High-flux super-resolution laser direct writing system based on microlens array and DMD

A microlens array and laser direct writing technology, applied in the field of optical engineering, can solve the problems of limiting parallel laser direct writing speed, inability to achieve three-dimensional processing by near-field probes, and inability to further increase the number of near-field probes and microlens arrays. , to achieve the effect of improving the direct writing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below through the examples and accompanying drawings, but the protection scope of the present invention should not be limited by this.

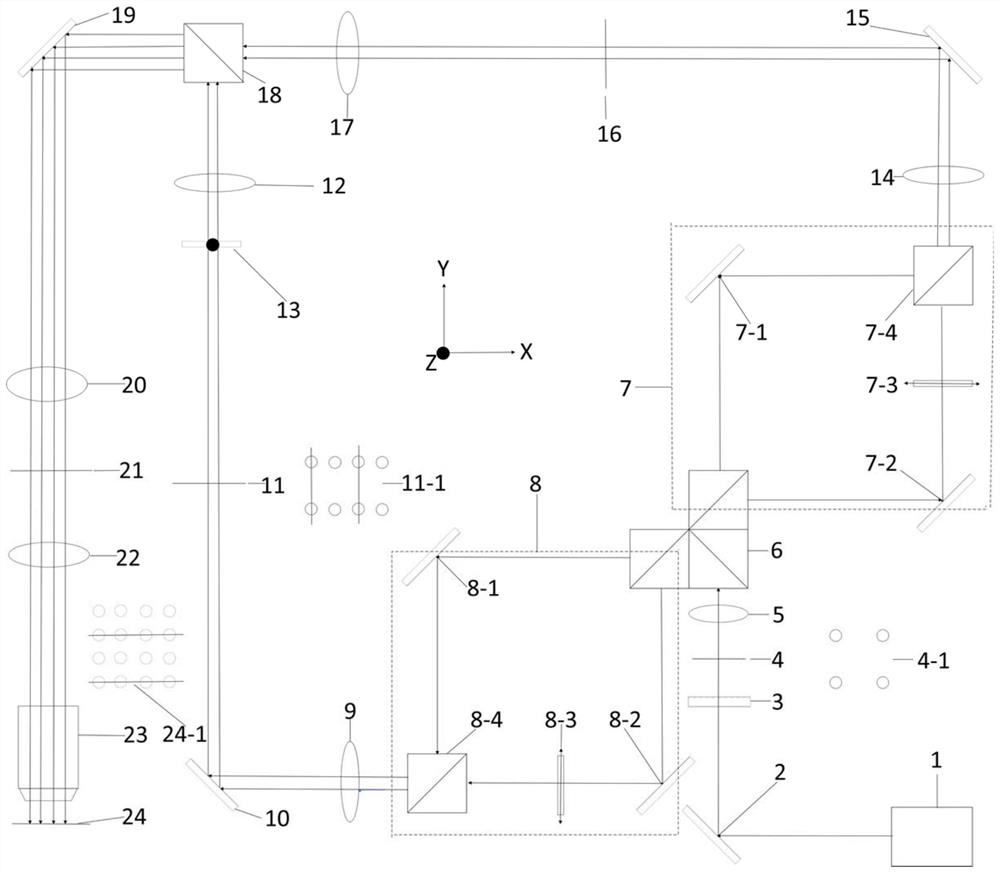

[0026] Such as figure 1 As shown, a high-throughput super-resolution laser direct writing system based on a microlens array and a DMD of the present invention includes: a laser 1, mirrors 2, 10, 15, 19, a microlens array 3, a collimating mirror 5, and four Beam splitter 6, beam number multiplying units 7, 8, lenses 9, 12, 14, 17, 20, 22, flat beam displacement element 13, double beam combiner 18, objective lens 23 and photoresist.

[0027] Laser 1 is a femtosecond laser with a pulse period of 10fs-250s, and the laser wavelength range is 200-800nm; especially when the wavelength is about 400nm, the direct writing resolution can reach 50nm. The laser output mode is spatial light output, and the beam diameter is not smaller than the diagonal length D of the microlens array 3 (or not smaller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com