Vamp three-dimensional pattern forming method and vamp with three-dimensional pattern

A pattern forming and shoe upper technology, which is applied in the direction of shoemaking machinery, shoe uppers, footwear, etc., can solve the problems of pattern corrosion, difficulty in providing visual effects and three-dimensional sense, and falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

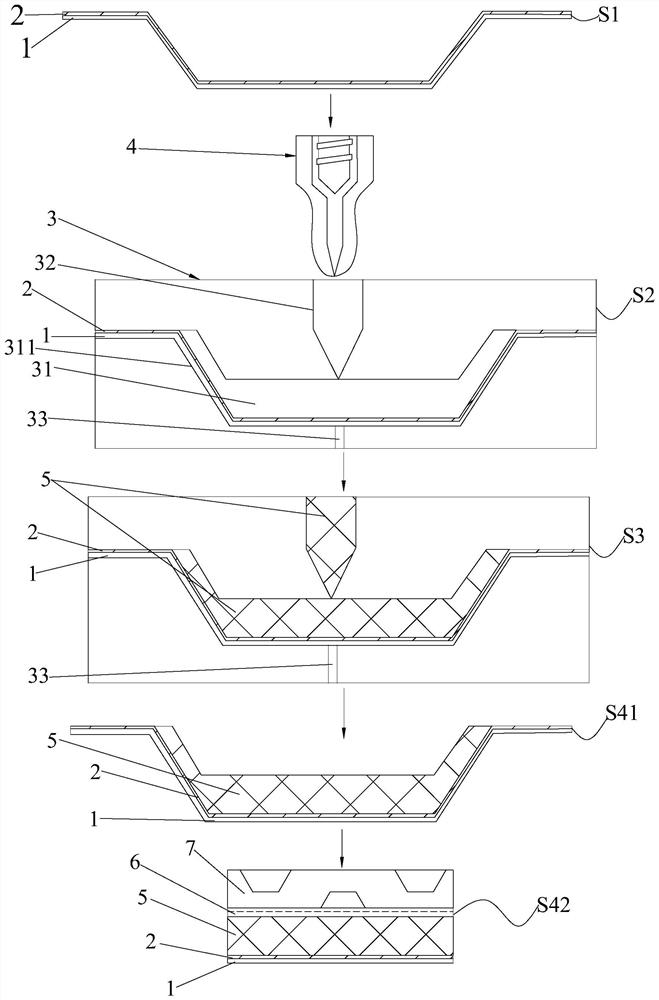

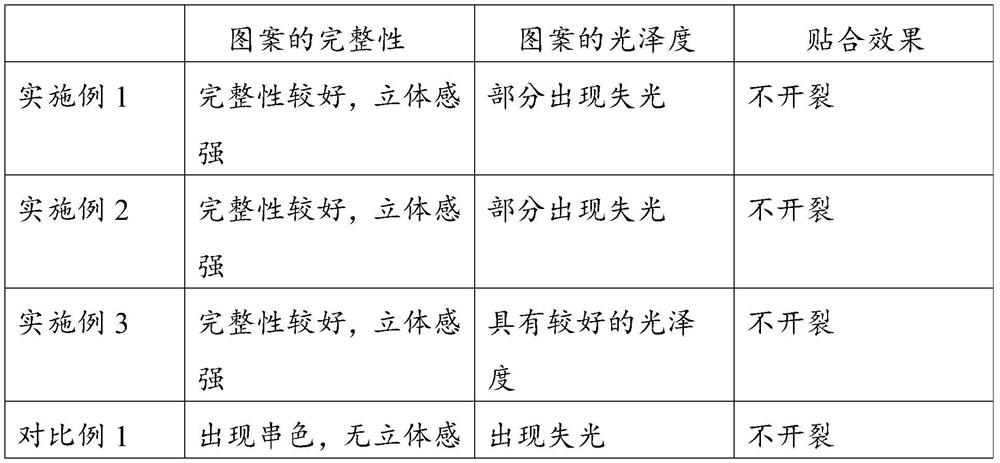

[0035] A method for forming a three-dimensional pattern on a vamp, characterized in that the steps include:

[0036] (1) Prepare a polyurethane thermoplastic film that matches the cavity of the mold, put the printing material into the barrel of the 3D printing device, design the 3D printing pattern in the computer system, and through the linkage between the 3D printing device and the computer system, the 3D The printed pattern is printed on the polyurethane thermoplastic film, wherein the polyurethane thermoplastic film includes 85 parts of TPU and 15 parts of PU in parts by mass, and the printed material includes 60 parts of polynylon and 0.4 parts of polyamide in terms of parts by mass. Ether-modified polysiloxane copolymer, 0.3 parts of fumed silica, 2 parts of pigment yellow, 1 part of pigment red and 0.8 parts of titanium dioxide;

[0037] (2) Put the polyurethane thermoplastic film with 3D printing pattern into the cavity of the mould. There is a vacuum flow channel insi...

Embodiment 2

[0041] A method for forming a three-dimensional pattern on a vamp, characterized in that the steps include:

[0042](1) Prepare a polyurethane thermoplastic film that matches the cavity of the mold, put the printing material into the barrel of the 3D printing device, design the 3D printing pattern in the computer system, and through the linkage between the 3D printing device and the computer system, the 3D The printed pattern is printed on the polyurethane thermoplastic film, wherein the polyurethane thermoplastic film includes 80 parts of TPU and 20 parts of PU in parts by mass, and the printed material includes 70 parts of polynylon and 0.6 parts of polyamide in terms of parts by mass. Ether-modified polysiloxane copolymer, 0.5 parts of fumed silica, 2 parts of pigment yellow, 2 parts of pigment red and 1.2 parts of titanium dioxide;

[0043] (2) Put the polyurethane thermoplastic film with 3D printing pattern into the cavity of the mold. There is a vacuum flow channel insid...

Embodiment 3

[0047] A method for forming a three-dimensional pattern on a vamp, characterized in that the steps include:

[0048] (1) Prepare a polyurethane thermoplastic film that matches the cavity of the mold, put the printing material into the barrel of the 3D printing device, design the 3D printing pattern in the computer system, and through the linkage between the 3D printing device and the computer system, the 3D The printed pattern is printed on the polyurethane thermoplastic film, wherein the polyurethane thermoplastic film includes 85 parts of TPU and 15 parts of PU in parts by mass, and the printed material includes 60 parts of polynylon and 0.4 parts of polyamide in terms of parts by mass. Ether-modified polysiloxane copolymer, 0.3 parts of fumed silica, 2 parts of pigment yellow, 1 part of pigment red, 0.8 parts of titanium dioxide, 1.5 parts of graphene and 4 parts of o-diallyl bisphenol A;

[0049] (2) Put the polyurethane thermoplastic film with 3D printing pattern into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com