Preparation equipment of water-borne epoxy resin emulsion

A technology of water-based epoxy resin and emulsion, which is applied in the direction of grain processing, etc., can solve the problems of inconvenient micron-level grinding of epoxy resin and inconvenient automatic discharge of finished products, so as to avoid insufficient grinding fineness, improve grinding effect, and increase The effect of the route of travel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

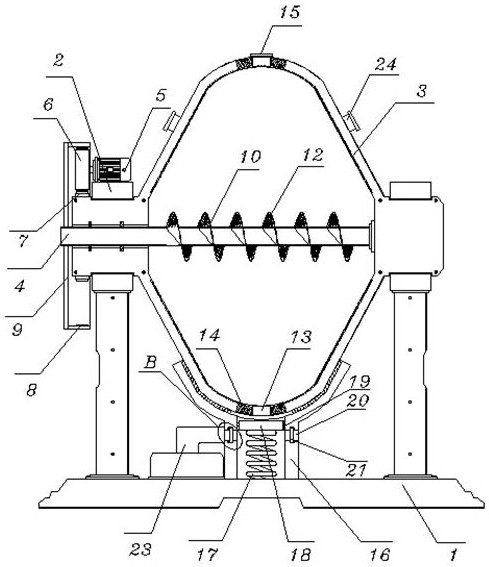

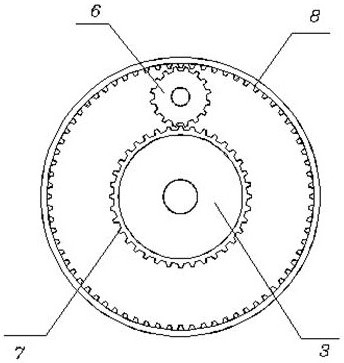

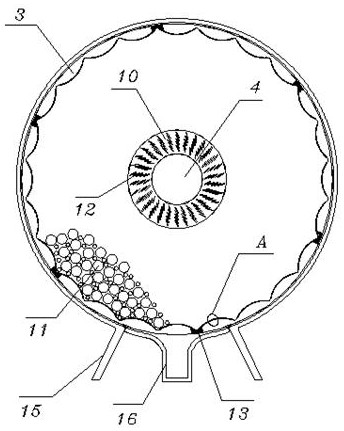

[0033] see Figure 1-5Including the base 1, the top of the base 1 is fixed with the installation frame 2, and the inner part of the top of the installation frame 2 is embedded with a roller 3, and the inner bearing of the roller 3 is installed with a horizontal shaft 4, and the outer side of the roller 3 is connected with a Material opening 24; also includes: motor 5, motor 5 is fixed on the top of installation frame 2, and the output end of motor 5 is connected with gear 6, and the upper and lower sides of gear 6 are meshed with gear ring 8 and gear sleeve 7 respectively, and The gear sleeve 7 is fixedly set on the end of the drum 3, and one side of the gear ring 8 is fixed with a mounting plate 9, and the mounting plate 9 is fixedly sleeved on one end of the horizontal shaft 4, and one end of the horizontal shaft 4 runs through the side of the drum 3 end, and the middle part of the horizontal axis 4 is provided with a spiral blade 10, and the grinding ball 11 is placed in th...

Embodiment 2

[0035] see figure 1 , image 3 and Figure 6-9 Among them, the middle part of the drum 3 is provided with a screen 13, and the side of the screen 13 is provided with a first magnetic block 14, and the first magnetic block 14 is embedded and fixed inside the drum 3, the stop ring 15, the stop ring 15 is sleeved on the outside of the middle part of the drum 3, and the bottom of the drum 3 is fitted with a material guide seat 16, and the cavity at the top of the material guide seat 16 is connected with a second magnetic block 18 through a spring 17, and the second magnetic block The side of 18 is fixed with rack 19, meanwhile rack 19 is movably installed on the inner wall of the cavity of material guide seat 16, and the side of material guide seat 16 is provided with opening 20, and the embedded movable installation in opening 20 There is a ring gear 21, and the ring gear 21 is located on one side of the rack 19, and the fan blade assembly 22 is installed in the ring gear 21, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com