Dispersion machine for processing graphene modified PTC (Positive Temperature Coefficient) thermosensitive conductive ink

A graphene modified, conductive ink technology, applied in mixers, mixer accessories, mixers with rotary stirring devices, etc., can solve problems such as splashing, inability to clean and scrape ink, and ink easily splashing, and increase sealing. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

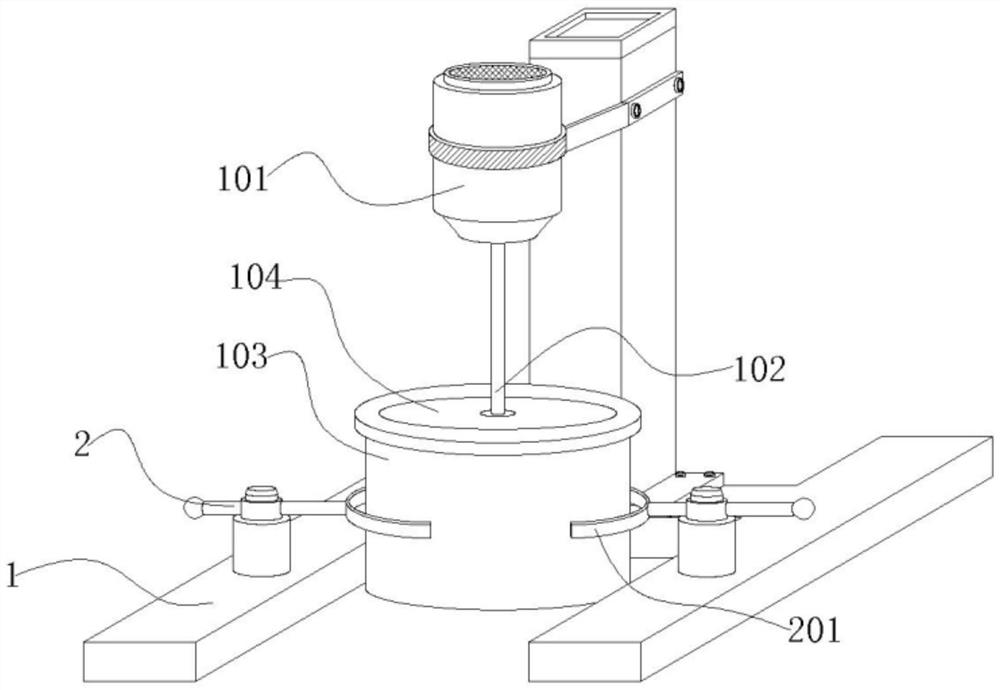

[0031] Embodiment 1: a kind of dispersing machine for processing of graphene modified PTC thermosensitive conductive ink, comprises device main body 1, and the upper end of device main body 1 is equipped with motor 101, and the lower end of motor 101 is rotated with stirring support 102, and the lower end of device main body 1 A material barrel 103 is installed, and the upper end of the material barrel 103 is movably nested and connected with a cover plate 104. Both sides of the device main body 1 are provided with a limiting mechanism that can quickly clamp both sides of the material barrel 103, and the inside of the material barrel 103 is provided with A transmission mechanism that can automatically scrape the upper end of the cover plate 104;

[0032] Wherein: the inside of the cover plate 104 runs through a hole, the two sides of the hole are provided with grooves, the motor 101 is electrically connected to the power supply through the power cord, the stirring support 102 r...

Embodiment 2

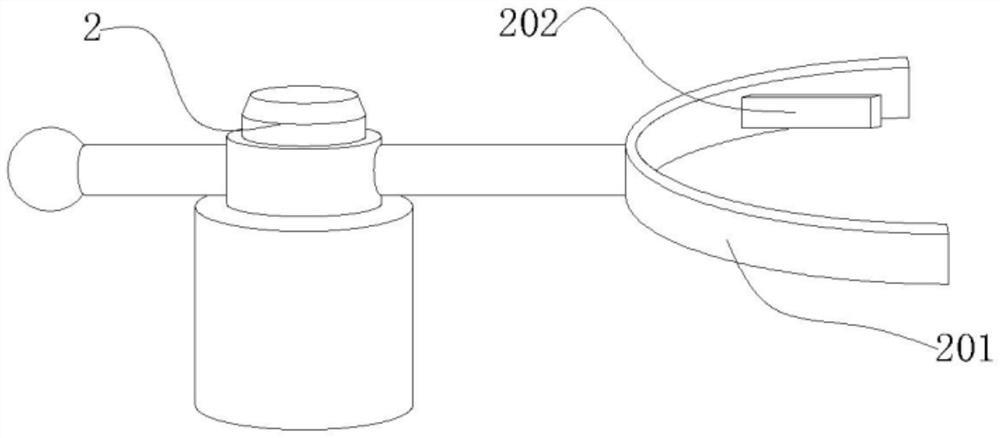

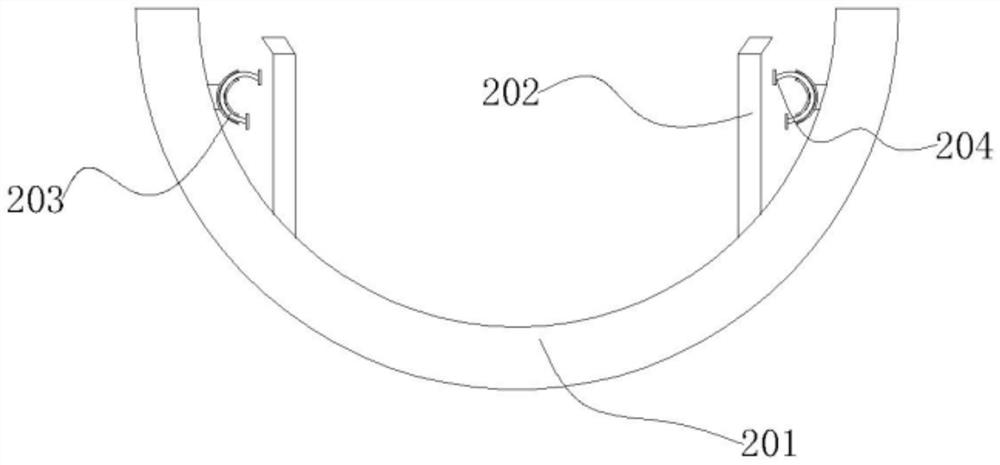

[0033] Embodiment 2: with reference to instruction manual figure 1 , 2 , 3 and 5, it can be seen that the difference between embodiment 2 and embodiment 1 is that the limiting mechanism includes a clamping frame 2, a clamping ring 201, a swash plate 202, a collar 203, a limiting ring 204 and a roller 3, the clamping The holder 2 is installed on both sides of the lower end of the device main body 1, the clamping ring 201 slides on one side of the clamping frame 2, the swash plate 202 is embedded on both sides of the clamping ring 201, and the collar 203 is installed on the clamping ring 201 close to On both sides of the swash plate 202 , the limit ring 204 slides through the outer side of the sleeve 203 , and the roller 3 rotates on both sides inside the cover plate 104 ;

[0034] Wherein: the clamping frame 2, the clamping frame 2 is arranged on both sides of the material barrel 103, and the clamping frame 2 is convenient for the clamping ring 201 to limit the both sides of t...

Embodiment 3

[0042] Embodiment 3: with reference to instruction manual Figure 4-8 It can be seen that the difference between Embodiment 3 and Embodiments 1 and 2 is that the transmission mechanism includes gear 4, gear piece 401, rotating frame 5, snap ring 501, block 502, scraper 503, track 504 and air bag 505, and the gear 4 Rotate on the outside of the stirring bracket 102, the tooth piece 401 is embedded on the outside of the gear 4, the block 502 is rotated and fitted on the outside of the tooth piece 401, the snap ring 501 is installed on one side of the block 502, and the rotating frame 5 rotates on the block On one side of the ring 501, the scraper 503 slides on the upper end of the rotating frame 5, the track 504 is arranged above the inside of the rotating frame 5, and the airbag 505 is stretched on both sides of the rotating frame 5;

[0043] Wherein: gear 4, the two ends of gear 4 are inclined 25-45 ° and are set, and the inclined setting of gear 4 can avoid the ink from accum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com