Ultrahigh-temperature thermal diffusivity measuring device

A measuring device and diffusivity technology, which is applied in the field of thermal diffusivity measuring devices for ultra-high temperature materials, can solve the problems of low upper limit of thermal diffusivity measurement temperature, and achieve accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

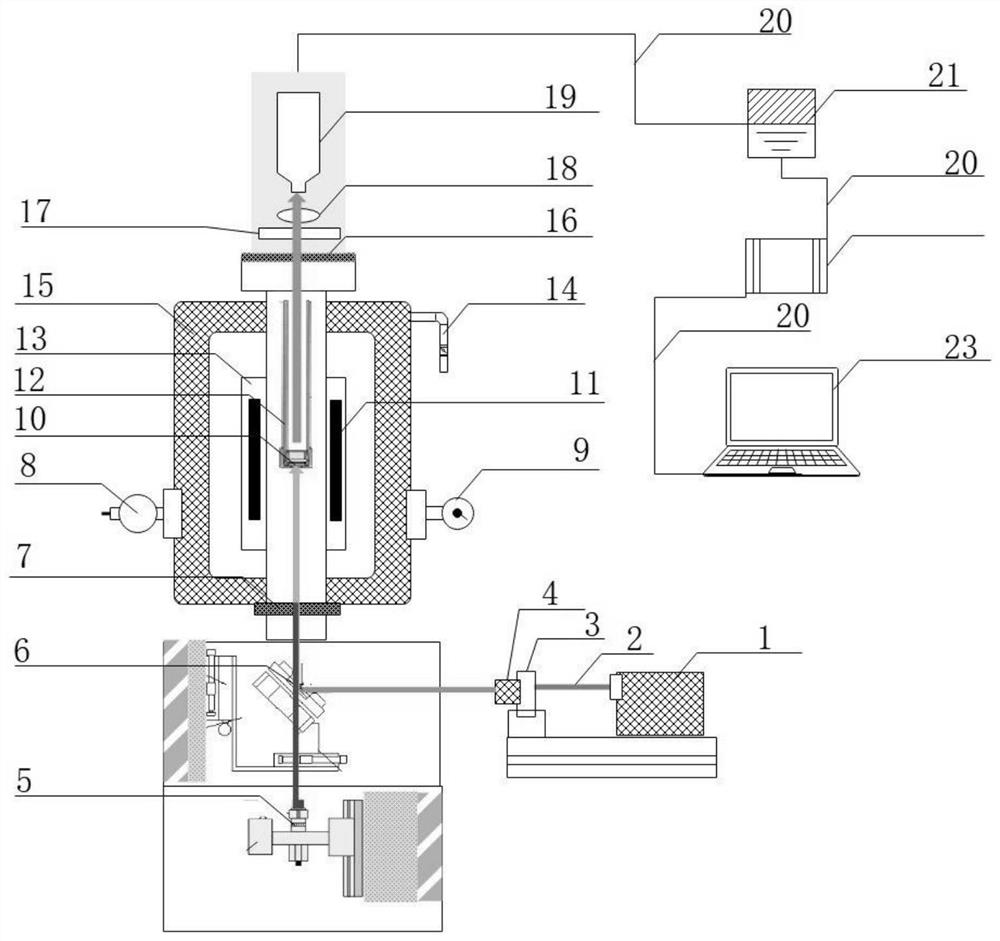

[0025] Such as figure 1 As shown, an ultra-high temperature thermal diffusivity measurement device disclosed in this embodiment includes a pulse excitation system, a high temperature heat source system, a rapid measurement system based on radiation energy and a computer 23, wherein the pulse excitation system is located below the high temperature heat source system, and the pulse excitation system The high-temperature heat source system is isolated from the high-temperature heat source system through the quartz window 7, the radiation energy-based measurement system is located above the high-temperature heat source system, and the radiation energy-based rapid response system is isolated from the high-temperature heat source system through the CaF window 17. The response system based on radiation energy is connected with a computer 23 through 20 .

[0026] The pulse excitation system includes a laser 1, an optical fiber 2, a collimating lens 3, a focusing lens 4, and a mirror 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com