Pavement repairing method

A road surface repair and pavement technology, which is applied to roads, roads, pavement details, etc., can solve other road traffic pressures, affect people's normal travel, accidents and other problems, so as to prevent driving hazards, shorten concrete curing time, and enhance compression resistance Effects of Strength and Connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

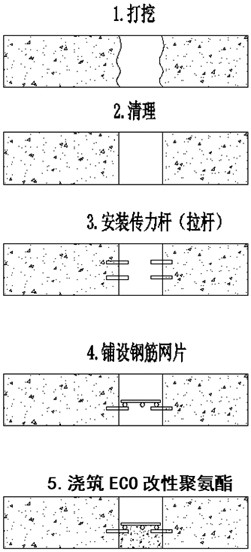

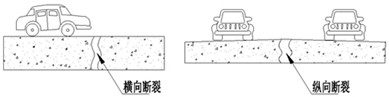

[0031] Such as figure 1 and image 3 As shown, the present embodiment provides a road repair method, the specific steps are as follows:

[0032] S10: Excavate on the transverse fractured road surface, remove the fractured part according to the excavation situation, the depth of the excavation is greater than the depth of the fracture, and the notch of the excavation is regular to facilitate the cutting of the steel mesh;

[0033] S20: cleaning and trimming the four walls of the notch, and chiseling the joint parts of the notch;

[0034] S30: Due to the wide and shallow notch of the transversely fractured pavement, when installing the dowel bars, select 5 points with the same average distance to install the dowel bars, try to drive the dowel bars horizontally into the wall of the notch, and each dowel bar in the same horizontal plane;

[0035] S40: Cut the reinforcement mesh according to the shape of the notch so that it can be put into the notch evenly, place the reinforcemen...

Embodiment 2

[0039] Such as figure 1 , figure 2 and image 3 As shown, the present embodiment provides a road repair method, the specific steps are as follows:

[0040] S10: Excavate on the longitudinally fractured road surface, remove the fractured part according to the excavation situation, the depth of excavation is greater than the depth of the fracture, and the excavated notch is regular to facilitate the cutting of the steel mesh;

[0041] S20: cleaning and trimming the four walls of the notch, and chiseling the joint parts of the notch;

[0042] S30: Due to the small and deep notch of the longitudinally fractured pavement, when installing the dowel bars, select three points with the same average distance to install the dowel bars, try to drive the dowel bars horizontally into the wall of the notch, and each dowel bar in the same horizontal plane;

[0043] S40: Cut the reinforcement mesh according to the shape of the notch so that it can be placed in the notch flatly, place the ...

Embodiment 3

[0051] Such as figure 1 , figure 2 and image 3 As shown, the present embodiment provides a road repair method, the specific steps are as follows:

[0052] S10: Excavate on the longitudinally fractured road surface. According to the excavation situation, remove the fractured part. The depth of excavation is greater than the depth of the fracture. Since the depth of the longitudinal fracture is deep, the vertical notch is not conducive to the installation of the dowel bar , trim the excavated notches into pit rows;

[0053] S20: cleaning and trimming the four walls of the notch, and chiseling the joint parts of the notch;

[0054] S30: According to the size of each cross-section of the pit-shaped notch, select the number of dowel bars to install, 3 on the first layer, 5 on the second layer, and 7 on the third layer, and choose points with the same average distance to install the force transmission Rod, drive the dowel rod horizontally into the notch wall as far as possible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com