Advanced coal blending combustion system and coal blending combustion method for coal-fired generator set

A technology for generating sets and coal blending, which is applied in the combustion method, combustion control, combustion equipment and other directions, can solve the problems of increased coking and ash accumulation in the furnace, affecting the safety of the unit, and the incompatibility of boilers and auxiliary equipment with coal combustion. To achieve the effect of reducing the cost of coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

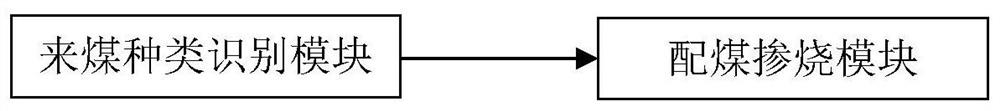

[0032] Such as figure 1 As shown, an advanced coal blending and blending combustion system for a coal-fired generating set includes a coal type identification module and a coal blending blending module.

[0033] The incoming coal type identification module is used to identify the incoming coal types of different grinding groups. The incoming coal types include Wannian anthracite, Yangquan anthracite, market coal, Lu'an lean coal, and high-sulfur high-heat coal.

[0034] Coal blending and blending module is used to count the types of incoming coal, calculate the proportion of each coal type, and adjust the blending ratio of different coal types according to the constraints; the constraints include the upper and lower limits of the load range, the upper limit of the blending ratio of anthracite into the mill, and the high calorific value coal. The lower limit of the proportion of blended combustion into the grinding mill, the set value of raw coal consumption and the inlet SO 2...

Embodiment 2

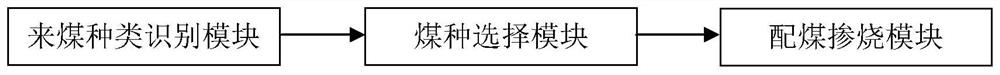

[0037] Such as figure 2 As shown, an advanced coal blending and blending combustion system for a coal-fired power generation unit includes an incoming coal type identification module, a coal type selection module, and a coal blending blending combustion module.

[0038] The incoming coal type identification module is used to identify the incoming coal types of different grinding groups; the coal type selection module receives the identification results of the incoming coal type identification module, marks different coal types according to the identification results, and inputs the different coal types into the coal blending and blending module, The proportion of each coal type is calculated and counted by the coal blending and burning module.

[0039] Coal blending and blending module is used to count the types of incoming coal, calculate the proportion of each coal type, and adjust the blending ratio of different coal types according to the constraints; the constraints incl...

Embodiment 3

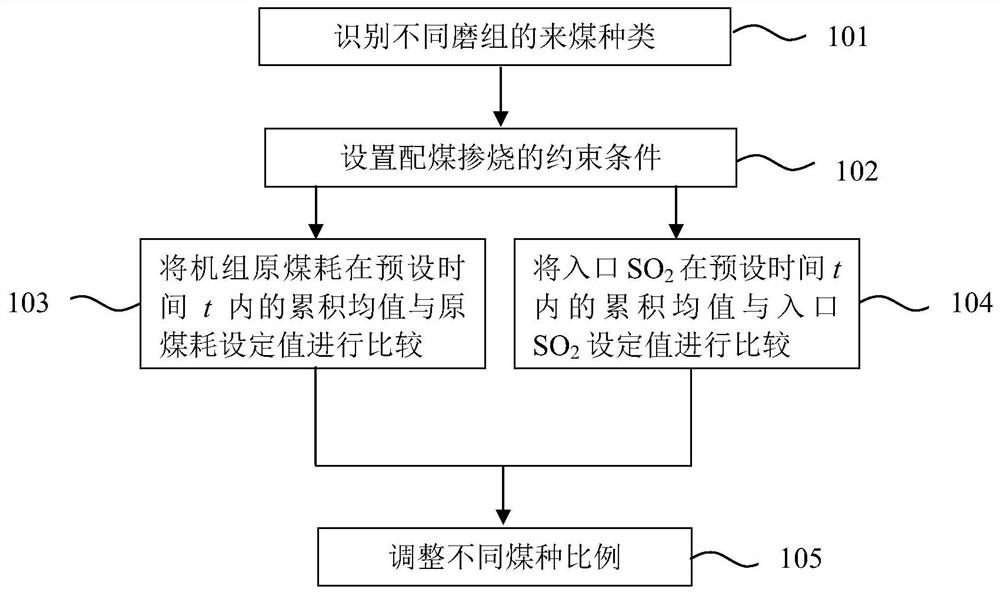

[0043] The process of coal blending and blending by using the advanced coal blending and blending system of the above-mentioned coal-fired power generation unit is as follows: image 3 shown, including the following steps:

[0044] S101: Identify incoming coal types of different grinding groups, calculate the ratio of each coal type, and obtain the initial blending ratio; in the initial blending ratio, the ratios of Wannian anthracite and Yangquan anthracite are the same;

[0045] S102: according to incoming coal type, set the constraint condition of coal blending and blending;

[0046] S103: comparing the cumulative mean value of the raw coal consumption of the unit within the preset time t with the set value of the raw coal consumption;

[0047] S104: set the entrance SO 2 The cumulative mean and the inlet SO over a preset time t 2 set value for comparison;

[0048] S105: According to the comparison results of S103 and S105, adjust the proportion of different coal types ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com