Tidal power generator of self-lubricating blade bearing based on ocean energy

A self-lubricating, generator technology, applied in ocean energy power generation, engine lubrication, hydropower generation, etc., can solve problems such as reducing the energy conversion efficiency of tidal generators, energy consumption, and reducing the rotational speed of turbine blades and shafts. Conversion efficiency, realize recycling, avoid the effect of speed reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

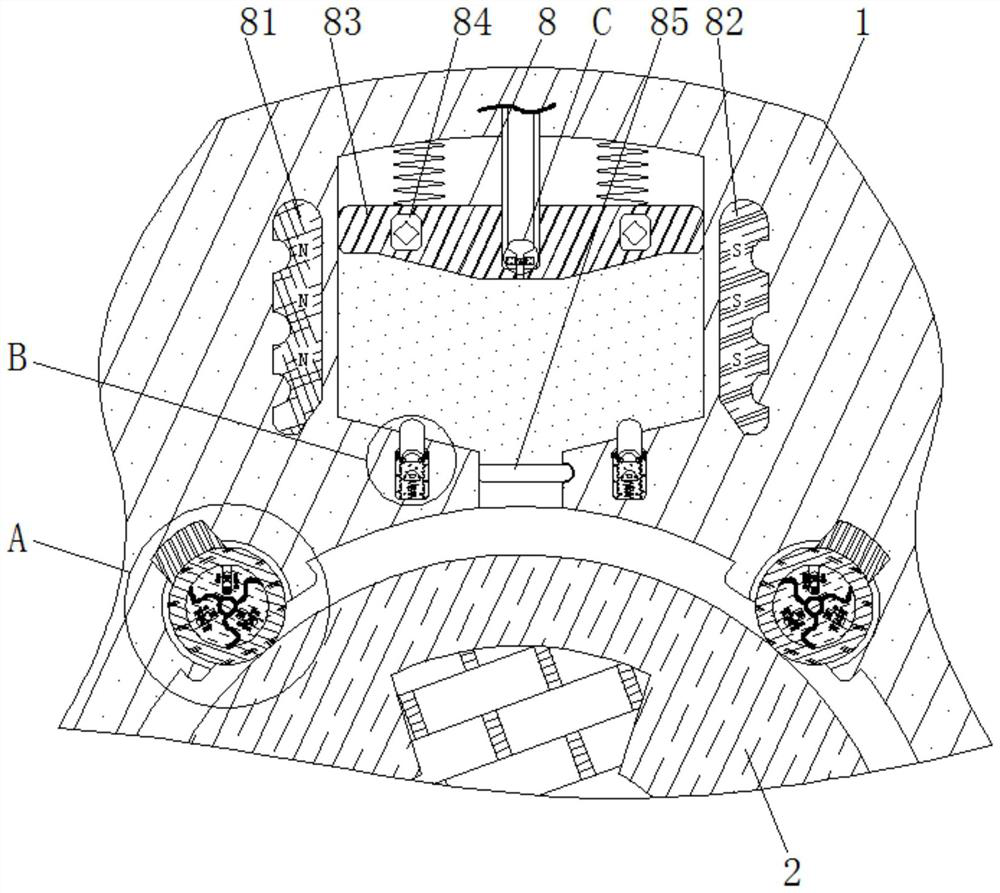

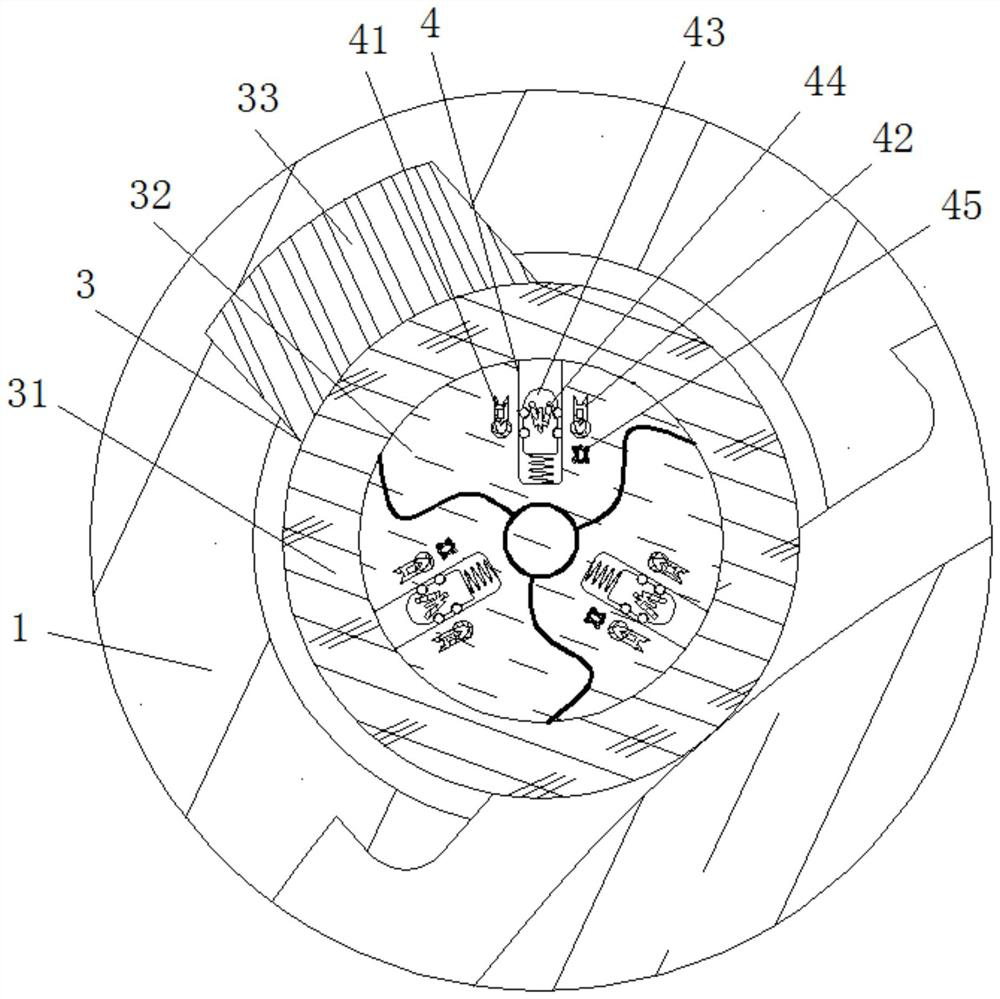

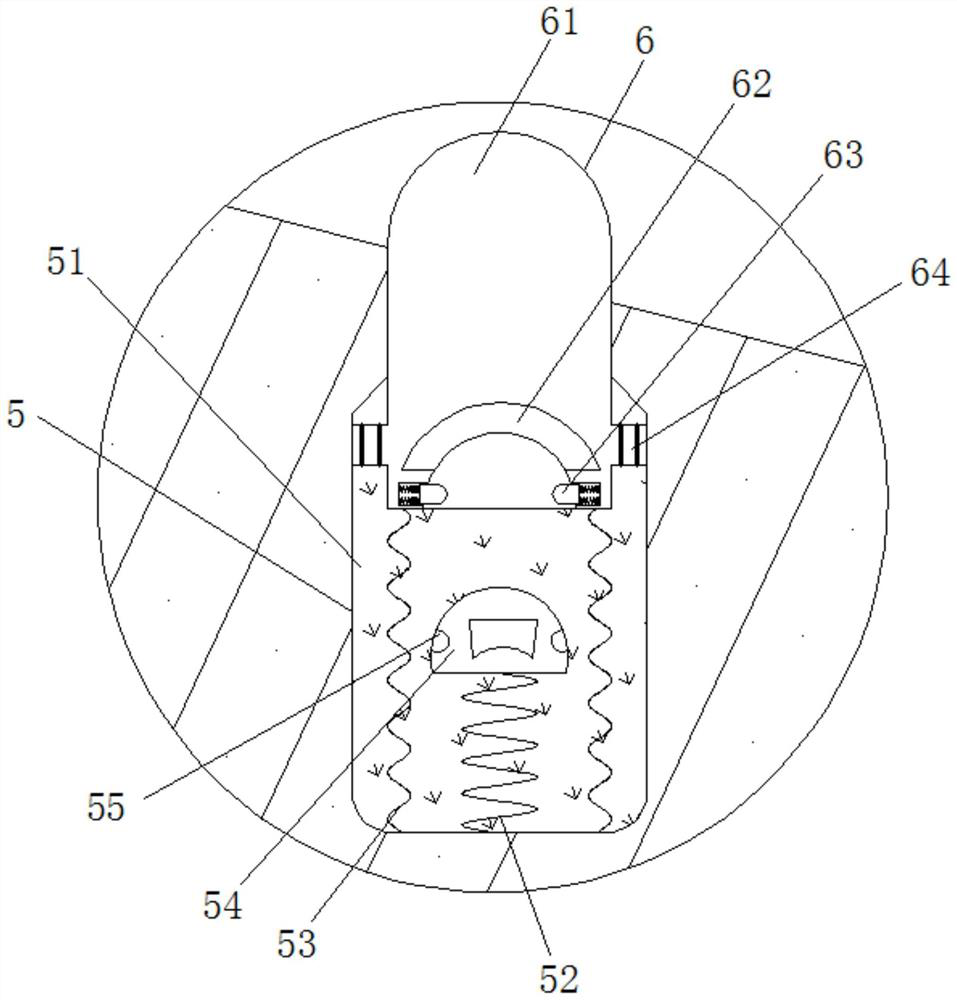

[0024] see Figure 1-4 , a tidal generator based on self-lubricating blade bearings of ocean energy, including a housing 1, a rotating shaft 2, a rotating mechanism 3, a triggering mechanism 4, a connecting mechanism 5, a sliding mechanism 6, an opening and closing mechanism 7 and an extrusion mechanism 8 , the inner wall of the housing 1 is movably connected with a rotating shaft 2 , the inner wall of the housing 1 is movably connected with a rotating mechanism 3 , the rotating mechanism 3 includes a friction ring 31 , a connecting roller 32 and a friction block 33 , and the inner wall of the casing 1 is movably connected with a connecting roller 32, the outer side of the connecting roller 32 is fixedly connected with a friction ring 31, the inner wall of the housing 1 is fixedly connected with a friction block 33, the friction block 33 is in sliding connection with the friction ring 31, the friction ring 31 is in sliding connection with the rotating shaft 2, and the rotating ...

Embodiment 2

[0027] see Figure 1-4 , a tidal generator based on self-lubricating blade bearings of ocean energy, including a housing 1, a rotating shaft 2, a rotating mechanism 3, a triggering mechanism 4, a connecting mechanism 5, a sliding mechanism 6, an opening and closing mechanism 7 and an extrusion mechanism 8 , the inner wall of the housing 1 is movably connected with a rotating shaft 2 , the inner wall of the housing 1 is movably connected with a rotating mechanism 3 , the rotating mechanism 3 includes a friction ring 31 , a connecting roller 32 and a friction block 33 , and the inner wall of the casing 1 is movably connected with a connecting roller 32, the outer side of the connecting roller 32 is fixedly connected with a friction ring 31, the inner wall of the housing 1 is fixedly connected with a friction block 33, the friction block 33 is in sliding connection with the friction ring 31, the friction ring 31 is in sliding connection with the rotating shaft 2, and the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com