Lianren Rolling Centering Test Bench

A technology of test bench and sliding table, which is applied in the direction of machine gear/transmission mechanism testing, etc. It can solve the problem that the axial feed force cannot be detected online, the actual centering accuracy cannot be measured, and the center distance of the centering roller axis cannot be adjusted, etc. problem, to achieve the effect of non-contact high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

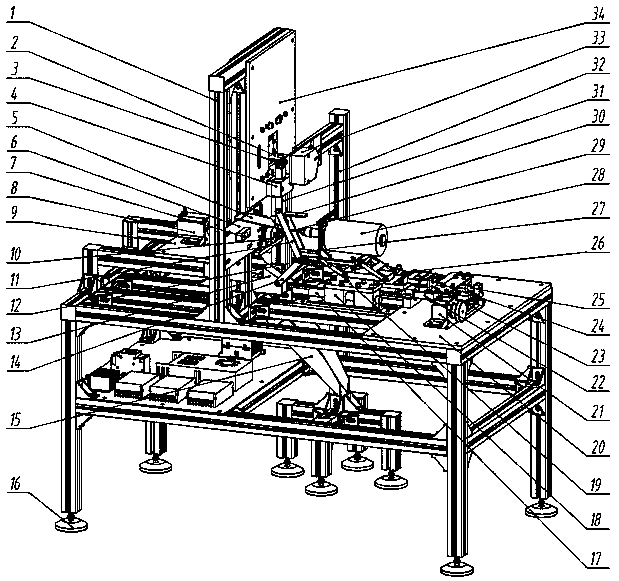

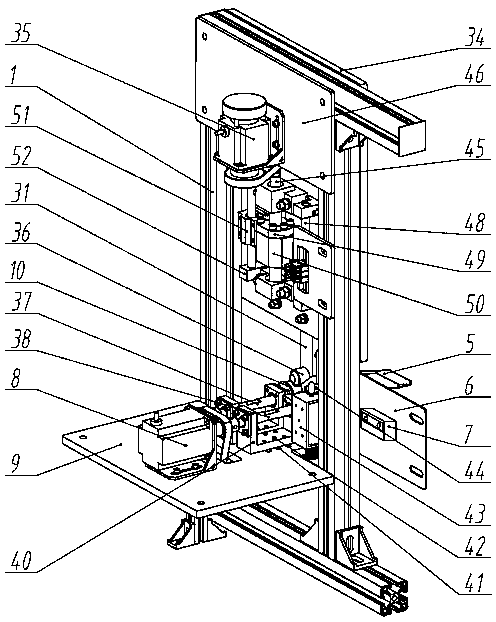

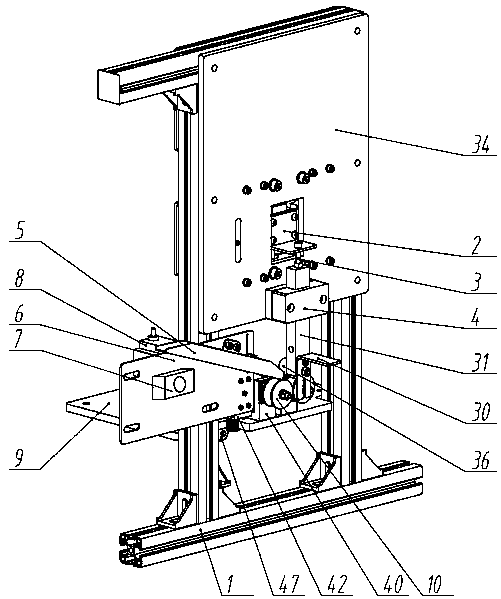

[0034] Such as figure 1 — Figure 7, the lotus kernel rolling centering test bench of the present invention includes a frame 1, a feeding mechanism, a rolling centering module, a centering module, a centering process parameter adjustment module, a centering rate online detection module, and a drilling axial feed force detection module, centering accuracy detection module and PLC control system.

[0035] The feeding mechanism is used to send lotus kernels to the rolling centering module, including a feeding trough 5, a feeding trough mounting plate 6, an electromagnet 43, and a material retaining plate 44. The feeding trough mounting plate is installed above the middle part of the frame 1, and the feeding trough 5 is installed on the front of the feeding trough mounting plate 6 at a certain inclination angle, on the side of the center distance adjustment mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com