Motor controller using phase change material to absorb heat

A technology of motor controllers and phase change materials, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems of insufficient heat absorption capacity of aluminum plates, burnout, thermal failure of electronic devices, etc., and achieve the effect of solving the problem of steady-state heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

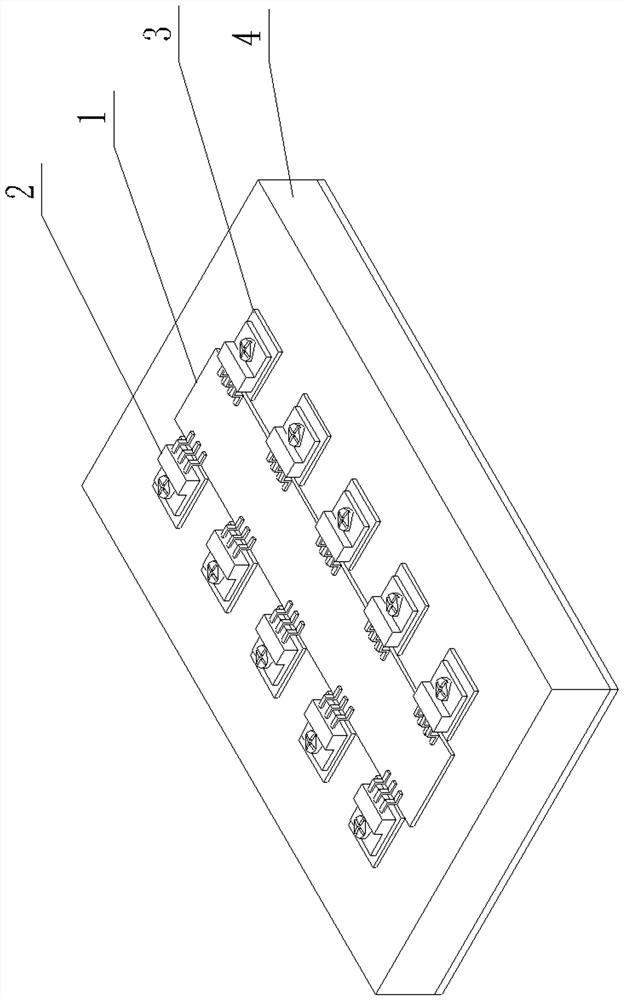

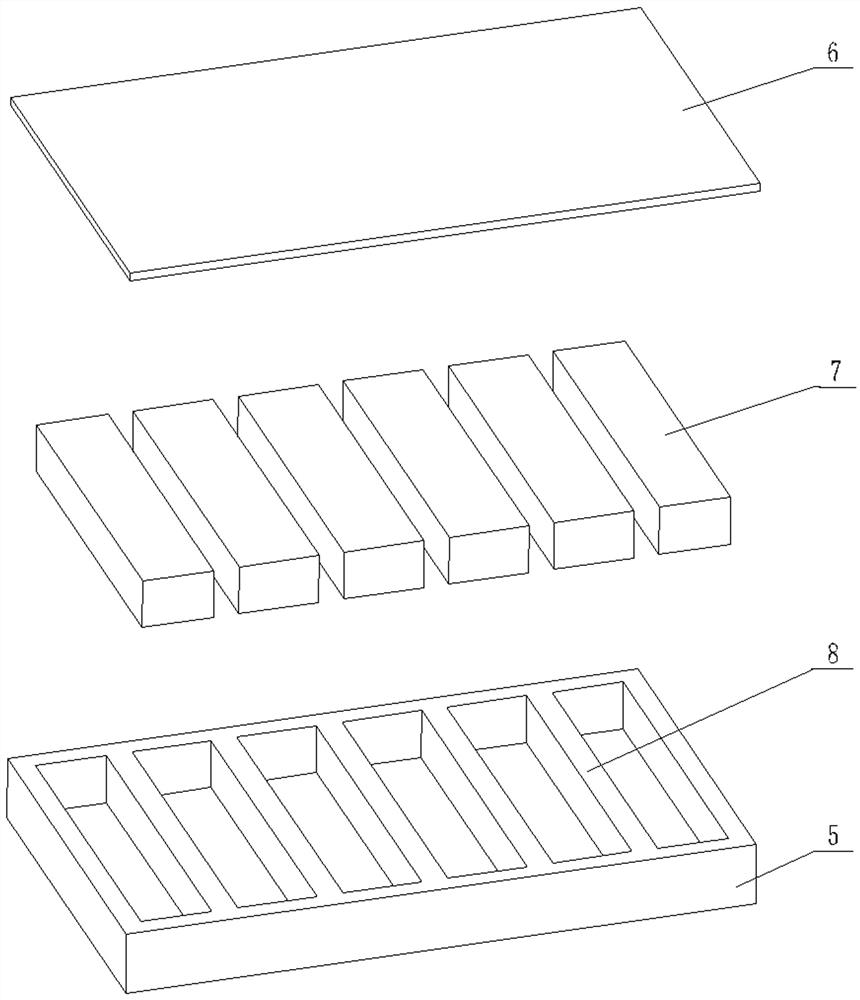

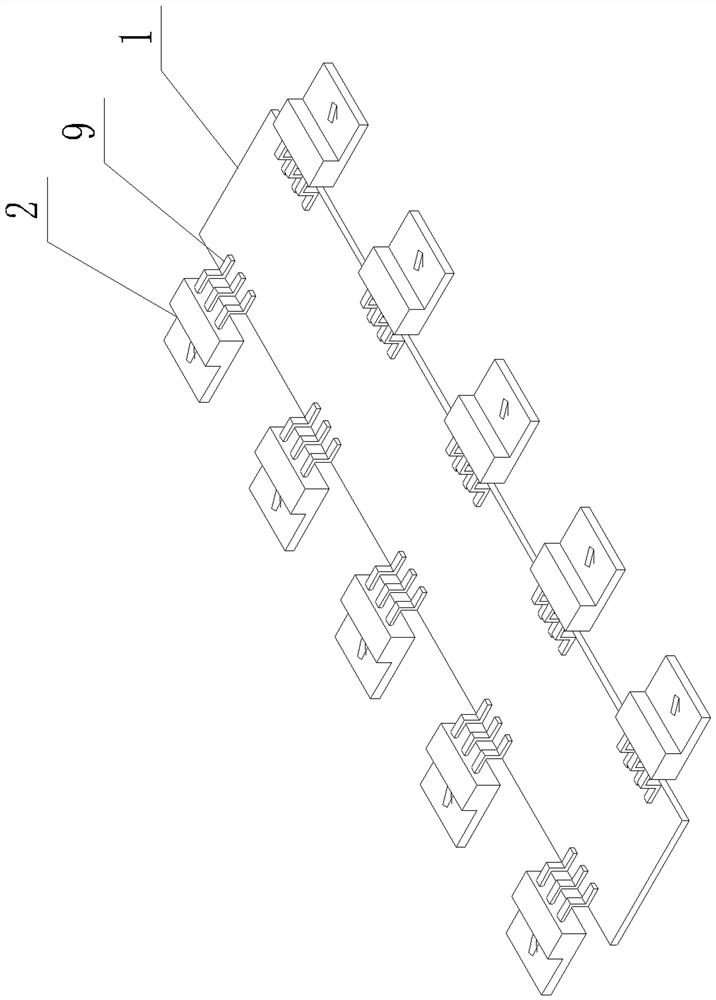

[0019] Such as Figure 1 to Figure 3 As shown, a motor controller using phase change materials to absorb heat includes a conductive mechanism, the conductive mechanism includes a PCB board 1 located on the upper surface of the housing mechanism, and a MOS tube 2 connected to the PCB board 1 through solder pins 9, The lower surface of the MOS tube 2 is fixedly connected to the upper surface of the housing mechanism through the gasket 3, and the PCB board is fixedly connected to the upper surface of the housing mechanism, and also includes a gasket 3 located below the conductive mechanism, located below the gasket 3 and used For the heat-absorbing mechanism 4 that absorbs the heat generated by the conductive mechanism, the gasket 3 is made of insulating and heat-conducting material, separated by the gasket 3 between the MOS tube and the heat-absorbing plate, and finally the MOS tube, the gasket 3, The tops of the heat-absorbing mechanism 4 are tightly locked together. The heat-a...

Embodiment 2

[0021] Such as Figure 1 to Figure 3 As shown, a motor controller using phase change materials to absorb heat includes a conductive mechanism, the conductive mechanism includes a PCB board 1 located on the upper surface of the housing mechanism, and a MOS tube 2 connected to the PCB board 1 through solder pins 9, The lower surface of the MOS tube 2 is fixedly connected to the upper surface of the housing mechanism through the gasket 3, and the PCB board is fixedly connected to the upper surface of the housing mechanism, and also includes a gasket 3 located below the conductive mechanism, located below the gasket 3 and used For the heat-absorbing mechanism 4 that absorbs the heat generated by the conductive mechanism, the gasket 3 is made of insulating and heat-conducting material, separated by the gasket 3 between the MOS tube and the heat-absorbing plate, and finally the MOS tube, the gasket 3, The tops of the heat-absorbing mechanism 4 are tightly locked together. The heat-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com