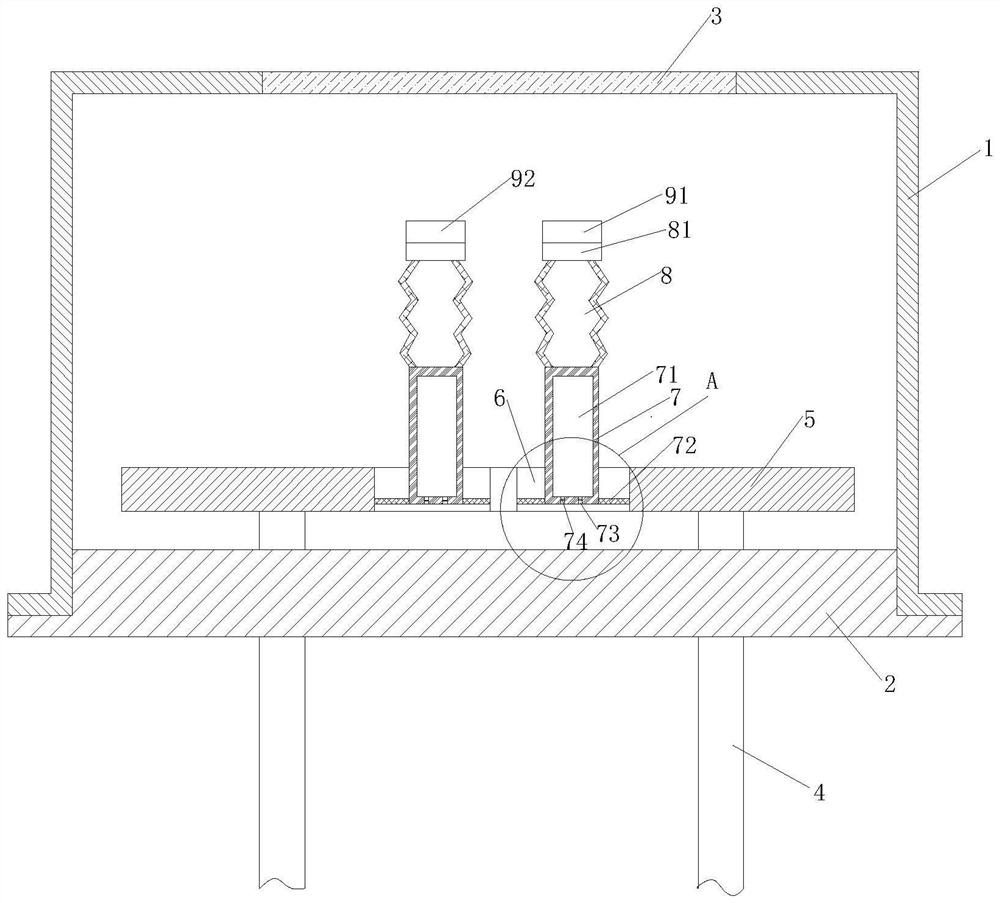

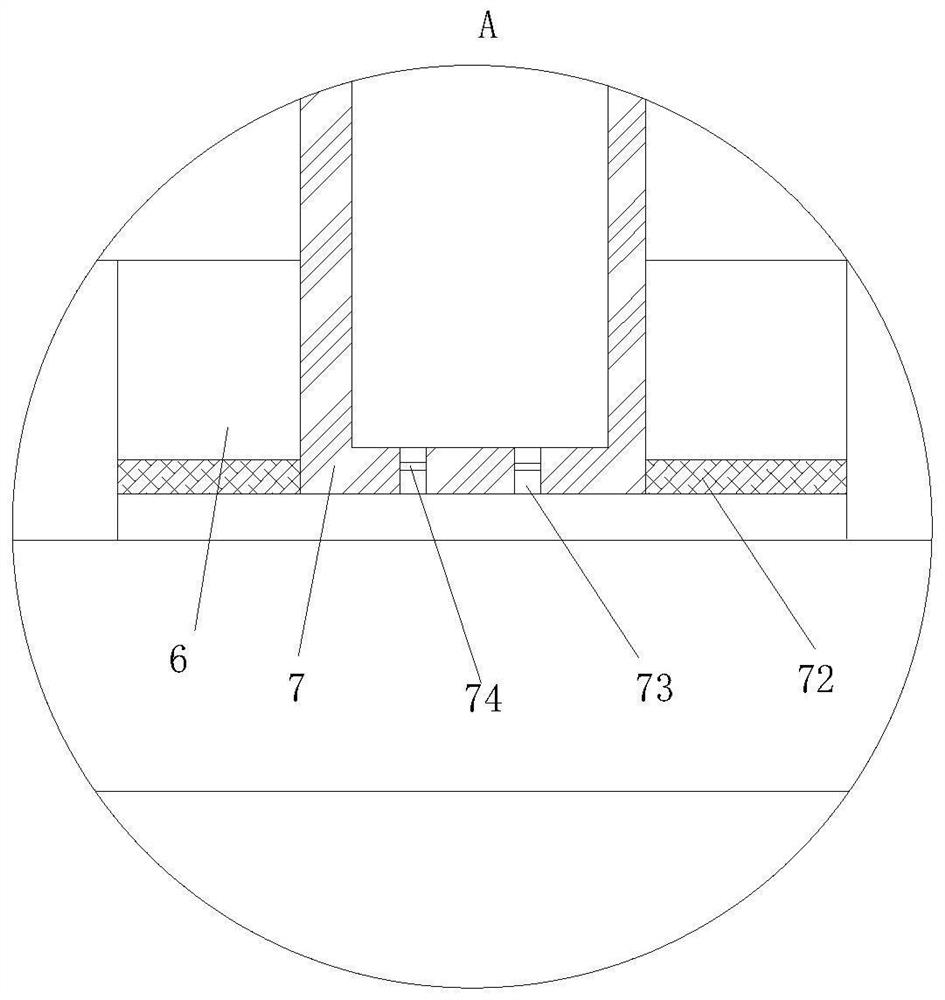

[0023] As a specific embodiment of the present invention, the No. 1 pillar 7 is made of heat-conducting plastic, and is fixedly connected to the inner wall of the through hole 6 through the heat sink 72;

[0024] As the working time of the pyroelectric infrared sensor increases, the heat generated by the printed board 5 continues to increase, and the heat absorbed by the heat-conducting silicone oil is also increasing. Among the present invention, the No. 1 pillar 7 is made of heat-conducting plastic, and the heat-conducting plastic It has the characteristics of uniform heat dissipation, which can better dissipate the heat of the heat-conducting silicone oil; the No. 1 pillar 7 and the heat sink 72 are connected to the inner wall of the through hole 6 in a similar suspended connection mode, and the heat-conducting silicone oil cooperates with the heat sink 72 to make the heat Distributed from the through hole 6, the heat dissipated in the through hole 6 is dissipated to the out...

specific Embodiment approach

[0025] As a specific embodiment of the present invention, the bottom of the No. 1 pillar 7 is provided with more than one cooling hole 73, and the cooling hole 73 is sealed with an oil-proof gas-permeable film 74;

[0026] The heat of the heat-conducting silicone oil can not only be dissipated from the casing of the No. 1 pillar 7, but also can be dissipated through the heat dissipation hole 73 provided at the bottom of the No. 1 pillar 7. Since the heat-conducting silicone oil has fluidity, the heat dissipation hole 73 is sealed with an oil-proof breathable film 74 , can not only dissipate heat and ventilate, reduce the temperature of the heat-conducting silicone oil, but also prevent the heat-conducting silicone oil from leaking out; the heat dissipated by the heat-conducting silicone oil through the cooling holes 73 is dissipated to the outside through the cap 1 and the heat-conducting base 2, reducing the temperature of the pyroelectric infrared sensor The internal heat red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com