Screening system and process method for double sorting of grain particles

A grain particle sorting technology, applied in chemical instruments and methods, separating solids from solids by air flow, filtering and sieving, etc. Material structure, primary sorting of undisclosed broken particles, etc., to achieve the effect of increasing sorting effect and sorting efficiency, fast rolling speed and slow rolling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

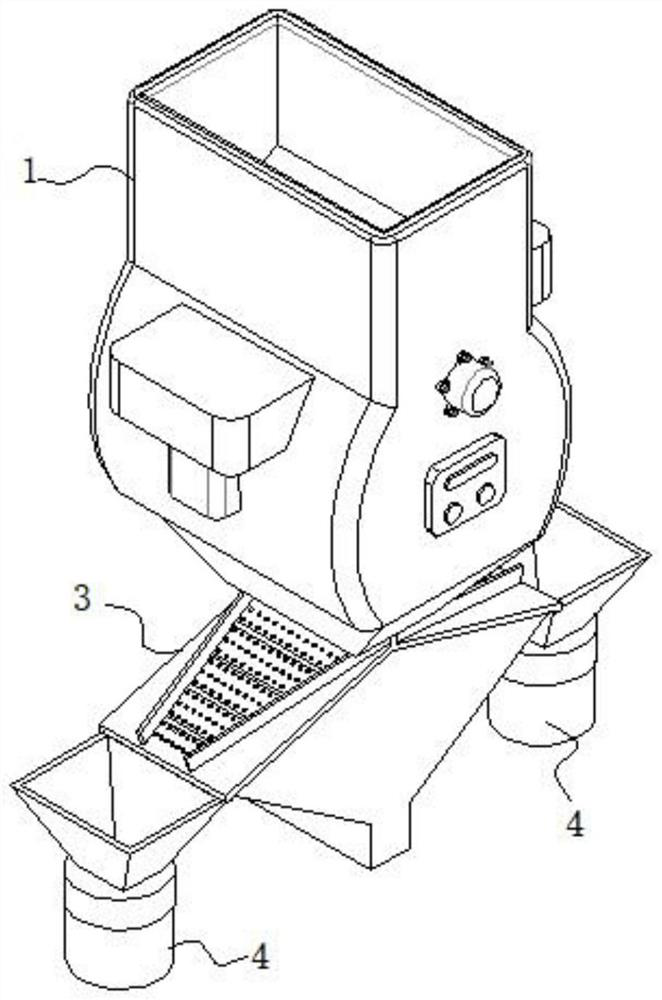

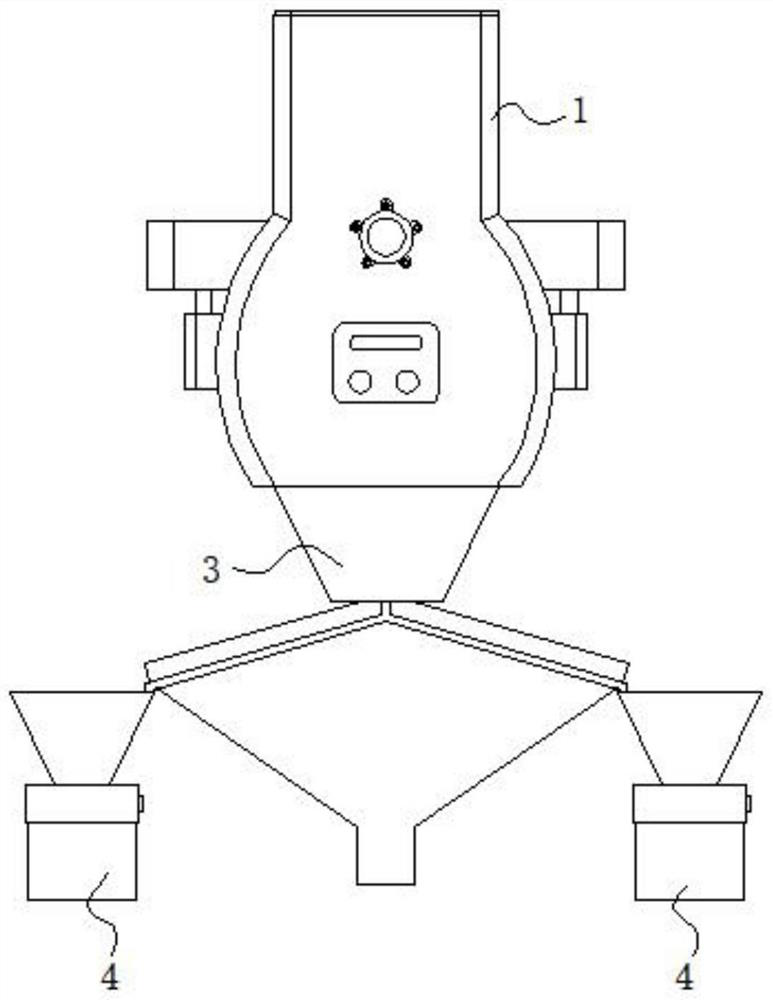

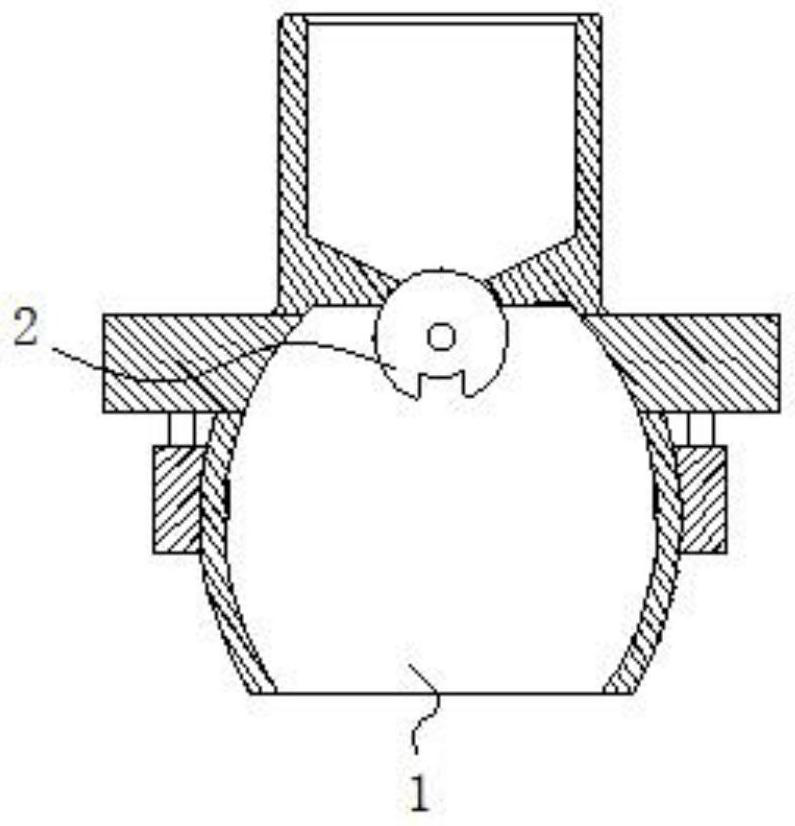

[0045] see Figure 1-14 , the present invention is a screening system for double sorting of grain particles, comprising a dust suction mechanism 1, and a rotary sorting mechanism 2 for discharging materials in a gap is arranged inside the dust suction mechanism 1, which is used as a primary sorting, and is used in the rotary sorting During the intermittent discharge process of the mechanism 2, the raised debris is sucked away by the dust suction mechanism 1, and the bottom of the dust suction mechanism 1 is fixed with a two-way sorting mechanism 3, which acts as a secondary sorting to remove the grain particles of the debris Falling onto the two-way sorting mechanism 3, the two-way sorting mechanism 3 carries out two-way dispersion to increase the sorting effect and efficiency of grain particles, and both sides of the two-way sorting mechanism 3 are connected with an anti-blocking collection mechanism 4;

[0046] The two-way sorting mechanism 3 includes No. 1 collection hopper...

Embodiment 2

[0062] A process method for a screening system for double sorting of grain particles, comprising the steps of:

[0063] SS01 stores the grain in the material storage space above the gathering table 106 of the hollow vacuum shell 101, the rotary sorting mechanism 2 first rotates left and right in a small range, and the fine grain particles first pass through the No. 2 sieve structure 202, and then rotate and sort The selection mechanism 2 starts to rotate, so that the large-grain grain enters the hollow dust suction housing 101 along with the gap feed port 203, and realizes the discharge of the rotary separation mechanism 2. Through this small left and right rotation-rotary discharge-left and right The alternate operation mode of small rotation and rotating discharge realizes the intermittent discharge of the grain particles stored on the top of the hollow vacuum housing 101;

[0064]SS02 uses dust collection equipment 102 to suck away small impurities such as debris in the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com