Longitudinal Longwall Planing and Milling Trough Mining Method in Steeply Inclined Coal Seam

A mining method and steeply inclined technology, applied in the field of steeply inclined coal seam mining, can solve the problems of difficulty in controlling the surrounding rock of the working face, large energy loss of the production system, and affecting the production safety of the working face, so as to ensure the sustainable exploitation and utilization of resources, Effects of saving water and electricity consumption and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

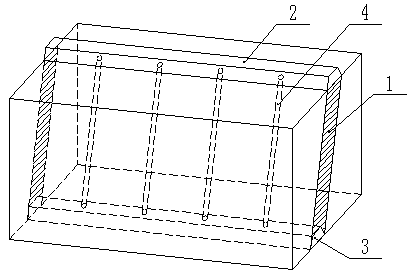

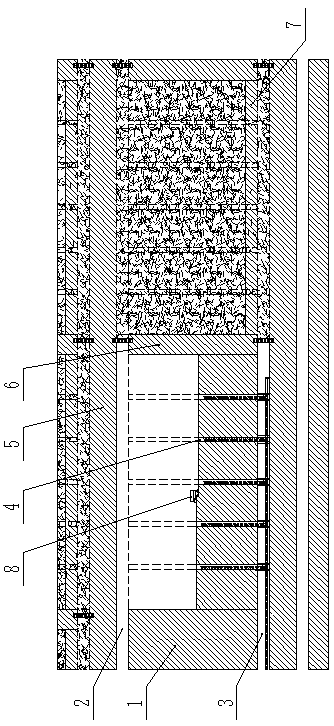

[0024] Such as figure 1 , figure 2 As shown, if the roof and floor of the steeply inclined coal seam 1 have good stability and good storage conditions, the longitudinal longwall planing and milling of the sharply inclined coal seam of the present invention will proceed according to the following steps:

[0025] The first step is to analyze the mechanical characteristics of the coal seam and surrounding rock according to the occurrence conditions of the steeply inclined coal seam 1, and reasonably determine the mining width, stage height, strike length, protective coal pillars 6 between adjacent mining areas, and protective coal pillars between adjacent stages The main technical parameters of the 5th grade coal mining face. According to these technical parameters, the mining roadways are arranged in the upper and lower parts of the coal seam according to the stage height of 20-40m;

[0026] In the second step, according to the main technical parameters of the coal mining face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com