Autoclaved aerated concrete anti-seepage building block and preparation method thereof

An autoclaved aerated concrete technology, which is applied in the manufacture of tools, ceramic products, and other household appliances, can solve the problems of not meeting the requirements of building waterproof and anti-seepage, achieve rich imagination, improve work efficiency, and speed up construction progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

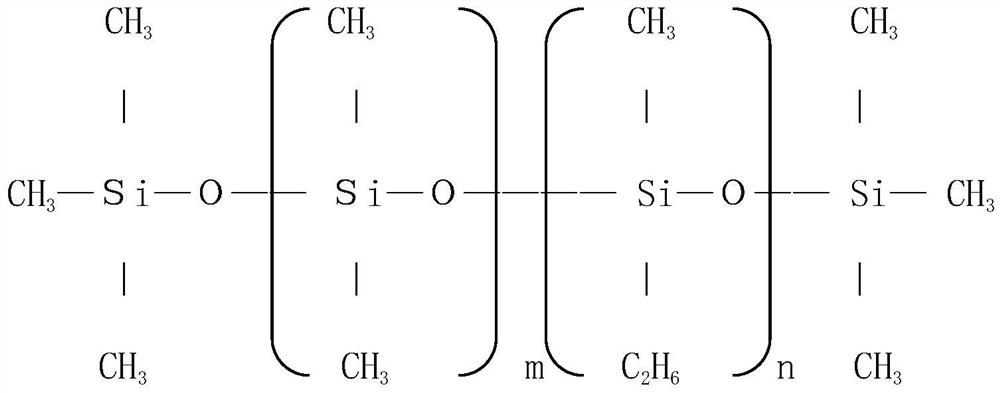

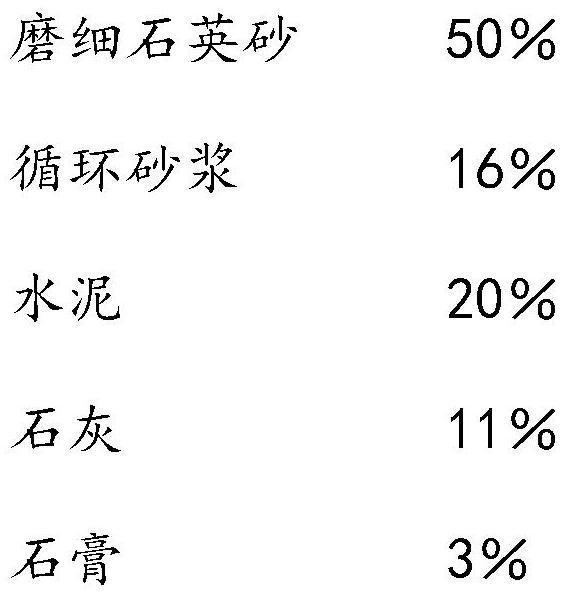

[0031] An autoclaved air-entrained concrete anti-seepage block, including ground quartz sand, cement, lime, and gypsum as the main base material, and aluminum powder as the foaming agent, and also includes a hydrophobic anti-seepage agent. The percentages are as follows, 50% of finely ground quartz sand, 16% of circulating mortar, 20% of cement, 11% of lime, 3% of gypsum, 0.08% of aluminum powder paste and 0.03% of hydrophobic anti-seepage agent can also be added. By using the internal anti-seepage agent to add hydrophobic groups to the product itself and the bubble wall, adding an internal waterproof agent to form a layer of bubble film on the contact surface between the bubble wall and water of the product, reducing the water seepage of the pores wall voids and capillaries, Improve the hydrophobicity of the air-entrained concrete pore wall, thereby improving its impermeability.

Embodiment 2

[0033] An autoclaved air-entrained concrete anti-seepage block, including ground quartz sand, cement, lime, and gypsum as the main base material, and aluminum powder as the foaming agent, and also includes a hydrophobic anti-seepage agent. The percentages are as follows, 50% of ground quartz sand, 16% of circulating mortar, 20% of cement, 11% of lime, 3% of gypsum, 0.08% of aluminum powder paste and 0.04% of hydrophobic anti-seepage agent can also be added. By using the internal anti-seepage agent to add hydrophobic groups to the product itself and the bubble wall, adding an internal waterproof agent to form a layer of bubble film on the contact surface between the bubble wall and water of the product, reducing the water seepage of the pores wall voids and capillaries, Improve the hydrophobicity of the air-entrained concrete pore wall, thereby improving its impermeability.

Embodiment 3

[0035] An autoclaved air-entrained concrete anti-seepage block, including ground quartz sand, cement, lime, and gypsum as the main base material, and aluminum powder as the foaming agent, and also includes a hydrophobic anti-seepage agent. The percentages are as follows, 50% of ground quartz sand, 16% of circulating mortar, 20% of cement, 11% of lime, 3% of gypsum, 0.08% of aluminum powder paste and 0.05% of hydrophobic anti-seepage agent can also be added. By using the internal anti-seepage agent to add hydrophobic groups to the product itself and the bubble wall, adding an internal waterproof agent to form a layer of bubble film on the contact surface between the bubble wall and water of the product, reducing the water seepage of the pores wall voids and capillaries, Improve the hydrophobicity of the air-entrained concrete pore wall, thereby improving its impermeability.

[0036] Principle of the present invention is:

[0037] After the autoclaved aerated concrete is thicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com