Steel sheet having excellent uniform elongation and work hardening rate, and method for producing same

A technology of uniform elongation and work hardening, applied in chemical instruments and methods, manufacturing tools, improvement of process efficiency, etc., can solve the problems of dents in the furnace, poor weldability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

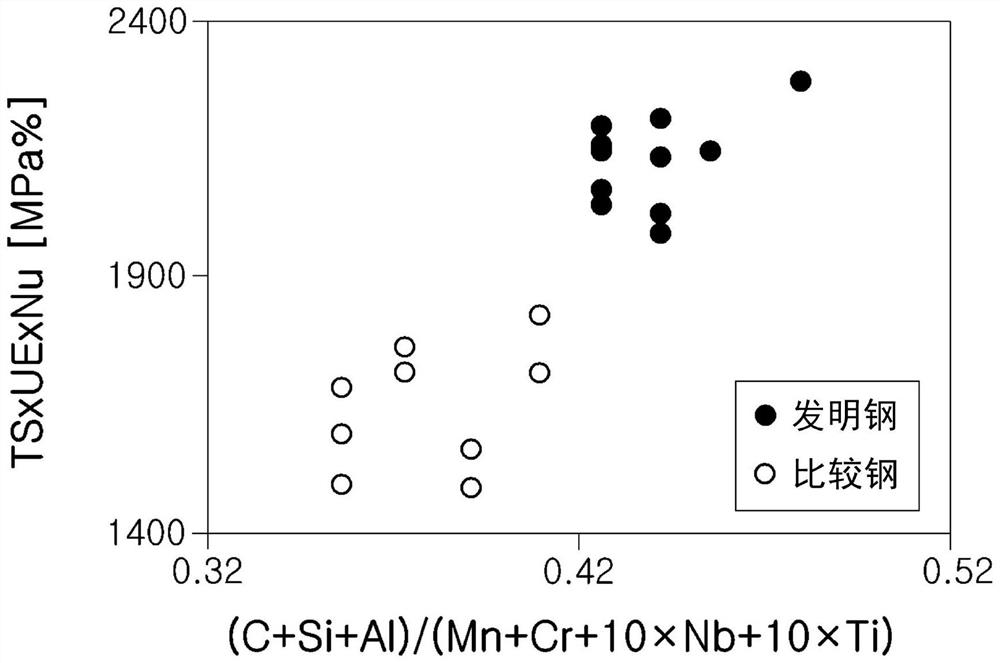

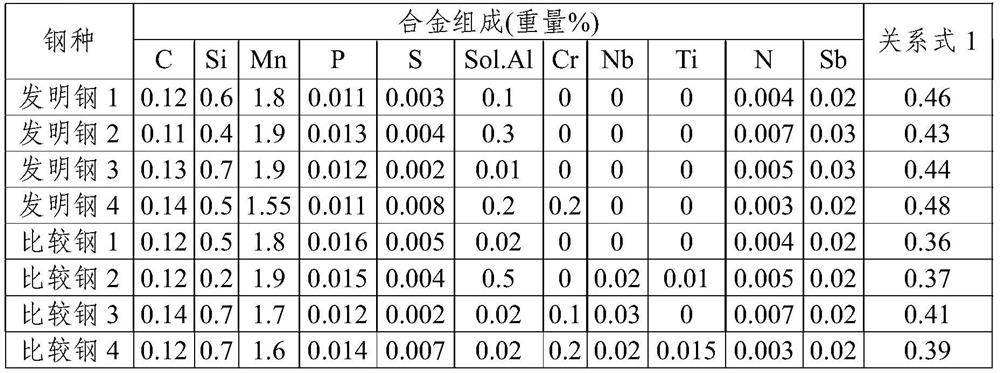

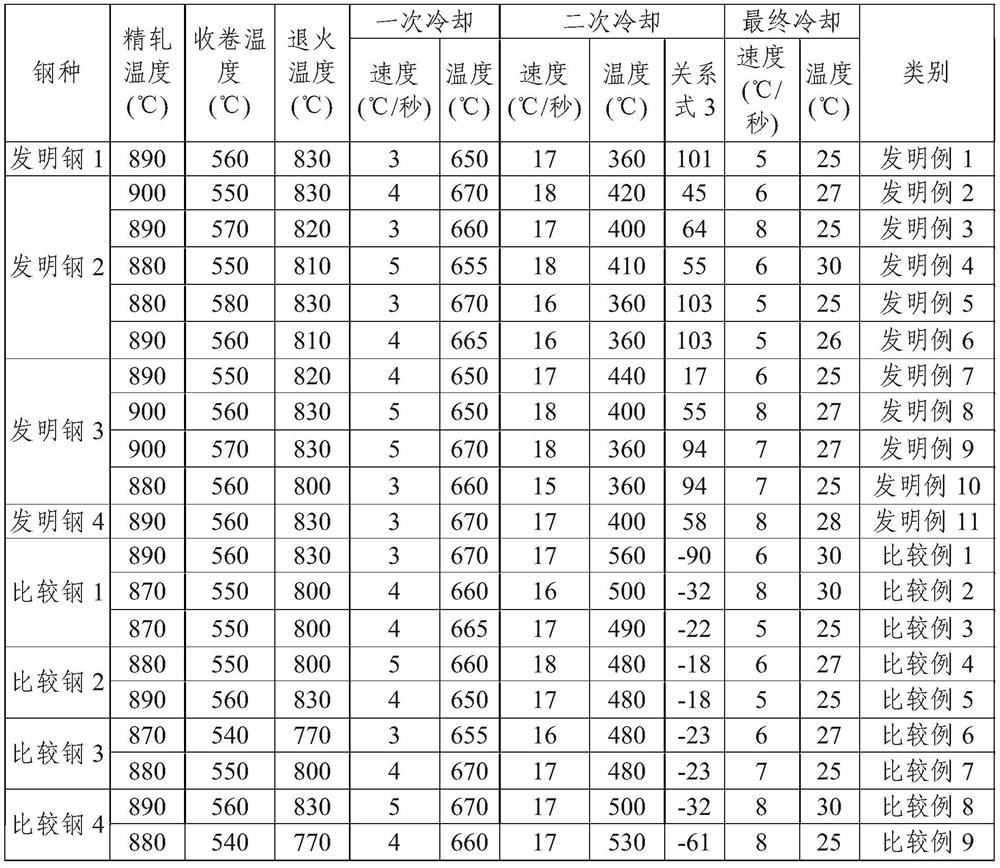

[0165] After manufacturing a billet having an alloy composition shown in Table 1 below, the billet was heated to a temperature range of 1100-1300°C, and then hot finish rolling was performed at a temperature shown in Table 2 below to manufacture a hot-rolled steel sheet, The hot-rolled steel sheet was loaded into a coiling furnace and coiled, and then furnace-cooled to room temperature at a rate of 0.002°C / sec. At this time, the coiling temperature of each hot-rolled steel sheet is shown in Table 2 below.

[0166] Thereafter, each hot-rolled steel sheet was pickled, then cold-rolled at a cold-rolling reduction of 40-70%, thereby manufacturing a cold-rolled steel sheet, and then subjected to continuous annealing treatment under the conditions shown in Table 2 below, and then classified. Stage cooling (primary cooling and secondary cooling), and then keep at the secondary cooling termination temperature for more than 30 seconds. The holding time is no more than 200 seconds.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com