Submerged-arc welding one-side welding double-side forming process

A single-sided welding double-sided, forming process technology, applied in arc welding equipment, welding equipment, manufacturing tools and other directions, can solve the problems of affecting welding quality, discontinuous welding seam, unsightly, etc., to improve the quality of double-sided forming, Avoid the effect of excessive height and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

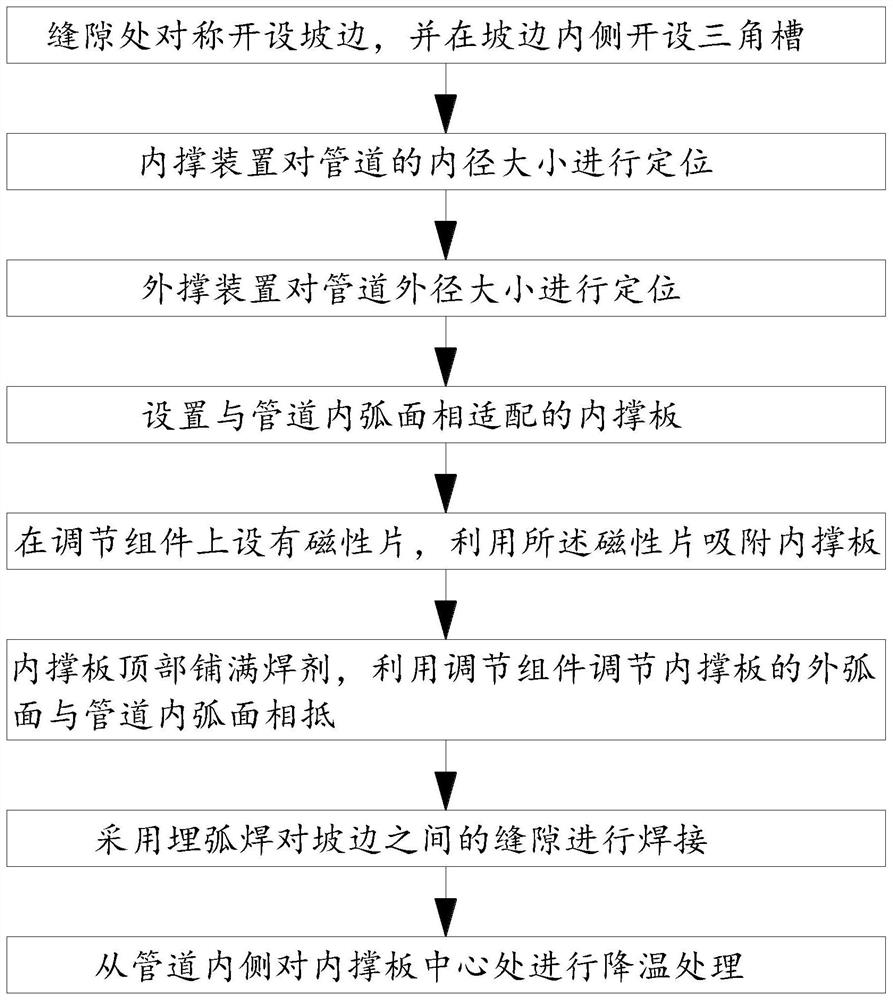

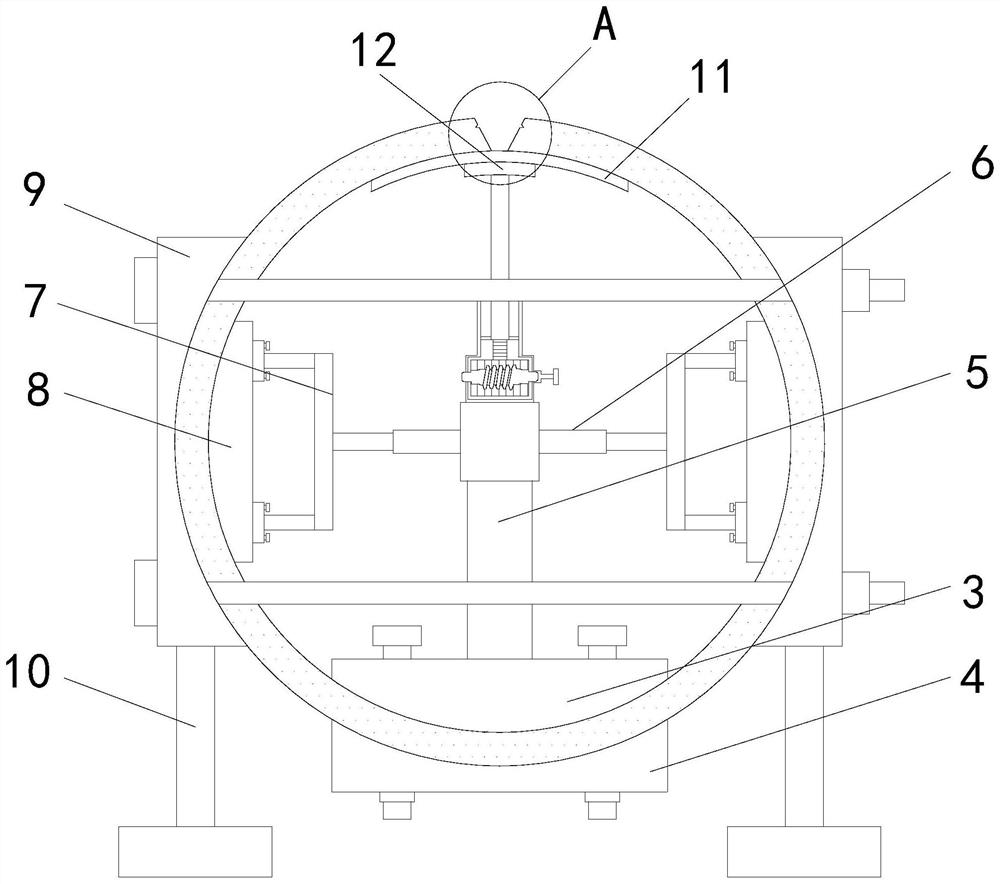

[0030] according to Figure 1-3 As shown, this embodiment proposes a submerged arc welding single-sided welding double-sided forming process, including the following steps:

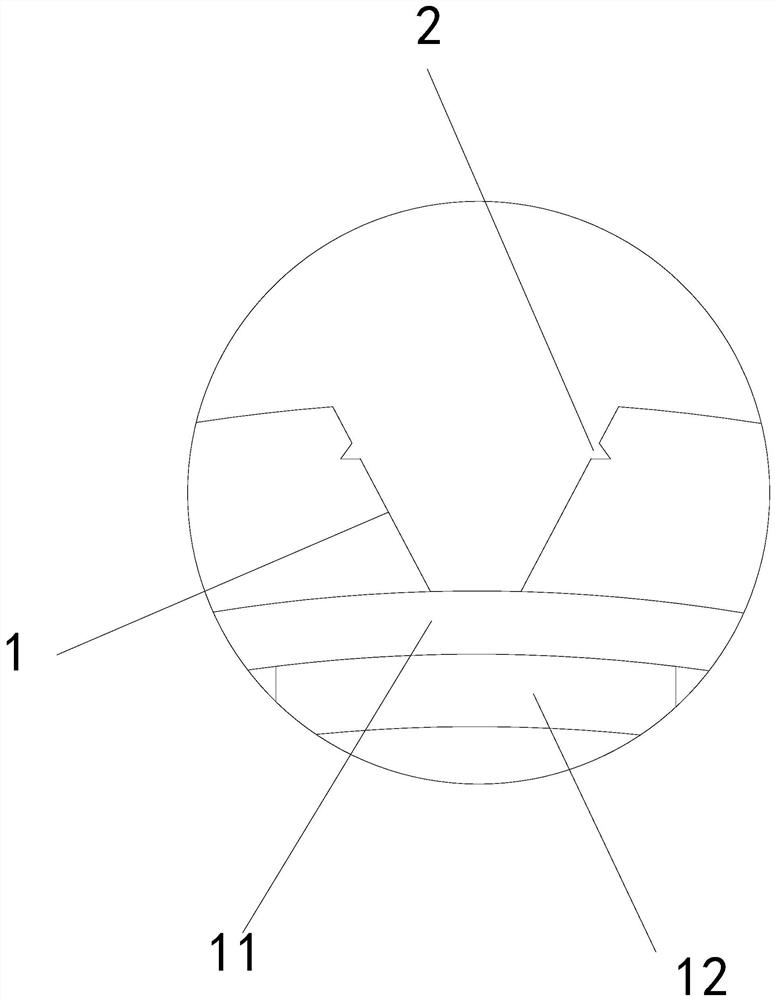

[0031] Step 1: Set up a slope 1 symmetrically at the gap of the pipeline, and set up a triangular groove 2 inside the slope 1, the angle between the two slopes 1 is 50°, and the angle of the triangular groove 2 is 35° , the triangular groove 2 is set at 2 / 3 of the total length of the slope 1, and then the slope 1 and the triangular groove 2 are pretreated, and the specific operations are: the slope 1 and the triangular groove 2 are removed and polished, and Wipe and clean slope 1 and triangular groove 23 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com