Low-tightness carbonization-free solid electrolytic capacitor paper and preparation method and application thereof

A technology of electrolytic capacitor paper and solid electrolysis, which is applied in pulp beating method, paper, non-woody plant/crop pulp, etc., can solve the problems of less distribution of Manila hemp pulp and sisal pulp, increase cost, etc., so as to improve the quality of paper products. Formation value, energy saving and quality improvement, the effect of simplifying the process flow

Pending Publication Date: 2022-04-15

浙江凯恩新材料有限公司 +2

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] Manila hemp pulp and sisal pulp are usually used as hemp pulp fibers in the above two patents, but Manila he

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tightness | aaaaa | aaaaa |

| Tightness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Login to View More

Abstract

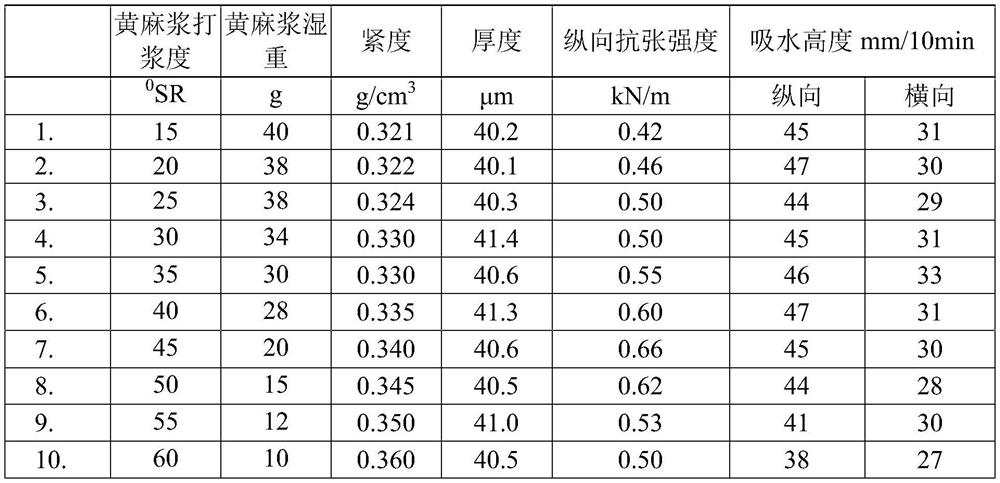

The invention belongs to the field of electrolytic capacitor paper, and particularly relates to low-tightness carbonization-free solid electrolytic capacitor paper and a preparation method and application thereof. The invention relates to low-tightness carbonization-free solid electrolytic capacitor paper, the tightness of the electrolytic capacitor paper is 0.32-0.38 g/cm < 3 >, and the electrolytic capacitor paper is prepared from the following components in percentage by dry weight: 40%-60% of jute pulp and 60%-40% of polyester fiber; the beating degree of the jute pulp is 35-55 degrees SR, the wet weight of the jute pulp is 10-30 g, the pulp forming mass percent concentration after pulp grinding is 2.0-3.5%, the length of the polyester fibers is 2-10 mm, and the fineness of the polyester fibers is 0.1-3 dtex; the electrolytic capacitor paper is made by adopting a rotary screen forming paper machine, the speed of the paper machine is 80-120m/min, the mass percent concentration of upper screen pulp flow is 0.01-0.2%, a pulp homogenizing roller is arranged at the bottom of a pulp inlet flow channel of a rotary screen forming device, and the clockwise rotating speed of the pulp homogenizing roller is 35-50R/min. The tensile strength of the paper and the uniformity value of the paper are improved, and the production requirements and the performance requirements of downstream customers on the paper are met.

Description

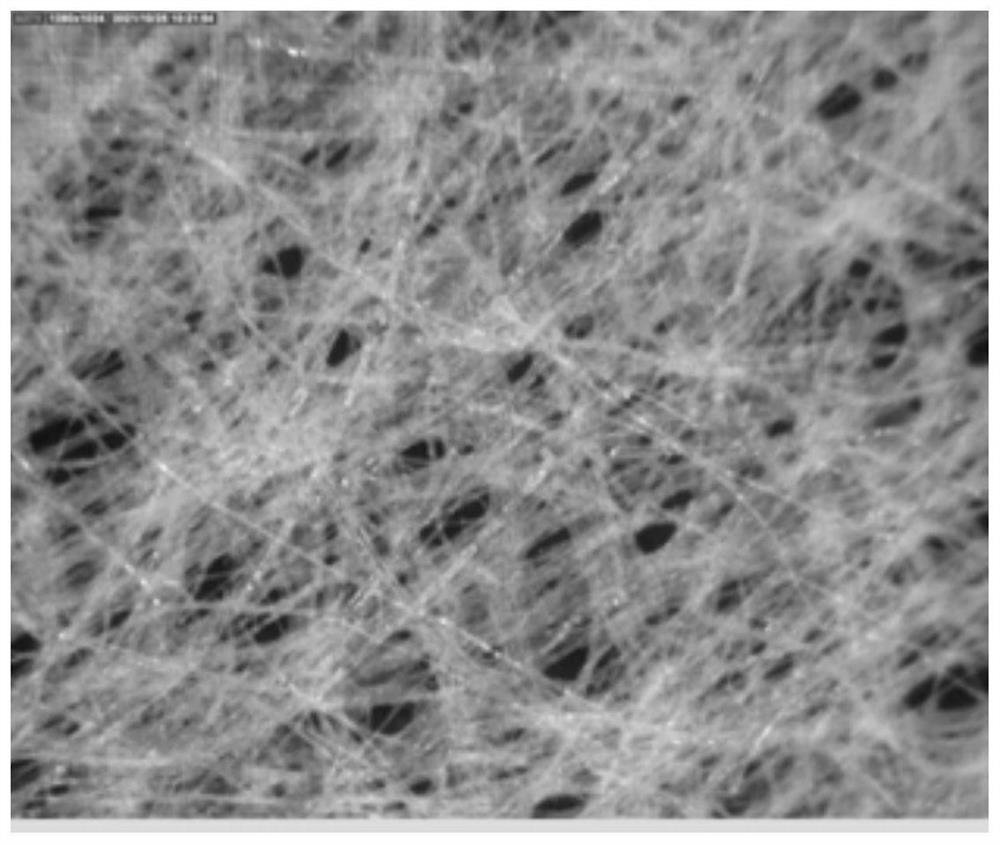

technical field [0001] The invention belongs to the field of electrolytic capacitor paper, and in particular relates to a low-density carbonization-free solid electrolytic capacitor paper and a preparation method and application thereof. Background technique [0002] The electrolyte in a solid electrolytic capacitor is a solid conductive polymer material. The structure of a solid electrolytic capacitor includes an anode, a cathode, electrolytic paper, and a solid conductive polymer material. Electrolytic capacitor paper is one of the indispensable raw materials for the preparation of electrolytic capacitors. In capacitors, it is mainly used to absorb conductive polymer monomers and oxidants to form polymers. short circuit. [0003] The traditional electrolytic capacitor paper is all cellulose material, which has a weak adsorption capacity for monomers. At the same time, cellulose contains a large number of hydroxyl groups, which will cause side reactions during the polymeri...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21H11/12D21H13/24D21D1/02

Inventor 邵卫勇李南华左磊刚张文超何江郑伟峰郭婉

Owner 浙江凯恩新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com