Acoustics-based centrifugal machine rotating speed non-contact measurement method and device

A non-contact, measurement method technology, used in measurement devices, linear/angular velocity measurement, velocity/acceleration/shock measurement, etc., can solve the problems of low accuracy of rotation speed prediction, inaccurate measurement of rotating structures, etc., and achieve response time. Short, maneuverable, high-efficiency measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

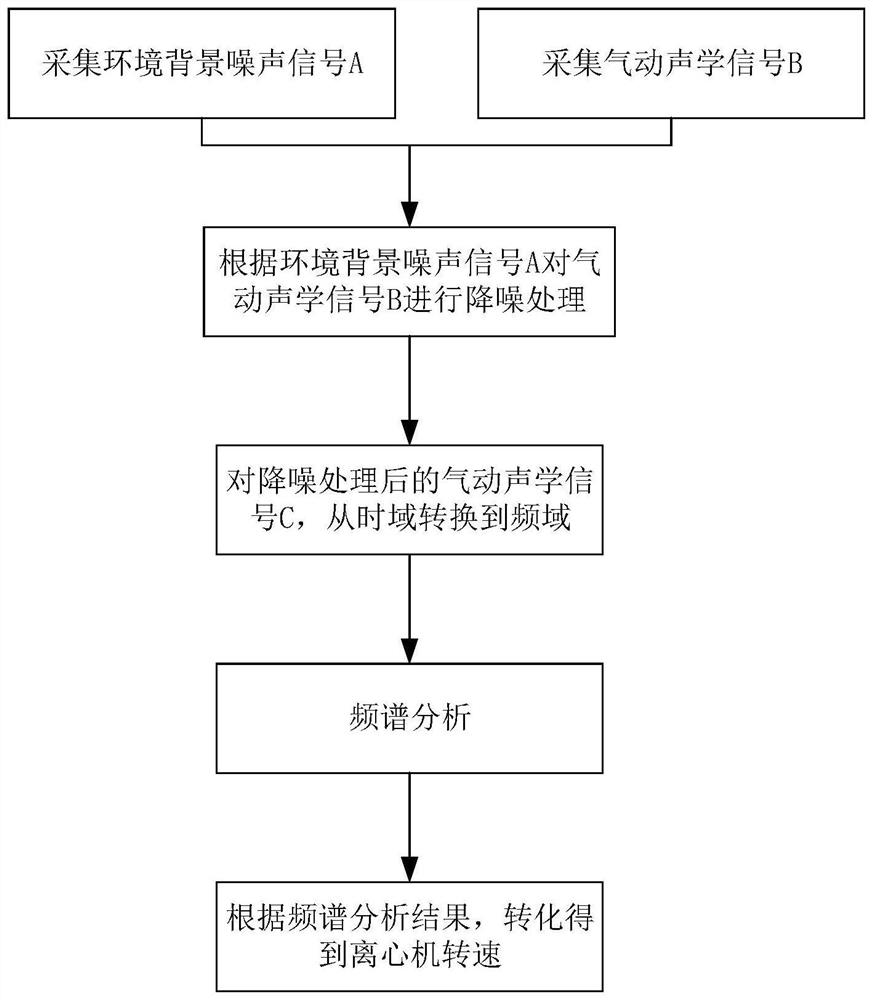

[0038] An acoustic-based non-contact method for measuring the rotational speed of a centrifuge, such as figure 1 shown, including the following steps:

[0039] Place an acoustic signal acquisition system next to the centrifuge;

[0040] When the centrifuge is stopped, the acoustic signal acquisition system is used to collect the acoustic signal to obtain the environmental background noise signal; when the centrifuge is running, the acoustic signal acquisition system is used to collect the acoustic signal to obtain the off-body generated by the airflow around the rotating arm or shaft cutting The aeroacoustic signal of the vortex;

[0041] Perform noise reduction processing on the aeroacoustic signal according to the environmental background noise signal, and convert the aeroacoustic signal after the noise reduction processing to the frequency domain;

[0042] Spectrum analysis is carried out, and the rotational speed of the centrifuge is converted according to the results of...

Embodiment 2

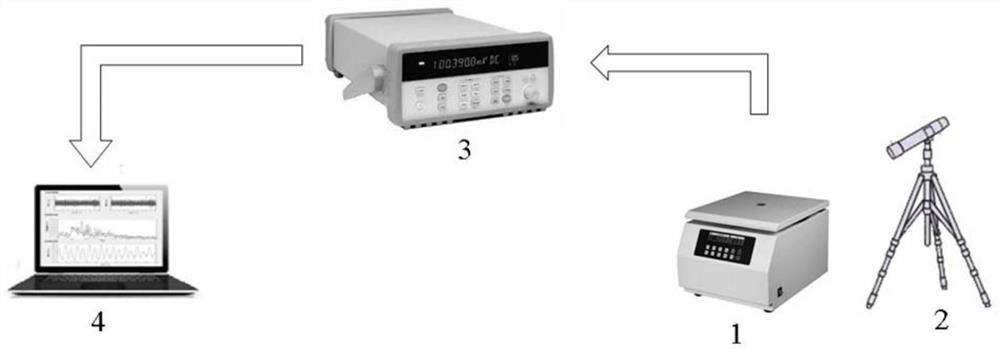

[0051] An acoustic-based non-contact measurement device for centrifuge speed, comprising:

[0052] The acoustic signal acquisition system is arranged next to the centrifuge 1, and is used for acoustic signal acquisition, including the ambient background noise signal when the centrifuge 1 stops and the aerodynamic force of the detached vortex generated by the cutting of the surrounding airflow by the rotating arm or shaft when the centrifuge 1 is running. acoustic signal;

[0053] Among them, the acoustic signal acquisition system includes a non-contact high-precision microphone sensor 2 and a data acquisition card 3, the microphone sensor 2 is arranged at a place 0.2m away from the centrifuge 1, the data acquisition card 3 collects the output signal of the microphone sensor 2, and the acoustic signal acquisition The acoustic signal collected by the system is sent to the data processing system.

[0054] The data processing system is connected with the acoustic signal acquisiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com