Method for ultrasonically detecting texture of metal material

A metal material, ultrasonic testing technology, applied in the direction of using sonic/ultrasonic/infrasound for material analysis, material analysis, and sonic/ultrasonic/infrasonic analysis of solids, etc. Large, good statistical, easy to achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

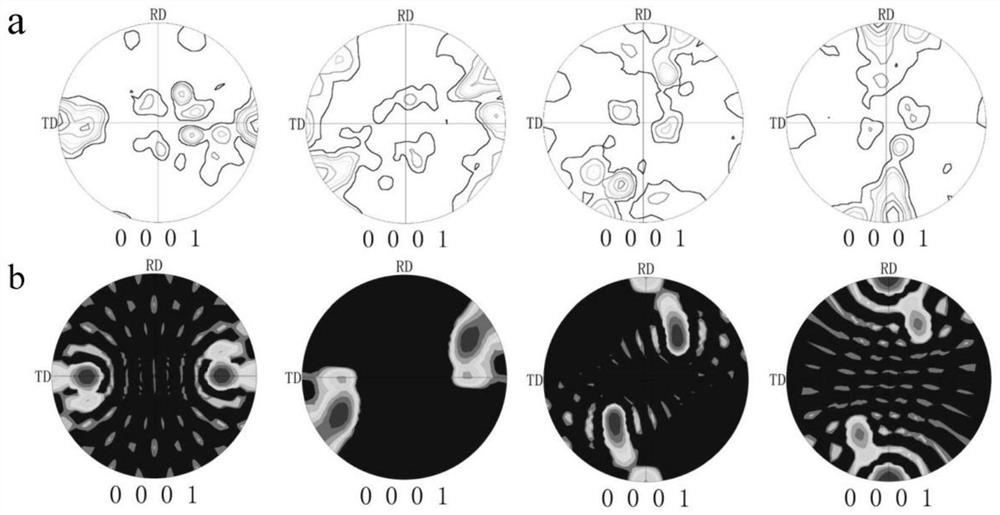

Image

Examples

Embodiment 1

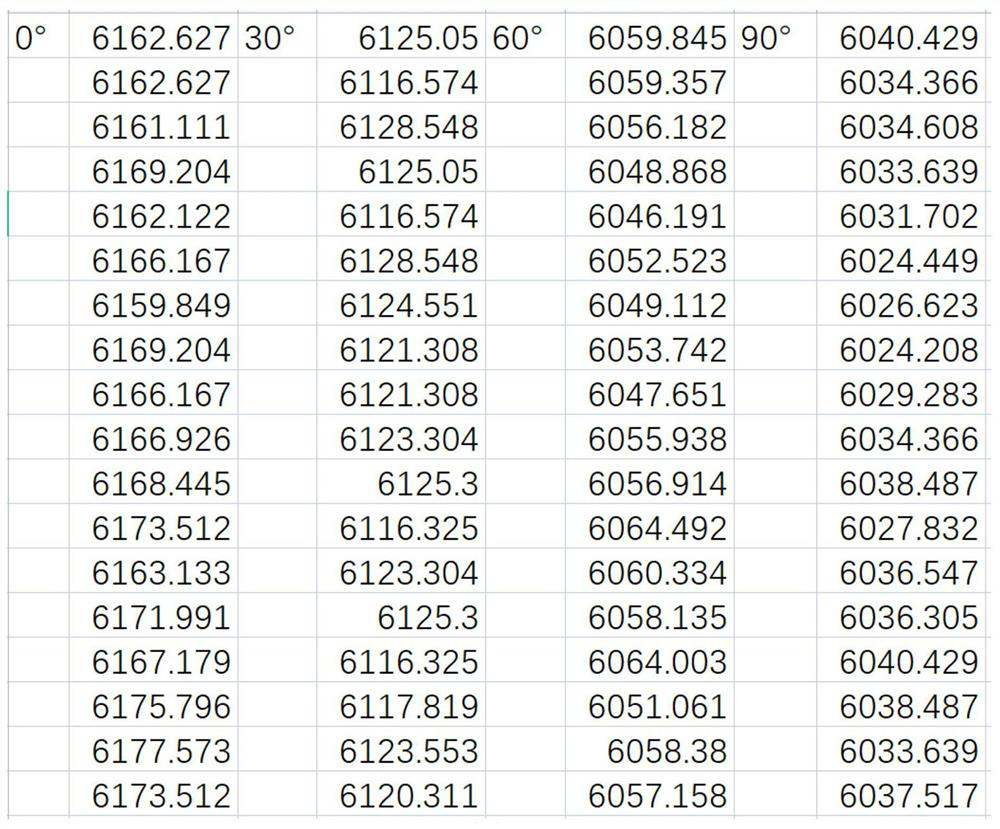

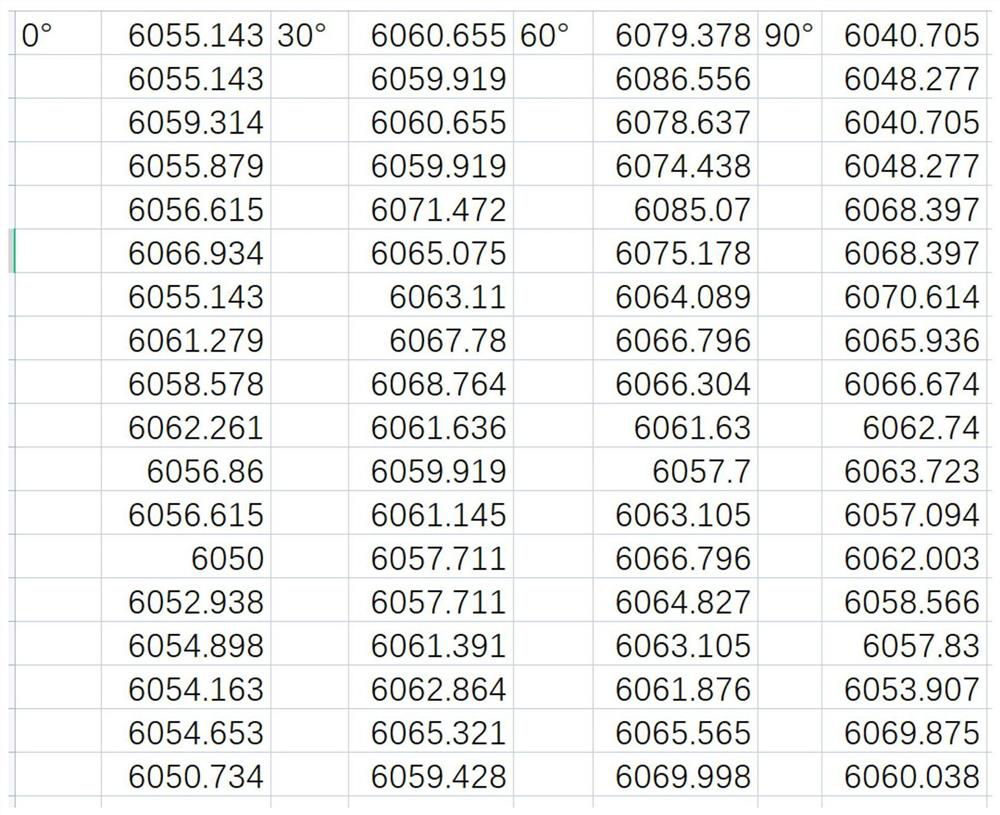

[0085] The detection object of this embodiment is industrial pure titanium TA2 hot-rolled plate, and its concrete texture detection process is:

[0086] Step 1. Ultrasonic testing sample processing

[0087] The size of the TA2 hot-rolled plate is 200mm×150mm×24mm (rolling direction×normal direction×normal direction), and wire cutting is used to take samples along the angles of 0°, 30°, 60°, and 90° with the rolling direction of the plate. The sample size is 17mm×18mm×24mm, and the sample is processed into a 15mm×15mm×15mm cube using a machining center, and the rolling direction and normal direction are marked on the surface of the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com