Material conveying device and method for solid waste coupling combustion

A conveying device and material technology, which is applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of unstable operation of the material conveying device, easy blockage of the material conveying device, and small adjustable flow range, so as to improve the operation accuracy and The range of flow regulation, the effect of saving operating costs and energy consumption, and shortening the mixing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

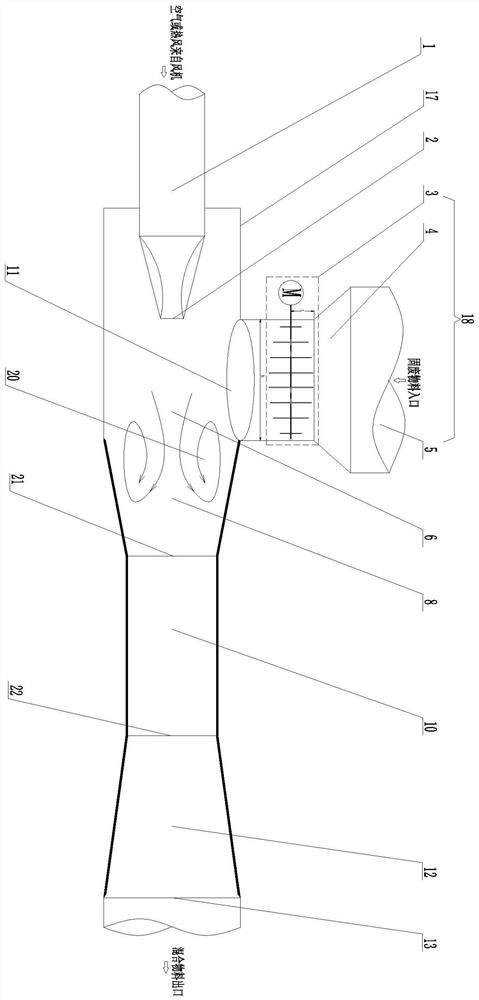

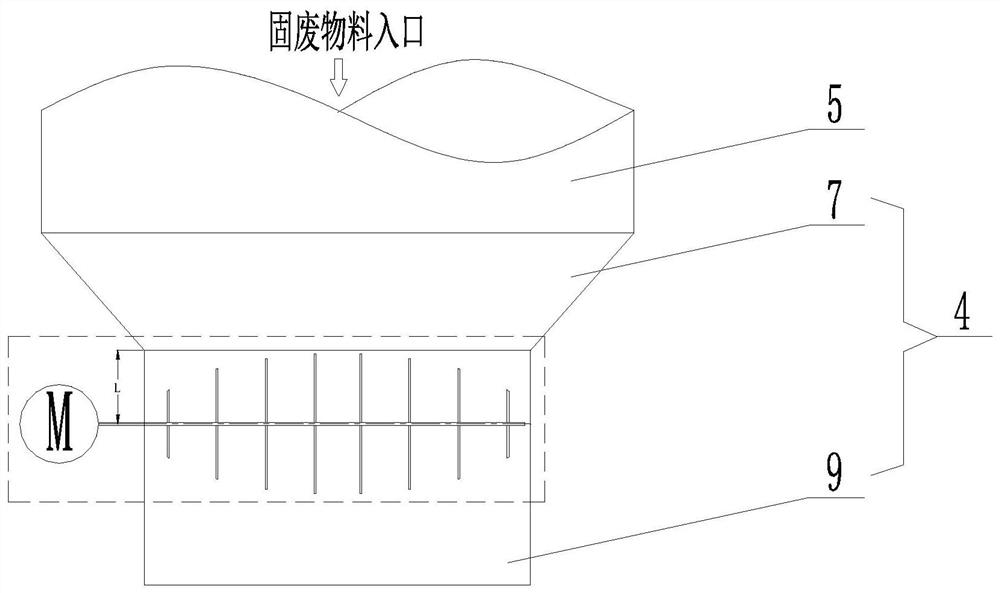

[0034] Embodiment 1 of the present invention: a material conveying device for coupled combustion of solid waste, including a high-pressure air inlet pipe 1, a high-pressure air nozzle 2, and a material receiving device 17. The air inlet pipeline 1 is arranged on the material receiving device 17, and is positioned at one side of the material introducing device 18. The high-pressure air nozzle 2 is connected with the high-pressure air inlet pipeline 1 and arranged inside the material receiving device 17. The material receiving device 17 includes a material inlet 11 , the high-pressure air nozzle 2 is located on the side of the material inlet 11 and below the material inlet 11 , the material receiving device 17 is connected to the mixing pipe 10 , and the mixing pipe 10 is connected to the diffuser pipe 12 .

Embodiment 2

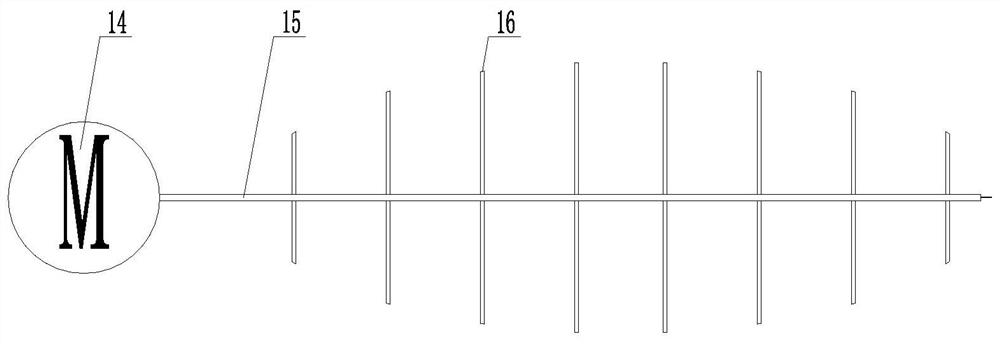

[0035] Embodiment 2 of the present invention: a material conveying device for coupled combustion of solid waste, comprising a high-pressure air inlet pipe 1, a high-pressure air nozzle 2, and a material receiving device 17. The material receiving device 17 is provided with a material introducing device 18, and the high-pressure The air inlet pipeline 1 is arranged on the material receiving device 17, and is positioned at one side of the material introducing device 18. The high-pressure air nozzle 2 is connected with the high-pressure air inlet pipeline 1 and arranged inside the material receiving device 17. The material receiving device 17 includes a material inlet 11 , the high-pressure air nozzle 2 is located on the side of the material inlet 11 and below the material inlet 11 , the material receiving device 17 is connected to the mixing pipe 10 , and the mixing pipe 10 is connected to the diffuser pipe 12 . Wherein, material introduction device 18 comprises anti-bypass devic...

Embodiment 3

[0036] Embodiment 3 of the present invention: a material conveying device for coupled combustion of solid waste, including a high-pressure air inlet pipe 1, a high-pressure air nozzle 2, and a material receiving device 17. The material receiving device 17 is provided with a material introducing device 18, and the high-pressure The air inlet pipeline 1 is arranged on the material receiving device 17, and is positioned at one side of the material introducing device 18. The high-pressure air nozzle 2 is connected with the high-pressure air inlet pipeline 1 and arranged inside the material receiving device 17. The material receiving device 17 includes a material inlet 11 , the high-pressure air nozzle 2 is located on the side of the material inlet 11 and below the material inlet 11 , the material receiving device 17 is connected to the mixing pipe 10 , and the mixing pipe 10 is connected to the diffuser pipe 12 . Wherein, material introduction device 18 comprises anti-bypass device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com