Ceramic rock plate with glittering crystal diamonds and preparation method of ceramic rock plate

A technology for ceramics and slate, applied in the field of ceramic tile manufacturing, can solve the problems of lowering the whiteness of the bottom glaze layer of the crystal diamond glittering ceramic slate, increasing the cost of natural stone mining, reducing the glittering effect of the ceramic slate, etc., and achieving the glittering effect. Guarantee, ensure the reflectivity, reduce the effect of adding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

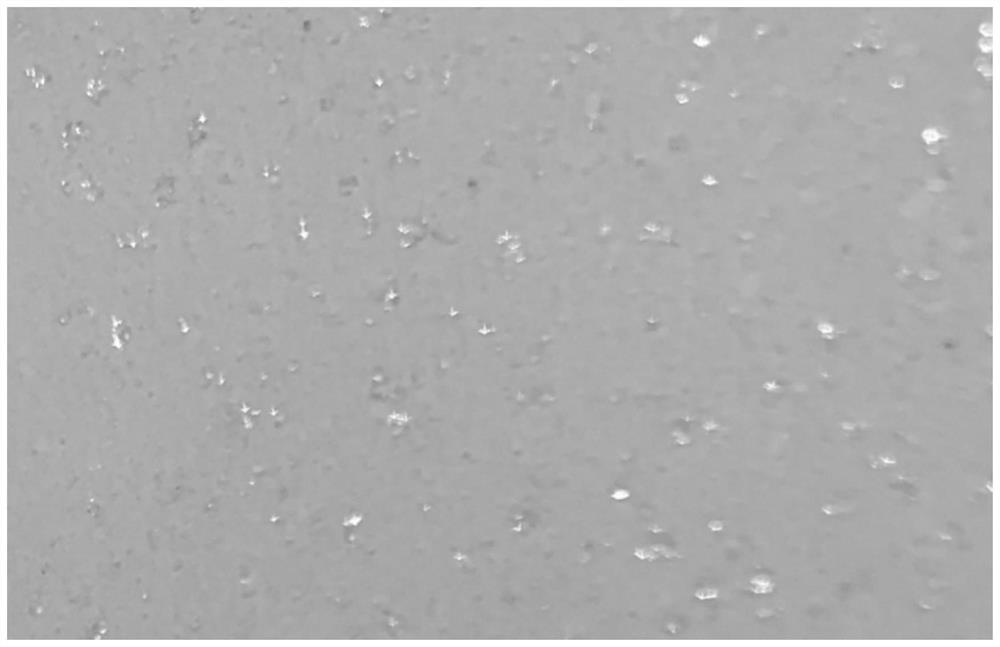

Embodiment 1

[0040]The structure of crystal diamond flashing ceramic rock plate is from bottom to top: body layer, bottom glaze layer, pattern layer, protective glaze layer, flash glaze layer; bottom glaze layer includes transparent frit, zirconium silicate, lead-containing ceramic waste, flash The glaze layer includes zircon sand. Leaded ceramic waste as PbZrO 3 , lead-containing ceramic scrap PbZrO 3 The purity is greater than 90%. The content of lead-containing ceramic waste is 5% by weight of the bottom glaze layer. The zirconium silicate content is 7% by weight of the bottom glaze layer. The chemical composition of the transparent frit, by weight percent, includes 54.80% SiO 2 , 17.69%Al 2 o 3 , 0.23% Fe 2 o 3 , 0.29%TiO 2 , 7.72% CaO, 4.37% MgO, 3.48% K 2 O, 3.14% Na 2 O, 8.28% loss on ignition. Lead-containing ceramic waste, zirconium silicate and transparent frit are all passed through a 325-mesh sieve.

[0041] A method for preparing a ceramic rock plate with crystal ...

Embodiment 2

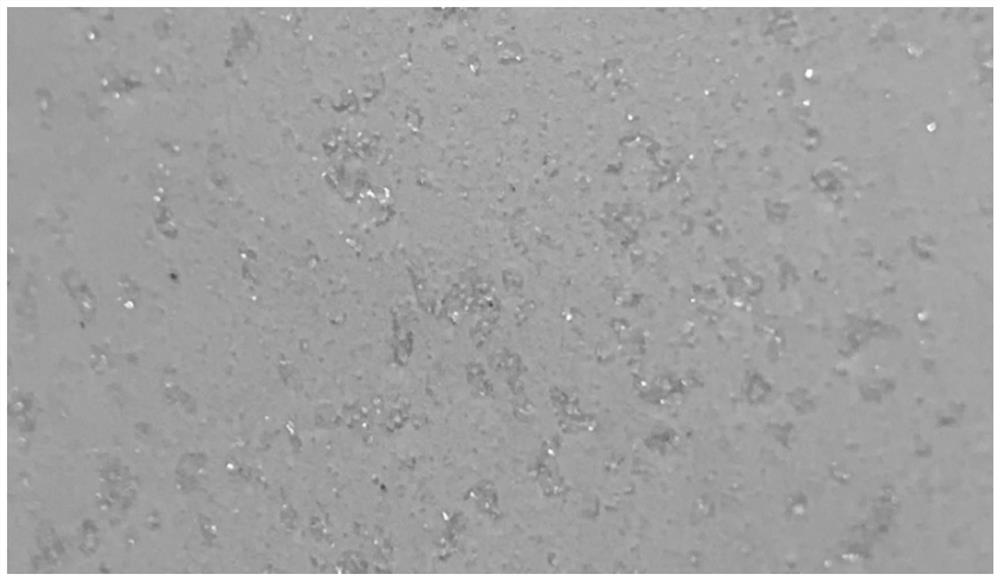

[0048] The structure of crystal diamond flashing ceramic rock plate is from bottom to top: body layer, bottom glaze layer, pattern layer, protective glaze layer, flash glaze layer; bottom glaze layer includes transparent frit, zirconium silicate, lead-containing ceramic waste, flash The glaze layer includes zircon sand. Leaded Ceramic Scrap as PbTiO 3 , lead-containing ceramic scrap PbTiO 3 The purity is greater than 90%. The content of lead-containing ceramic waste is 3% by weight of the bottom glaze layer. The zirconium silicate content is 9% by weight of the bottom glaze layer. The chemical composition of the transparent frit, by weight percent, includes 54.80% SiO 2 , 17.69%Al 2 o 3 , 0.23% Fe 2 o 3 , 0.29%TiO 2 , 7.72% CaO, 4.37% MgO, 3.48% K 2 O, 3.14% Na 2 O, 8.28% loss on ignition. Lead-containing ceramic waste, zirconium silicate and transparent frit are all passed through a 325-mesh sieve.

[0049] Preparation method of ceramic rock plate with crystal di...

Embodiment 3

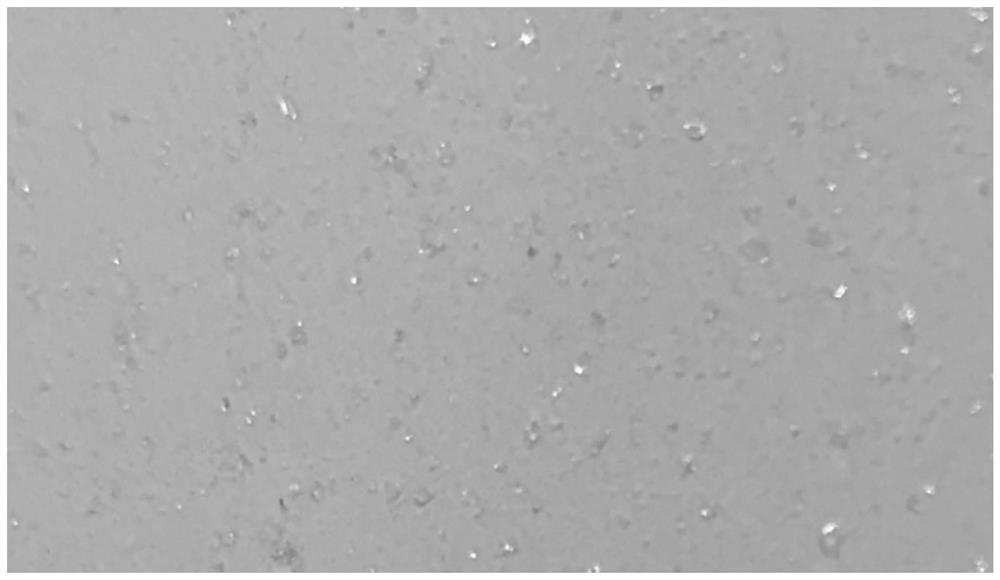

[0055] The structure of crystal diamond flashing ceramic rock plate is from bottom to top: body layer, bottom glaze layer, pattern layer, protective glaze layer, flash glaze layer; bottom glaze layer includes transparent frit, zirconium silicate, lead-containing ceramic waste, flash The glaze layer includes zircon sand. The three lead-containing ceramic wastes are PbTiO 3 , Pb(Zr,Ti)O 3 and Pb(Zr,Sn,Ti)O 3 , three lead-containing ceramic scraps PbTiO 3 , Pb(Zr,Ti)O 3 and Pb(Zr,Sn,Ti)O 3 The purity is greater than 90%. Three types of lead-containing ceramic waste by weight of the underglaze layer, PbTiO 3 Content is 1%, Pb(Zr,Ti)O 3 Content is 2%, Pb(Zr,Sn,Ti)O 3 The content is 1%. The zirconium silicate content is 8% by weight of the bottom glaze layer. The chemical composition of the transparent frit, by weight percent, includes 54.80% SiO 2 , 17.69%Al 2 o 3 , 0.23% Fe 2 o 3 , 0.29%TiO 2 , 7.72% CaO, 4.37% MgO, 3.48% K 2 O, 3.14% Na 2 O, 8.28% loss on igniti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com