Waste plastic cement stabilized macadam and preparation process thereof

A technology for cement stabilizing gravel and waste plastics, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as affecting road stability and durability, reducing structural integrity, and reducing service life. , to achieve superior ductility and deformation ability, improve the ability to resist deformation, and improve the effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

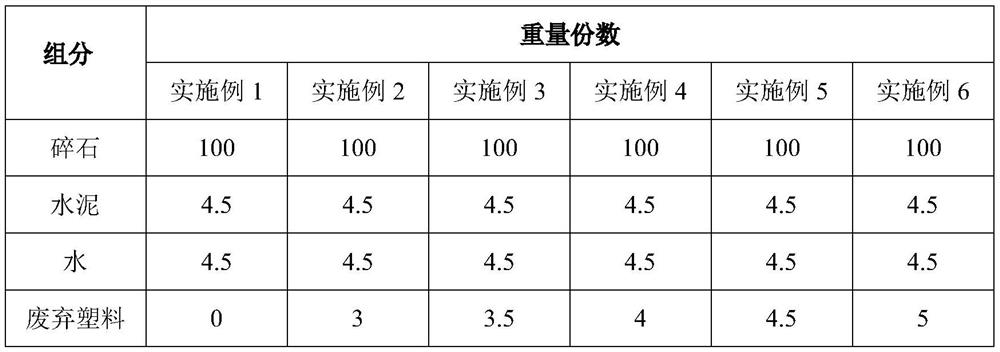

Embodiment 1

[0023] 100 parts of crushed stone, 4.5 parts of cement, and 4.5 parts of water. After measuring each component in the dry material according to the weight part, uniformly stir and mix, and then add water and uniformly stir to obtain ordinary cement stabilized crushed stone.

Embodiment 2

[0025] 100 parts of gravel, 4.5 parts of cement, 4.5 parts of water, and 3 parts of waste plastics. After measuring each component in the dry material according to parts by weight, uniformly stir and mix, and then add water and uniformly stir to obtain ordinary cement stabilized gravel.

Embodiment 3

[0027] 100 parts of crushed stone, 4.5 parts of cement, 4.5 parts of water, and 3.5 parts of waste plastics. After measuring each component in the dry material according to parts by weight, uniformly stir and mix, and then add water and uniformly stir to obtain ordinary cement stabilized gravel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com