Tube bundle

A technology for hoses and inner sleeves, applied in the direction of hoses, pipes, pipe components, etc., can solve the problems of reducing construction efficiency, increasing construction time, and poor pressure bearing capacity, so as to improve construction efficiency, reduce construction costs, and reduce pressure high level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

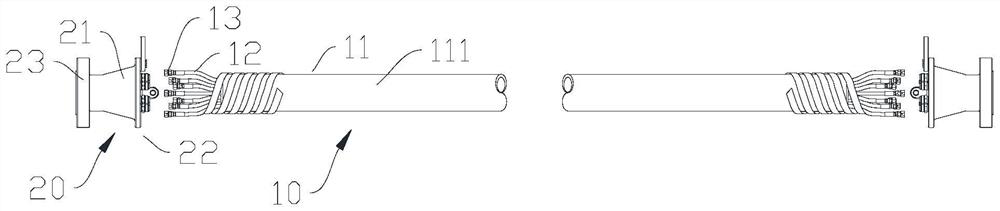

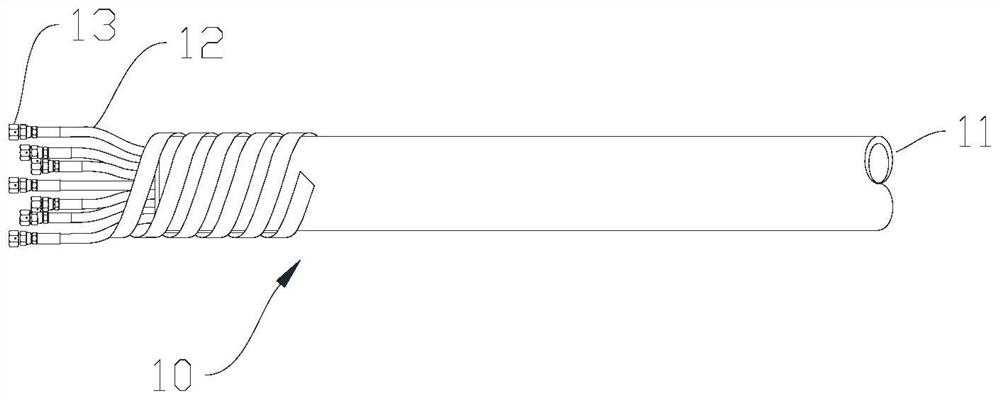

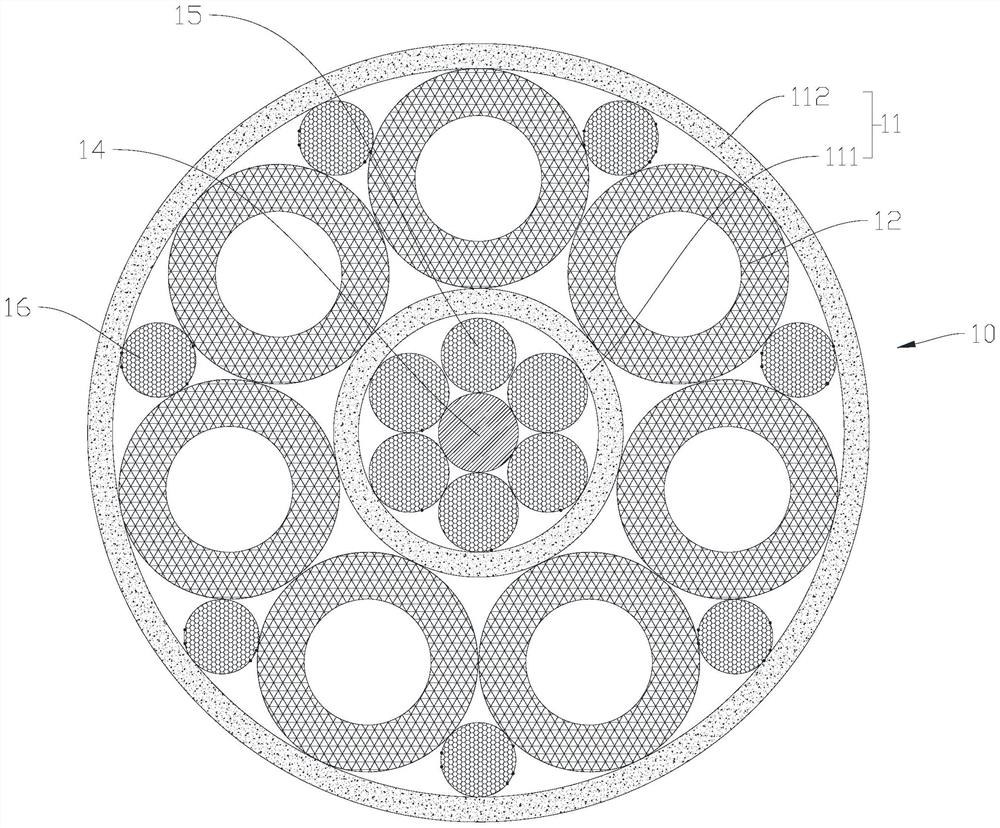

[0027] figure 1 Some preferred embodiments of the tube bundles of the invention are shown. The tube bundle can have the function of anti-crushing, and it has the characteristics of high pressure rating, light weight, large flow rate, small curvature radius and flexible and replaceable end joints. The tube bundle can be used as the central bridge between the steel pipe of the "steel coil laying drive device" and the deep-water pre-commissioning module, which can realize pre-commissioning operations at greater water depths and diversification of deep-water pre-commissioning operations, greatly reducing construction costs , Improve the construction efficiency and meet the high pressure and high flow requirements of deep w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com